Polyethylene Composite FRP/GRP Pipe for Oil & Offshore Fields

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Pipe Description

Made from the high quality corrosion resistant resin and continuous fiber winding without alkali, filament winding FRP pipe possesses the characteristics of lightness, high strength, distinguished corrosion resistance and expedient installation and maintenance etc.,

FRP Pipes were applied widely in the oil-field system of sewage treatment, electrical plant water circulation, water pipe with electric magma and projects of chemical engineering, metallurgy, and medicine processing etc.

This FRP pipe has been tested and well-operated till now in the oil-field of Zhongyuan, Shengli, Daqing, Jianghan and Liaohe long distance conveying pipeline and the system of sewage treatment and Tibet Yangbajing Electrical Plant, Pakistan Feisalamade & Keteli Electrical Plant and Qinshan Nuclear Power Station, and therefore enjoyed the applause of the customers.

Main Features of the FRP Pipe

Corrosion-resistant

Light weight

Long standard lengths

Extremely smooth bore

Precision sealability

Flexible manufacturing

High technology pipe design

High technology pipe manufacturing system producing pipe that

complies to stringent performance standards (AWWA, ASTM, DIN, EN,BS, etc.)

FRP Pipe Application

1)drinking water transmiting

2)sewage pipeline,rainwater pipelin

3)angricultural irrigation

4)seawater desalination system

5) other kinds of liquid transmiting

6)municipal engineering construction

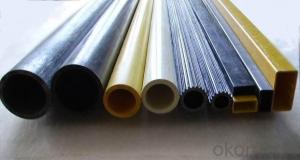

FRP Pipe Images

FRP Pipe Specification

Diameter: DN300-4000

Pressure:PN6-25

Standard length: 6m, 12m

Execute standard:JC552,ASTMD2996

Our Customers & Projects (Part)

We have established cooperation relationship with customers from over 160 countries, and work closely with Alston, Outotec OYJ, HYUNDAI, Samsung C&T Engineering & Construction, Fuji Heavy Industries, Hyflux Ltd, Sinopec, Petrochina, Shell etc,and are keen to cooperate with you as well.

FAQ of FRP Pipe

Q: What is fiberglass composite?

A: Fiberglass composite is a laminate made from glass fibers or filaments and thermosetting resin. It is commonly known as RTRP, RTMP, FRP, GRP, GRE and GRV.

Q: Are fiberglass pipes fragile?

A: Due to the elastic nature of the resin which holds the clothlike glass fibers together, fiberglass is strong and flexible. FPI products meet the rigorous "Impact Test" requirements of the international standard e.g. BS, API, ...

Q: What is the trade information

A: Trade terms:FOB,CIF,EXW

Payment terms:T/T,L/C

Shipping:By sea,by air and by express delivery

- Q: Do I need CCC certification for ventilated GRP?

- Usually fiberglass, air conditioning, ventilation pipes will have insulation requirements, the general need not heat preservation.

- Q: What kind of material is the pipe of the pipe that installs the pressure transmitter of GRP conduit? Is it fiberglass or carbon steel?

- It is generally assumed that it is made of glass fiber reinforced plastic. The main pipe is made of glass fiber reinforced plastic. The medium is corrosive. Other materials must not be suitable

- Q: Is there any ventilation duct made of glass fibre reinforced plastic in Baotou?

- 1. Corrosion resistant FRP pipes resist acid, alkali, salt, sea water, untreated sewage, corrosive soil or groundwater, and the corrosion of numerous chemical fluids.2, good frost resistance FRP heat pipe temperature range between 40 to 80 DEG C, if the first with a special resin use temperature can reach higher.

- Q: How is FRP ventilation pipe made?

- Solidification strippingThe coated FRP pipe can be released after a period of constant pressure to a certain strength. When the mold is released, the pre - prepared ejection support points shall be removed to separate the mold from the molded air pipe and then to exit the mold. Finally, remove the glass paper on the inside and outside surface. Air duct after stripping. Excess parts or burrs can be polished by hand cutting machine or sand grinder.

- Q: How to repair and repair the broken hole of GRE glass fiber reinforced plastic pipe?

- Place an iron or glass piece of steel on a broken hole like a bicycle tire, then use three oil, two cloth, or five oil three cloth;

- Q: How is the glass reinforced septic tank and the cement drain pipe connected?

- Very simple, ah, first install the septic tank, and then drain the pipe ah!

- Q: What's the price of fiberglass reinforced sand pipes?

- It must be different. It costs a lot of freight, so I suggest buying it locally. Henan is in Henan.

- Q: How many times can the temperature withstand of FRP winding pipes? What are the factors?!

- The temperature of FRP winding pipe is greater than -70 degrees Celsius, less than 250 degrees celsius.

- Q: Can FRP pipes be used in heating pipes?

- FRP pipes are generally not used in heating pipes, because the use temperature of FRP pipes is limited, as detailed below:1. universal unsaturated polyester FRP can only be used for less than or equal to 60 degrees (HG/T20696-1999)2. bisphenol A unsaturated polyester FRP can only be used for less than or equal to 100 degrees HG/T20696-1999)3. vinyl unsaturated polyester glass fiber can only be used for less than or equal to 120 degrees HG/T20696-1999)4. epoxy FRP can be used for less than or equal to 90 degrees HG/T20696-1999)5. glass fiber reinforced plastic sand holding pipes can only be used for less than or equal to 50 degrees (GB/T21238-2007)

- Q: What is the elastic modulus of glass fiber reinforced plastic?

- Glass fiber reinforced plastic is another name for glass fiber reinforced plastics, commonly known as FRP (Fiber Reinforced Plastics), that is, fiber reinforced composite plastic. Depending on the fiber used, glass fiber reinforced plastics (GFRP), carbon fiber reinforced plastic (CFRP), boron fiber reinforced composite plastics and so on are classified. It is a kind of composite material made of glass fiber and its products (glass cloth, band, felt, yarn, etc.) as reinforcing material and synthetic resin as base material. Fiber reinforced composites are composed of reinforced fibers and matrix. Fiber (or whisker) diameter is very small, generally below 10 mu m, less defects and smaller, fracture strain of about 30/1000, is brittle material, easy to damage, fracture and corrosion. The matrix is much lower in strength and modulus than fiber, but it can withstand large strains, often with viscoelasticity and elasticity, and is a ductile material.

Send your message to us

Polyethylene Composite FRP/GRP Pipe for Oil & Offshore Fields

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords