Composite Tank - FRP Tanks and Vessels with High Mechanical Strength in Various Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

INSTRUCTION

FRP tanks and vessels can be largely used in many areas of the light industry, petroleum, chemical, food brewing, transportation and so on. Such product can resist the corrosion of various acids, alkalis and salts.

CHARACTERISTICS

• High mechanical strength

• High mechanical inertness

• Resistance to weathering

• Low thermal and electrical conductivity

• Long Life

• Non-toxicity

• No need for maintenance

• Light weight

DESIGN PHILOSOPHY

The correct structuring of any kind of G.R.P. tank consist of three distinct types of layers:

• Chemical Resistant Layer

• Mechanically Resistant Layer

• Outer Protective Layer

OTHER DESIGN CONDITIONS

• Working pressure, Vacuum

• Support span

• Working temperature

CHEMICAL RESISTANCE

Resistance to corrosion in aggressive environments is one of

the primary reasons for specifying GRP tanks. These, resists a

wide range of chemicals and temperatures and can be built to

provide additional abrasion, weathering and fire resistance. The

chemical resistance of GRP tank depends primarily on the resin/

glass matrix used. Other factors can affect laminate resistance

including liner construction, cure, and fabrication methodology

and installation techniques.

General corrosion, galvanic, aerobic, pitting, dezincification,

graphitic and intergranular corrosion harm metals but not GRP.

PRODUCTION RANGE

FRP small-scale storage tank: Diameter ≤ 4M

Large-scale jobsite winding vertical storage tank: Diameter 4200mm-25000mm

EXECUTIVE STANDARD

FRP small-scale storage tank

JC/T587-1995 (Glass fiber reinforced plastic storage tank)

Large-scale storage tank

HG/T3983-2007 Industry standards of Chemical Corrosion-resistant jobsite Winding FRP Large-scale storage tank

HG/T20696 Design Requirements of FRP Chemical Equipment

COMPANY INTRODUCTION

CNBM, China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

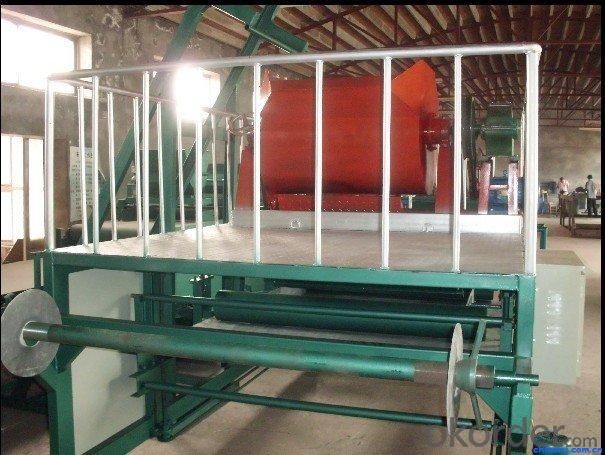

PICTURE S

- Q: What are the manufacturing processes of FRP tanks?

- In order to increase the strength and stiffness of the tank and to improve the surface performance of the tank, the longitudinal lining must be wrapped around the qualified lining surface. The thickness of the wrapping layer is determined by the design of the internal pressure, determined by the diameter, the pressure and the safety factor.

- Q: What is the wall thickness of FRP vertical tanks?

- That's the industry standard. It's perfectly OK to calculate in that way, and the calculated thickness is generally too thick.

- Q: What are the manufacturers of glass fibre reinforced plastic storage tanks in Guangdong?

- The main production equipment 3: one for the introduction of Italy and Venus, with the international standards of fiber winding production line, the production of various series of FRP mixing tanks, FRP tanks, pipes, containers and assembled tank, sand tube, cable protection tube, composite tank, absorption tower, non-standard equipment etc. and the production of products with high strength, corrosion resistance, non-toxic and tasteless, adaptability and strong features, has been widely used in chemical industry, metallurgy, pharmaceutical, electronics, food brewing, municipal construction and other industries.

- Q: What kind of material can be used to store the dilute hydrochloric acid containing toluene?

- What kind of material can be used to store the dilute hydrochloric acid containing toluene?

- Q: What are the maintenance methods of FRP tanks?

- FRP tanks have two molding methods: 1. hand paste molding, resin glass cloth, hand paste molding.

- Q: Does anyone know the wall thickness of 10m3 FRP tanks?

- 1m3's no more than 10MM, and others I'd like to know.

- Q: What kind of industry does GRP storage tank belong to?

- FRP tanks are divided into horizontal mechanical winding FRP tanks, glass fiber reinforced plastic horizontal storage tanks, vertical storage tanks, vertical storage tanks, transport tanks, reaction tanks, various chemical equipment, containers and large series of containers

- Q: Tank leakage how to do, glass fiber reinforced plastic repair, tank maintenance, after-sales service?

- Cooling tower cleaning and replacement packing, maintenance water distributor, maintenance glass fiber reinforced plastic panel. Maintenance of glass fiber reinforced plastic cable tray. Repair and maintenance of various FRP tower, glass steel tank, a water tank, nitrogen sealed water tanks.

- Q: The production process of FRP tanks

- Filament winding, pultrusion and hot pressing, etc..

- Q: Why should the hydrochloric acid storage tank be lined?

- Hydrochloric acid storage tank lined tank, because the material is a metal (usually steel and Bai Gang), the material is not resistant to acid corrosion, and lined with plastic material (usually PP, PE, PHFE etc.), the lining material of hydrochloric acid, and flexible, easy system as lining.

Send your message to us

Composite Tank - FRP Tanks and Vessels with High Mechanical Strength in Various Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords