Fiberglass Tubes for FRP Membrane Housing - Special Customization for International Mainstream

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Brief Introduction of Membrane housings:

Product Introduction:

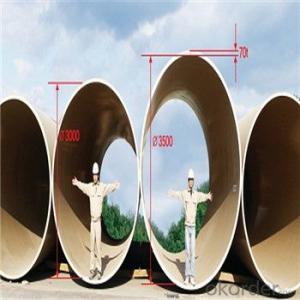

The FRP Membrane housing series products developed and produced by our company are suitable for the special customization of international mainstream RO, NF, UF, MF and other international standard membrane components as well as non-standard size membrane housing products. It is widely used in food industry, pharmaceutical and chemical industry, electronic power, metallurgy and petrochemical, reclaimed water reuse, seawater desalination and other water treatment projects.

Product Feature:

Physical Properties:

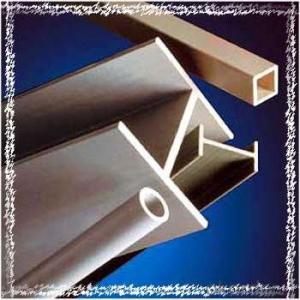

a. Advanced molding process is adopted to improve the finish of inner wall of the product.

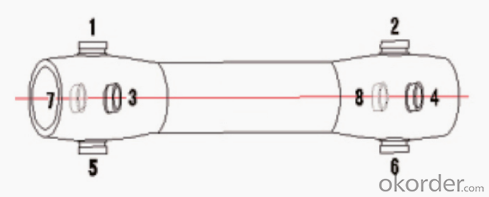

b.Multiport are available according to customer's requirement and easy installation to ensure the product is more flexibility in the system.

c.E-Glass fiberglass is selected as reinforced material to improve the compression resistance, fatigue resistance and deformation resistance of the products.

d.The embedded ring ensures that the fibrous tissue of the housing cannot be damaged mechanically, and improves the smoothness and convenience of the installation of end assembly.

e. LZRO/BALANCE series of products adopt high grade automobile baking varnish craft to ensure the smoothness and brightness of the product surface.

Chemical Properties:

a.Adopt epoxy resin system, which has excellent corrosion resistance, anti-aging property, high temperature resistance, and oxidation resistance of the products.

b.The advanced technology ensures the stability of products.

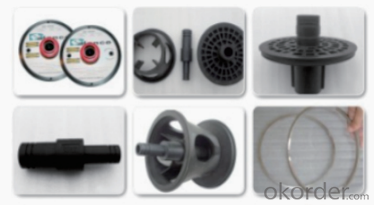

Spare Parts of The Membrane Housing

1) Technology

a.The bearing plate adopts aerial processing craft which efficiently improves the intensity and capacity to resist deformation.

b.Seal kit adopts special structure and technique which efficiently enhances the leak tightness, anti-aging and simple assembly and dis-assembly.

c.The three-turning locking ring which is designed according to the human body mechanics for easyinstallation and removing.

2)Materials

a.Bearing plate is made of aluminum alloy to enhance the intensity and improve the feature of resisting deformation.

b.Sealing elements adopt environmental-friendly material to assure the tightness and high water quality, as well as to improve its anti-aging capacity.

c.Feed /concentrate port adopt SS316L with high quality to assure outstanding anti-corrosion property and convenient maintenance.

d.Provide professional choice of material for special industries.

Quality Assurance:

1)Blasting test with 6 times design pressure.

2)More than 100,000 times of fatigue test.

3)100%qualified products tested by hydraulic test which is 0.4-1.2 times four levels of low pressure and high pressure.

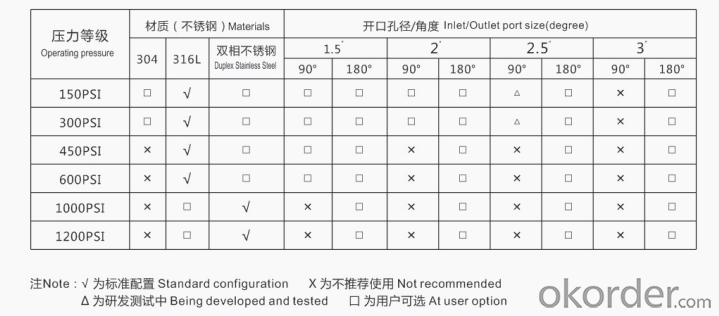

Inlet/Outlet Port Options:

Size and location options of inlet and outlet of Lianzhong products: 1.5 "(standard configuration), 2", 2.5* and 3 *. Standard configuration is 2 pcs of 0" horizontal side ports. Multiple ports are optional also. Customers can customize different opening sizes according to their requirements.

Note: Each end can provide a maximum of 4 side openings, and the angle of side opening is 180° for the port bigger than 2".

Material and Size of Inlet/Outlet Water Nozzles:

Thread Type Options of Water Outlet:

GB/NPT/other standards

The thread can be customized to international standard according to customer's requirement.

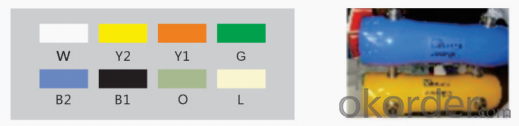

Paint Color Options:

Zhongfu Lianzhong provides the following colors for customers to choose.:

White is the standard color of the products of Zhongfu Lianzhong, and other colors are value-added services (O is the primary color, L is the LOGO color).

According to the customer's own color ( logo color ) for production, to help customers establish their brand image. Primary color products can be provided also.

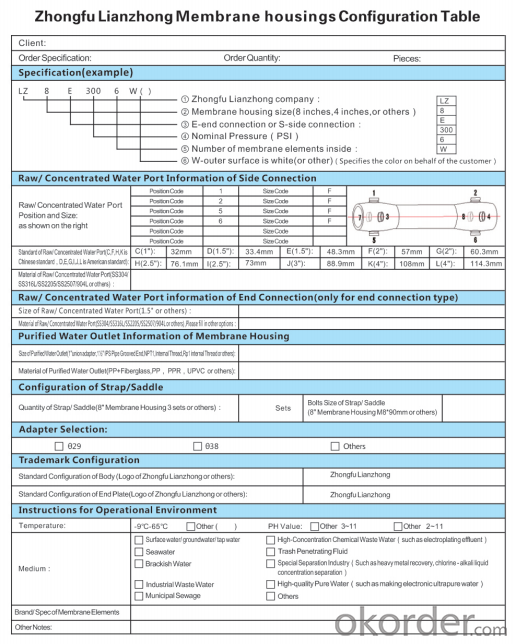

Ordering Instruction:

300PSI standard products are available in stock. In addition to producing membrane housing products of international standard and general specifications,we can also customize non-standard Membrane housings with diameters of 6 inches, 10 inches, 12 inches and less than 20 inches according to customers' requirements. Please consult the sales department of our company for specific product design and manufacturing.

Quality Control

A number of industry senior experts are responsible for the production , management ,technology and R&D of Lianzhong Membrane housings , and strictly in accordance with the ISO9001: 2015 management system. We have established a scientific quality assurance system, and own complete testing equipment.we implement three-level inspection system.

According to ASME standard, the pressure cycle failure test of FRP Membrane housing was carried out to verify the mechanical properties and fatigue life of FRP Membrane housing.

Quality Commitment:

1) 100% products pass 1.2 times water pressure test.

2) 100,000 times design pressure fatigue test.

3) Blasting test with 6 times design pressure.

100% products have their own unique code, easy to track product quality.

- Q: Do we need glue for silicone rubber fiber sleeving production?

- Production of high purity glass fiber tube made of alkali free, then in the management of wall surface coating adhesive CL-24 heat vulcanization glue, the high temperature resistant silicone coating material in heating and vulcanizing machine in heating vulcanization molding.

- Q: Why is it forbidden to use polyvinyl chloride fibre glass pipes as wire conduits and buried in the floor?

- PVC20 pipes are usually used. If you wear two wires, use 16. You need a bow, a few lines, and a 20 spring, you can bend it to 90 degrees.

- Q: PPR antibacterial pipe and glass fiber pipe for home decoration

- PPR joined in the inner tube of antibacterial silver series inorganic antibacterial layer, due to the bacterial surface with a negative charge, so the silver ions with positive charge was adsorbed on the surface of bacteria, and destroy the electrolytic balance, leading to bacterial death damage.

- Q: How about the whole PPR fiberglass tube? How about the home?

- Glass fiber PPR PPR is different with ordinary glass fiber PPR middle layer is a glass tube component, inside and outside layer is a composite of high quality PPR, between the layers by hot melt adhesive bonding, set of glass fiber and pure plastic pipe merits.soon, with temperature and pressure resistant performance, small heat expansion coefficient, vibration resist oxygen significantly the characteristics, suitable for high temperature hot water, and PPR plastic pipe performance than fiberglass PPR slightly inferior point.

- Q: How to separate the glass fiber FR-PPR and reinforce the composite tube?

- The simplest way is to use fire, and after burning about 30% of the residue should be glass fiber pipe.

- Q: What material is the glass pipe?

- Because of the different kinds of resins used, they are called polyester glass fiber reinforced plastics, epoxy glass fiber reinforced plastics and phenolic resin glass fiber reinforced plastics. It has the characteristics of light and hard, non conductive, high mechanical strength, anti-aging, high temperature resistance, corrosion resistance and so on.

- Q: Glass fiber pipe to be set on a product, I feel large dust, and wearing a mask, I do not know

- Just reduce the amount of inhalation, effective, but can not put an end to dust inhalation

- Q: PP-R what is the pressure of the heat pipe?

- PPR pipe has GB and non GB, there are specific tubes, glass fiber tubes, aluminum tubes and other steady state, under pressure generally in the outer layer of the pipe are marked, there is no general do not use it

- Q: The role of glass fiber tubing

- No alkali glass fiber itself has a strong tensile force, will not wrinkle, break, vulcanizing, smokeless, halogen free, non-toxic

- Q: What does fiberglass reinforced composite PPR pipe mean?

- Wang Yue fiber reinforced PP-R composite tube using high quality imported atactic polypropylene and glass fiber reinforced composite material, its anti swelling, compressive strength, wear resistance and other properties than common PP-R pipe, the same installation convenient, more superior performance. At present, it has been widely used in heat supply network, HVAC systems, solar energy systems and water supply and drainage systems, and other types of fluid transportation.

Send your message to us

Fiberglass Tubes for FRP Membrane Housing - Special Customization for International Mainstream

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Lianyungang Zhongfu Lianzhong Composites Group Co.,Ltd.

Lianyungang Zhongfu Lianzhong Composites Group Co.,Ltd.