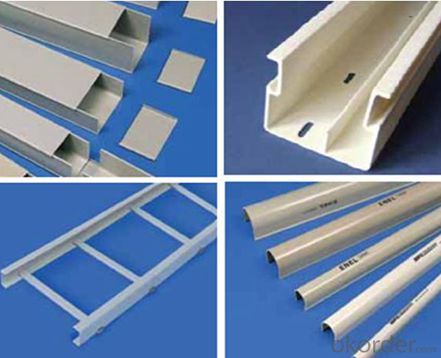

FRP Pultrusion Profiles - Lightweight and High Strength FRP Pultruded Gratings in Various Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 watt

- Supply Capability:

- 100000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DESCRIPTION

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

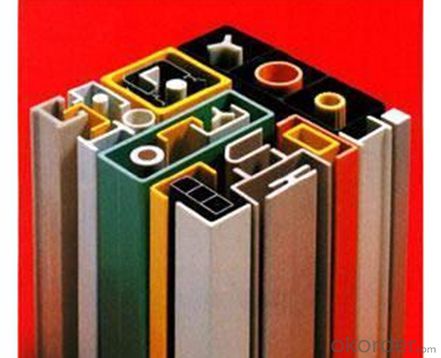

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenol resin

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

PICTURES

- Q: What are the typical applications of FRP pultrusion profiles?

- FRP pultrusion profiles possess unique properties that make them applicable in various fields. Examples of their typical uses include: 1. Construction and Infrastructure: FRP profiles serve as structural elements in buildings, bridges, and infrastructure projects. They are commonly employed for beams, columns, decks, and reinforcement due to their impressive strength-to-weight ratio, resistance to corrosion, and durability. 2. Industrial and Chemical Processing: The industrial sector heavily utilizes FRP profiles for platforms, walkways, ladders, and handrails. These profiles exhibit excellent resistance to chemicals, heat, and corrosion, making them well-suited for harsh environments. 3. Electrical and Telecommunication: FRP profiles find utility in electrical and telecommunication systems, fulfilling roles such as cable trays, ladder racks, and support structures. They provide electrical insulation and are non-conductive, ensuring safety and reliability in these applications. 4. Transportation: The transportation industry benefits from FRP profiles, particularly in the production of lightweight components for vehicles like buses, trains, and trucks. These profiles aid in weight reduction, improve fuel efficiency, and enhance overall vehicle performance. 5. Marine and Offshore: FRP pultrusion profiles excel in marine and offshore applications due to their resistance to saltwater, UV radiation, and harsh environmental conditions. They are employed in boat hulls, piers, dock fenders, and other offshore structures. 6. Recreation and Sports: FRP profiles contribute to the production of recreational equipment like ladders, slides, playground equipment, and sports accessories. Their strength, durability, and weather resistance make them ideal for these applications. 7. Water Treatment and Wastewater Management: FRP profiles find extensive use in water treatment plants, sewage systems, and wastewater management facilities. They fulfill roles such as grating, handrails, ladders, and other structural components due to their resistance to chemicals and corrosion. In summary, the versatility, strength, corrosion resistance, and lightweight nature of FRP pultrusion profiles make them suitable for diverse applications in various industries.

- Q: Are FRP pultrusion profiles resistant to vibration or shock?

- Yes, FRP pultrusion profiles are generally resistant to both vibration and shock due to their high strength-to-weight ratio and excellent damping properties. The composite materials used in their construction, such as fiberglass and resin, offer excellent resistance to vibrations and mechanical shocks, making them ideal for applications where such conditions are present.

- Q: Are FRP pultrusion profiles resistant to impact from heavy machinery?

- FRP pultrusion profiles are generally known for their high strength-to-weight ratio and excellent mechanical properties, which make them resistant to various external impacts. However, the specific resistance to impact from heavy machinery depends on several factors. Firstly, the design and composition of the FRP pultrusion profiles play a vital role in determining their impact resistance. Different manufacturers may use various reinforcement materials, such as fiberglass, carbon fiber, or other composites, which can significantly affect the profiles' ability to withstand heavy machinery impacts. Additionally, the thickness and overall dimensions of the FRP profiles contribute to their impact resistance. Thicker profiles tend to provide higher resistance to impact loads compared to thinner ones. Moreover, profiles with reinforced sections or additional layers for structural integrity can further enhance their impact resistance. It is also essential to consider the specific application and the magnitude of impact expected from heavy machinery. While FRP pultrusion profiles can generally withstand moderate to high impacts, extreme forces or heavy machinery with substantial weight may still cause damage. In such cases, additional protective measures like using impact-resistant coatings or reinforcing the profiles with metal inserts may be necessary. Overall, FRP pultrusion profiles exhibit good resistance to impact from heavy machinery due to their inherent strength and durability. However, it is always recommended to consult with the manufacturer or a structural engineer to ensure the profiles meet the specific requirements of the application and machinery involved.

- Q: Can FRP profiles replace carbon steel profiles?

- I am a man of glass fiber reinforced material. Honestly, "I can't do it."". Can be used in buildings, such as insulation, corrosion protection, aging resistance, flame retardant, etc.,

- Q: Can FRP pultrusion profiles be used in agricultural applications?

- Indeed, FRP pultrusion profiles are applicable in the field of agriculture. Renowned for their remarkable strength-to-weight ratio, resistance to corrosion, and durability, FRP pultrusion profiles are an ideal choice for a variety of agricultural uses. One common utilization of FRP pultrusion profiles in agriculture is the construction of livestock enclosures, encompassing fences, gates, and pens. These profiles possess outstanding resistance to weather conditions, chemicals, and degradation caused by UV rays, ensuring their long-lasting performance in outdoor environments. Furthermore, their lightweight composition facilitates ease of handling and installation. Moreover, FRP pultrusion profiles find application in the production of agricultural equipment and machinery. They can be employed for structural components, such as beams and supports, as well as functional parts like handles, brackets, and covers. The impressive strength of FRP profiles enables them to withstand heavy loads and challenging operating conditions, while their resistance to corrosion guarantees their longevity in corrosive surroundings such as fertilizer storage areas or livestock waste management systems. Additionally, FRP pultrusion profiles can be utilized for irrigation systems in agriculture. Their non-conductive nature renders them perfect for situations requiring electrical insulation, such as the creation of irrigation pipes or channels. Furthermore, the corrosion resistance of FRP profiles ensures their ability to endure exposure to water, chemicals, and fertilizers frequently employed in agricultural irrigation. To summarize, FRP pultrusion profiles exhibit exceptional suitability for agricultural applications due to their high strength, resistance to corrosion, and durability. Whether employed in livestock enclosures, agricultural machinery, or irrigation systems, FRP profiles offer numerous advantages that position them as a reliable choice within the agricultural industry.

- Q: Can FRP pultrusion profiles be used in the construction of wastewater treatment tanks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be effectively used in the construction of wastewater treatment tanks. FRP pultrusion profiles are known for their high strength-to-weight ratio, corrosion resistance, and durability, making them an ideal choice for applications in harsh environments such as wastewater treatment facilities. FRP pultrusion profiles are made by pulling continuous fibers, typically glass or carbon, through a resin bath and then through a heated die to form the desired shape. This process results in profiles with consistent cross-sections and excellent mechanical properties. In the construction of wastewater treatment tanks, FRP pultrusion profiles can be used for a variety of purposes. They can be employed as structural elements, such as beams, columns, and bracing systems, providing the necessary strength and stiffness to support the tank structure. FRP profiles can also be used as reinforcement in concrete structures, enhancing their durability and resistance to chemical attack from the wastewater. Furthermore, FRP pultrusion profiles can be designed to resist the corrosive effects of the chemicals and gases present in wastewater treatment tanks. Unlike traditional materials like steel or concrete, FRP is highly resistant to corrosion, ensuring a longer service life and reduced maintenance costs. Additionally, FRP profiles offer advantages in terms of installation and transportation. They are lightweight, allowing for easier handling and reduced labor requirements during construction. The modular nature of FRP profiles also facilitates quick assembly and disassembly, making maintenance and modifications more convenient. Overall, the use of FRP pultrusion profiles in the construction of wastewater treatment tanks provides numerous benefits, including high strength, corrosion resistance, durability, and ease of installation. These advantages make FRP a reliable and cost-effective choice for wastewater treatment facilities.

- Q: Are FRP pultrusion profiles fire resistant?

- Yes, FRP pultrusion profiles are fire resistant.

- Q: Are FRP pultrusion profiles resistant to moisture absorption?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to moisture absorption. This is due to the nature of the material used in their construction, which typically includes a combination of fiberglass and resin. Fiberglass is inherently non-porous and does not absorb moisture, while the resin used in FRP pultrusion profiles is specifically formulated to be moisture-resistant. The pultrusion process used to manufacture FRP profiles also contributes to their moisture resistance. During pultrusion, the fiberglass and resin are pulled through a heated die, which not only ensures thorough impregnation of the fibers with resin but also creates a solid, dense structure. This results in a product that is highly resistant to water penetration and moisture absorption. Furthermore, FRP pultrusion profiles can be further enhanced with the addition of protective coatings or surface treatments, such as gel coats or UV-resistant finishes, which provide an additional barrier against moisture ingress. The moisture resistance of FRP pultrusion profiles makes them an excellent choice for applications where exposure to water or high humidity is expected, such as in marine environments, wastewater treatment plants, or outdoor structures. Their resistance to moisture absorption helps to prevent issues like rot, rust, or degradation commonly associated with other materials like wood or metal. Overall, FRP pultrusion profiles offer a reliable and durable solution that can withstand moisture exposure without compromising their structural integrity or performance.

- Q: Are FRP pultrusion profiles resistant to fungi and mold?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to fungi and mold. This is due to the non-porous nature of the materials used in their construction, such as fiberglass and epoxy resins. These materials do not provide a suitable environment for fungi and mold to grow, making FRP pultrusion profiles highly resistant to their growth and colonization. Furthermore, FRP pultrusion profiles are inherently moisture-resistant, which is another factor that discourages the growth of fungi and mold. Unlike traditional materials like wood, which can absorb moisture and provide a conducive environment for fungal and mold growth, FRP profiles do not absorb water and are therefore highly resistant to these issues. The combination of non-porous materials and moisture resistance makes FRP pultrusion profiles a suitable choice for applications where fungi and mold resistance is crucial, such as in humid or damp environments. However, it is important to note that no material is entirely immune to fungi and mold growth under all circumstances. In certain extreme conditions, where there is prolonged exposure to high levels of moisture and organic matter, it is still possible for some fungi and mold to colonize FRP profiles. However, compared to other materials, FRP pultrusion profiles offer a significantly higher level of resistance to these issues.

- Q: Can FRP pultrusion profiles be used in the automotive manufacturing industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the automotive manufacturing industry. FRP pultrusion profiles offer several advantages that make them suitable for automotive applications. Firstly, FRP profiles are lightweight, which helps in reducing the overall weight of the vehicle. This is crucial for improving fuel efficiency and reducing emissions. The lighter weight of FRP profiles also allows for better handling and improved performance. Secondly, FRP profiles possess excellent mechanical properties such as high strength and stiffness. This makes them suitable for use in structural components of vehicles, such as chassis, body panels, and frames. FRP profiles can withstand heavy loads and offer good impact resistance, ensuring the safety of the vehicle and its occupants. Additionally, FRP profiles exhibit excellent corrosion resistance, which is particularly beneficial for automotive applications. Unlike traditional materials like steel, FRP profiles are not susceptible to rust or corrosion, making them ideal for use in various automotive environments, including exposure to moisture, chemicals, and salt. Furthermore, FRP pultrusion profiles can be tailored to meet specific design requirements, allowing for flexibility in manufacturing. They can be produced in various shapes and sizes, offering versatility in designing complex components. This flexibility in design also allows for customization and optimization of vehicle performance. Lastly, FRP profiles offer good thermal and electrical insulation properties. This makes them suitable for applications where electrical conductivity needs to be minimized or thermal insulation is required. Overall, the lightweight, high strength, corrosion resistance, design flexibility, and insulation properties of FRP pultrusion profiles make them well-suited for use in the automotive manufacturing industry. They can contribute to the development of more efficient, safe, and durable vehicles.

Send your message to us

FRP Pultrusion Profiles - Lightweight and High Strength FRP Pultruded Gratings in Various Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 watt

- Supply Capability:

- 100000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords