Composite Fiberglass Reinforced Plastic (FRP/GRP) Pipes for Seawater Desalination Projects

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Pipe Description

Made from the high quality corrosion resistant resin and continuous fiber winding without alkali, filament winding FRP pipe possesses the characteristics of lightness, high strength, distinguished corrosion resistance and expedient installation and maintenance etc.,

FRP Pipes were applied widely in the oil-field system of sewage treatment, electrical plant water circulation, water pipe with electric magma and projects of chemical engineering, metallurgy, and medicine processing etc.

our company (headquarter in Jiangsu Province) has been the No. 1 in exporting composites products domestically, annual capability of 100,000 tons for pipes & tanks as well as 10,000 pieces of wind turbine blade, with branches in Thuringia of Germany, Liaoning province, Neimenggu Province, Gansu Province, Xinjiang Province and Sichuan Province etc.

We are the exclusive FRP manufacturer with rich experiences in cooperating with foreign companies worldwide, the only supplier that provides large-diameter FRP pipes to the nuclear power station. Sole company owning finite element analysis in China. 20 production lines are in good operation.

Main Features of the FRP Pipe

Corrosion-resistant

Light weight

Long standard lengths

Extremely smooth bore

Precision sealability

Flexible manufacturing

High technology pipe design

High technology pipe manufacturing system producing pipe that complies to stringent performance standards (AWWA, ASTM, DIN, EN,BS, etc.)

FRP Pipe Application

1)drinking water transmiting

2)sewage pipeline,rainwater pipelin

3)angricultural irrigation

4)seawater desalination system

5) other kinds of liquid transmiting

6)municipal engineering construction

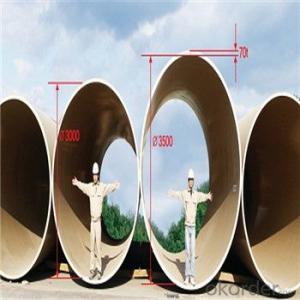

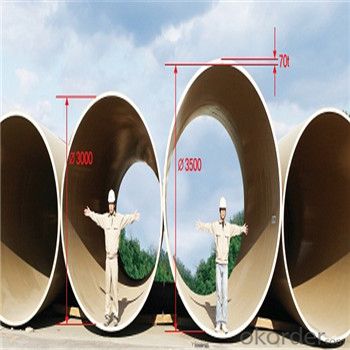

FRP Pipe Images

FRP Pipe Specification

Diameter: DN300-4000

Pressure:PN6-25

Standard length: 6m, 12m

Execute standard:JC552,ASTMD2996

Management System & Certificates

Management system: ISO9001, ISO14001, OHSAS18001,

Performance standards: ASTM D3262, D3517, D3754/AWWA C950, M-54/China Standard B/21238, JC552, CECS190, CECS129; DIN16868/ BS 5480;

WRAS Certificate, API Certificate, Installation Qualification.

Caesar II is applied for stress analyzing of piping system, AFT impulse is used for analysis of water hammer. Meanwhile we can supply finite element analysis to the customer.

FAQ of FRP Pipe

Q: What is fiberglass composite?

A: Fiberglass composite is a laminate made from glass fibers or filaments and thermosetting resin. It is commonly known as RTRP, RTMP, FRP, GRP, GRE and GRV.

Q: Are fiberglass pipes fragile?

A: Due to the elastic nature of the resin which holds the clothlike glass fibers together, fiberglass is strong and flexible. FPI products meet the rigorous "Impact Test" requirements of the international standard e.g. BS, API, ...

Q: What is the trade information

A: Trade terms:FOB,CIF,EXW

Payment terms:T/T,L/C

Shipping:By sea,by air and by express delivery

- Q: Raw material and mix ratio of inorganic glass fibre reinforced plastic wind pipe

- In order to improve the quality of glass.Advanced technology may be used.The ratio seems to be 1 to 0.001. Pretty much within this range.

- Q: What can be done to solve the leakage of FRP pipe?

- The method of mending is hand paste. The stones must be taken away so that the pipes are restored to their original shape. If you can get into the pipe, polish it first and repair the lining.

- Q: Galvanized steel sheet and inorganic glass fibre reinforced plastic pipe are calculated according to this norm or norm

- According to the project of quota valuation mode, input the actual quantity according to the quota item number, the following materials will automatically adjust the quota quota project, has been considering material wastage, when engineering calculation does not need additional.

- Q: What's the process of continuous winding glass fiber reinforced plastic sand pipe?

- On line inspection: the pipe being cut and grinded is delivered to the water pressure test machine through the conveyor. After the test is qualified, the pipe joint which has been tested by hydraulic pressure is sent to the pipe joint installation machine for joint installation.

- Q: What is fiberglass communication tube?

- The appearance of glass fiber reinforced plastic communication tube is to make full use of the high strength, impact resistance and corrosion resistance of glass fiber reinforced plastic, so as to ensure the safety of the optical cable or cable in the pipe hole under the action of sudden outside force. However, the process of making glass steel pipes will cause some defects of FRP pipe in communication field, because there are a lot of glass tube or end of steel fiber in irregular stands, glass fiber of these irregular stands can pierce the cable protective rubber layer in the cable laying process, once exposed to in the optical fiber cable, will inevitably lead to deflection of light signal transmission, which seriously affects the quality of signal transmission, which is fatal to the communication network. The problem is solved by the steel tube off the glass.

- Q: Are there any differences between FRP pipes and FRP pipes?

- The mechanism glass magnesium composite pipe is made of glass cloth, magnesium and earth, which is hard to burn. The glass fiber reinforced plastic pipe is made of glass cloth and resin, and it is inflammable and light in weight.

- Q: Glass fiber reinforced plastic pipeline to do anti-corrosion?

- Glass fiber reinforced plastic itself belongs to a kind of anticorrosive material, and usually needs no antiseptic treatment. However, mainly depends on the environment and requirements.

- Q: Slurry circulation glass fiber reinforced plastic pipe

- Slurry circulation glass fiber reinforced plastic pipeline has good corrosion resistance. FRP pipes are resistant to acid, alkaline, and non fluid erosion. In general, the service life of the steel pipe is 15 years, the cast iron pipe is 5 - 10 years, and the glass tube can be used for 50 years.

- Q: What are the posts of glass fiber reinforced plastic sand pipe and the corresponding occupational hazards and protection?

- FRP material has the characteristics of excellent corrosion resistance, no underground water or sewage pipe tube with acidic or alkaline causes no damage to the use of the product, and the product itself, do not need to do any protective measures, steel pipe and concrete pipe does not have the advantage.

- Q: A basic overview of FRP pipes

- FRP pipes are made of resin (feed water, food grade resin), glass fiber and quartz sand as raw materials and made by special process.

Send your message to us

Composite Fiberglass Reinforced Plastic (FRP/GRP) Pipes for Seawater Desalination Projects

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords