Composite Pipes - High Strength Corrosion-Resistant Durable Professional Pultrusion FRP Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of FRP Process Pipe Description

1) Good physical mechanics performance

2) Being resistant to chemical erosion and longer service life

3) Excellent hydraulic characteristics

4) Lower installation and keeping cost

5) Flexible design and shorter reform term

6) No medium pollution

2. Main Features of FRP Process Pipe

1) Fiberglass Pultrusion Tubes

2) Good insulation performance

3) OEM is accepted

4) Small orders are accepted

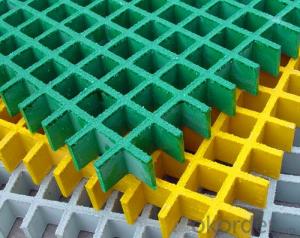

3. FRP Process Pipe Images

4. FRP Process Pipe Specification

1)Small specific gravity, light weight: FRP pipe’s specific gravity is 1.65-2.0 and one 1/4 compared with steel; hoop flexible tensile strength for FRP pipe is 150-420 MPa and axis tensile strength is 60-150MPa, similar to alloy steel. FRP pipe’s strength/specific gravity is 2 or 3 times compared with alloy steel so it can be designed according to customers different requirements for various pips bearing inside and outside pressure. For the same diameter pipe, FRP pipe’s weight is 1/2.5 compared with carbon steel pipe, 1/3.5 compared with cast iron pip, 1/8 compared with reinforced concrete pipe, so it’s easy for construction and transporting.

2) Fewer joints and efficient installment: Usual pipe’s length is 4-12 meters(other special length is also available according to customer demands). Single pipe is long with few joints to accelerate installment speed and reduce the fault possibility then improve efficiency of quality of construction of whole pipe.

5. FAQ of FRP Process Pipe

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing in FRP pipe products in China. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: What kind of material does glass steel ship honeycomb board use?

- The product adopts composite honeycomb structure, prefabricated glass fiber reinforced plastic panel, high strength glass fiber grid cloth and aluminum honeycomb core material, and is compounded by hot pressing. Because of the high strength of the grid cloth, the impact resistance and flexural strength of the composite board are very high.

- Q: FRP duct material plan is how to mention?

- Multi plan square, but also according to the combination of site and construction drawings, to see how much

- Q: Raw material and mix ratio of inorganic glass fibre reinforced plastic wind pipe

- In order to improve the quality of glass.Advanced technology may be used.The ratio seems to be 1 to 0.001. Pretty much within this range.

- Q: What kind of project needs fiberglass pipe?

- Glass fiber reinforced plastic material has the advantages of corrosion resistance, high strength, low weight, and other materials can not be compared, the use of a wide range of purposes, such as water supply, chemical raw materials, hot and hot water transportation, ventilation and so on

- Q: What kind of material is the pipe of the pipe that installs the pressure transmitter of GRP conduit? Is it fiberglass or carbon steel?

- This depends on what your medium is, the general food industry requires stainless steel, but the medium contains acidic substances, stainless steel is better than FRP corrosion resistance

- Q: Glass tube has different diameters with different prices. Who can elaborate?

- According to the standard requirements, DN25-DN2500 pipes can be produced. The pressure levels are gravity flow, 0.6MPa, 1.0MPa, 1.6MPa

- Q: Which is better, PVC pipe and GRP pipe?!

- To see the composition of your gas, fiberglass can be chosen according to the requirements of different resins for corrosion protection, and PVC for some gases are not corrosion-resistant,

- Q: What is the difference between glass tube, sand pipe and glass tube?

- The pipeline in the design according to the use of pressure, stiffness and other conditions to determine the need for sand, if the thickness of the pipe can satisfy the pressure requirements and can meet the requirement of stiffness, is generally not the sand.

- Q: Is it possible to touch the water when the glass fiber reinforced plastic pipe is polished?

- Because the resin curing mechanism of FRP products is resin, resin agent, resin curing agent together to react, and release a lot of heat, this process does not affect the curing process because of a small amount of water and at the same time, if you have a little bit of water molecules would because of the large amount of heat emitted by evaporate, so does not affect the bonding of glass and steel that will not affect the glass steel pipe interface

- Q: The role of glass fiber reinforced plastic cooling towers

- Is specializing in the production of glass steel cooling tower, cooling tower, cooling tower, commonly known as cooling tower, glass tower, tower, main square, round, crossflow and counterflow, no filler spray cooling tower series.

Send your message to us

Composite Pipes - High Strength Corrosion-Resistant Durable Professional Pultrusion FRP Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords