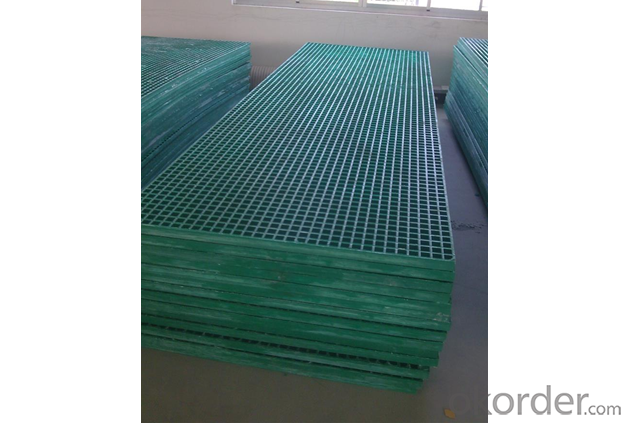

FRP Pultrusion Profiles - FRP Gratings, Molded Gratings, and Modern Shape Fiberglass Plastic Walkway Grating

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

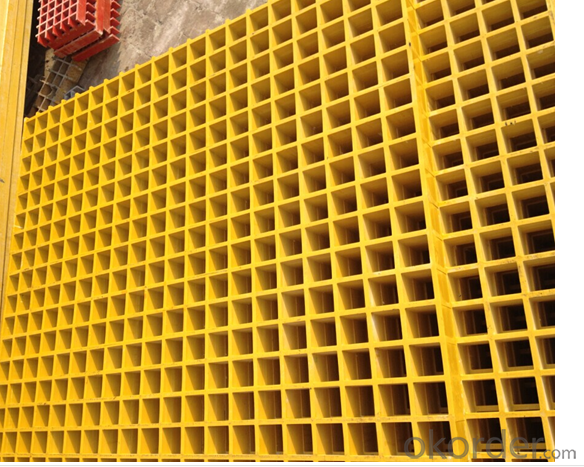

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

- Electrical Insulating

Aging Resistance

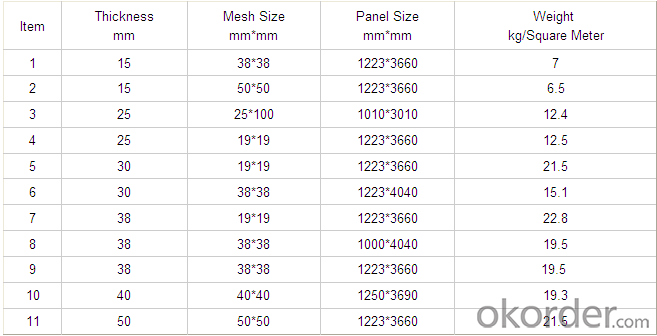

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

- easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

- Pool railings in sewage treatment industry

Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

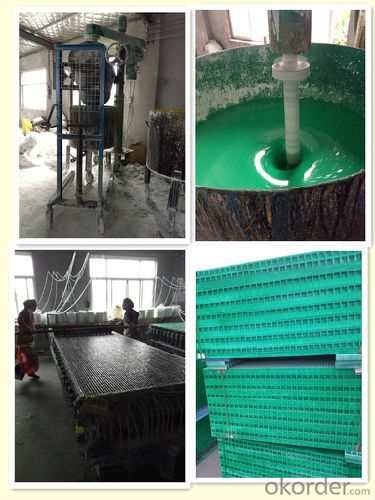

PROCESS

FACTORY

- Q: Can FRP pultrusion profiles be used for structural applications?

- Certainly, FRP pultrusion profiles can be utilized for structural purposes. The process of pultrusion involves pulling fiber reinforcements through a resin bath and a heated die to cure the resin, resulting in robust, lightweight, and corrosion-resistant profiles with exceptional mechanical properties. The high strength-to-weight ratio of FRP pultrusion profiles makes them widely employed in different structural applications. These profiles can be engineered to possess specific load-bearing capacities, stiffness, and durability, making them suitable for a wide range of structural requirements. FRP pultrusion profiles find common use in various structural applications such as bridges, walkways, platforms, handrails, supports, beams, columns, and reinforcements in concrete structures. They are particularly advantageous in situations where traditional materials like steel or wood are unsuitable due to concerns regarding corrosion, electrical conductivity, or weight. The benefits of FRP pultrusion profiles are numerous. They are lightweight, making them easy to handle and transport. Furthermore, they exhibit resistance to corrosion, chemicals, and UV radiation, ensuring long-term durability even in harsh environments. Additionally, they possess excellent dimensional stability, remaining unaffected by warping, twisting, or shrinking over time. To summarize, FRP pultrusion profiles are highly suitable for structural applications owing to their strength, lightweight nature, corrosion resistance, and durability. They provide a cost-effective alternative to traditional materials while delivering superior performance in various structural projects.

- Q: What are the different shapes and sizes of FRP pultrusion profiles available?

- There is a wide selection of FRP pultrusion profiles, which come in various shapes and sizes, to accommodate different applications and industries. Some of the commonly found shapes are as follows: 1. Square and rectangular profiles: These profiles are utilized in construction, infrastructure, and industrial sectors, and they come in different dimensions. They possess exceptional structural strength and can serve as beams, columns, or other load-bearing components. 2. Round profiles: Round FRP pultrusion profiles are frequently employed as structural supports, handrails, and guardrails. They are available in different diameters to suit specific requirements. 3. I-beams: FRP I-beams are well-liked in the construction field because of their high strength-to-weight ratio. They are commonly used as structural members, supporting elements, or floor joists. 4. Channel profiles: Channel-shaped FRP profiles are utilized in applications that demand a combination of strength and versatility. They find use in cable trays, equipment supports, and framing systems. 5. Angle profiles: FRP angle profiles are commonly used as reinforcements or supports in construction and industrial settings. They provide stability and structural integrity to various components. 6. Custom profiles: In addition to the standard shapes mentioned above, FRP pultrusion profiles can be tailor-made to meet specific requirements. Manufacturers have the capability to create profiles with unique shapes and sizes that cater to the needs of different applications. It is worth noting that the availability of shapes and sizes may differ among manufacturers. Therefore, it is advisable to consult suppliers or manufacturers to determine the specific range of FRP pultrusion profiles they offer.

- Q: Can FRP pultrusion profiles be used in the automotive industry?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can definitely be used in the automotive industry. FRP pultrusion profiles offer several advantages that make them suitable for automotive applications. Firstly, FRP pultrusion profiles are lightweight, which is a crucial factor in the automotive industry as it helps in improving fuel efficiency and reducing overall vehicle weight. Lighter vehicles have lower energy consumption and emissions, making them more environmentally friendly. Secondly, FRP pultrusion profiles have excellent strength-to-weight ratio. This means they can provide high strength and stiffness while being lightweight. This property makes them ideal for structural components in automobiles, such as chassis, body panels, and support structures. Furthermore, FRP pultrusion profiles are highly corrosion-resistant, which is a significant advantage in automotive applications. Vehicles are often exposed to harsh environmental conditions, including moisture, salt, and chemicals. The corrosion resistance of FRP helps in ensuring the longevity and durability of automotive components, even in challenging environments. Additionally, FRP pultrusion profiles have good impact resistance, which is crucial for automotive safety. They can absorb and dissipate energy during impacts, reducing the risk of injury in case of accidents. Moreover, FRP pultrusion profiles can be customized and engineered to meet specific design requirements, allowing for versatility in automotive applications. They can be designed to have specific mechanical properties, shapes, and sizes, making them suitable for various automotive components. Overall, the lightweight, high strength, corrosion resistance, impact resistance, and customization options make FRP pultrusion profiles an excellent choice for the automotive industry. They offer numerous benefits, including improved fuel efficiency, enhanced safety, and prolonged component life, making them a viable alternative to traditional materials in automotive applications.

- Q: Can FRP pultrusion profiles be used in electrical or telecommunications applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in electrical or telecommunications applications. FRP pultrusion profiles are known for their excellent electrical insulating properties, high strength-to-weight ratio, and corrosion resistance. These characteristics make them suitable for various electrical and telecommunications applications. In electrical applications, FRP pultrusion profiles can be used as electrical insulators, cable trays, busbar supports, and electrical enclosures. They provide insulation and protection against electrical shocks and are often chosen as an alternative to traditional materials like metal or wood due to their non-conductive properties. Additionally, FRP pultrusion profiles are lightweight and easy to install, which further adds to their suitability in electrical applications. In telecommunications applications, FRP pultrusion profiles are used for cable management systems, antenna supports, and equipment enclosures. Similar to electrical applications, the non-conductive nature of FRP pultrusion profiles ensures the safety and reliability of the telecommunications infrastructure. The profiles can also be customized to meet specific design requirements, such as incorporating cable routing channels or mounting brackets for equipment. Furthermore, FRP pultrusion profiles offer excellent resistance to harsh environmental conditions, such as moisture, UV radiation, and chemicals. This makes them ideal for outdoor electrical or telecommunications installations, where exposure to these elements is common. Overall, FRP pultrusion profiles have proven to be a reliable and cost-effective choice for electrical and telecommunications applications, providing insulation, strength, durability, and resistance to environmental factors.

- Q: The difference between polyurethane pultruded profiles and glass reinforced plastic profiles

- The polyurethane pultrusion section is a product formed by mixing the polyol and a reactive isocyanate easily and quickly.Isocyanate is to optimize the molding characteristics and selection, these characteristics are: low viscosity (good impregnation fiber), gel time (easy to start and stop), rapid polymerization (improve molding speed), good surface finish, cost competitive.

- Q: Can FRP pultrusion profiles be customized or tailored to specific project requirements?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be customized or tailored to specific project requirements. Pultrusion is a manufacturing process that allows for the creation of continuous fiber-reinforced composite profiles with a high level of design flexibility. The specific requirements of a project, such as dimensions, shapes, and mechanical properties, can be accommodated by adjusting the design and manufacturing parameters. The customization process begins with understanding the project's needs and specifications. This includes determining the desired profile dimensions, cross-sectional shape, and mechanical properties such as strength, stiffness, and durability. Based on these requirements, engineers and manufacturers can develop a tailored solution. The customization of FRP pultrusion profiles can be achieved through various means. Firstly, the choice of reinforcement materials, such as fiberglass, carbon fiber, or aramid fiber, can be selected based on the desired mechanical characteristics. The orientation and volume fraction of the fibers can also be adjusted to optimize the strength and stiffness of the profile. Additionally, the resin matrix used in the pultrusion process can be customized to enhance specific properties, such as fire resistance, chemical resistance, or UV resistance. Various resin systems, including polyester, vinyl ester, or epoxy, can be utilized to meet the project's requirements. Furthermore, the pultrusion process allows for the incorporation of additional features during manufacturing. This includes adding inserts, fastener holes, grooves, or other structural details to the profile. These modifications can be tailored to the specific project requirements, ensuring compatibility with the overall design and assembly. Overall, FRP pultrusion profiles offer a high degree of customization and tailoring to meet specific project requirements. This versatility makes them a popular choice in various industries, including construction, infrastructure, aerospace, and automotive, where lightweight, durable, and corrosion-resistant materials are needed.

- Q: Are FRP pultrusion profiles resistant to electrical surges or lightning strikes?

- The composition of fiberglass reinforcement and resin matrix in FRP pultrusion profiles gives them inherent electrical insulation properties. This insulation serves as a defense against electrical surges and lightning strikes to a certain extent. Nevertheless, it is crucial to acknowledge that no material can provide absolute protection against extremely high voltage electrical surges or direct lightning strikes. In these instances, additional precautions, such as grounding and lightning protection systems, must be taken to ensure the safety of structures or equipment. Therefore, while FRP pultrusion profiles do offer some resistance to electrical surges and lightning strikes, it is strongly recommended to seek guidance from experts and adhere to relevant safety standards when designing and installing electrical systems in areas susceptible to such occurrences.

- Q: Are FRP pultrusion profiles resistant to moisture absorption?

- FRP pultrusion profiles possess remarkable resistance to moisture absorption, primarily due to the composition of the materials used in their construction. These profiles typically consist of a combination of fiberglass and resin, wherein fiberglass is naturally non-porous and impervious to moisture, while the resin is specifically designed to repel moisture. The moisture resistance of FRP profiles is further enhanced by the pultrusion manufacturing process. This process involves pulling the fiberglass and resin through a heated die, ensuring thorough impregnation of the fibers with resin and creating a dense and solid structure. Consequently, the resulting product exhibits exceptional resistance to water penetration and moisture absorption. Additionally, the moisture resistance of FRP pultrusion profiles can be augmented through the application of protective coatings or surface treatments, such as gel coats or UV-resistant finishes. These coatings provide an extra layer of defense against moisture ingress. The superior moisture resistance of FRP pultrusion profiles makes them an ideal choice for applications that involve exposure to water or high humidity, such as marine environments, wastewater treatment plants, or outdoor structures. By preventing issues like rot, rust, or degradation commonly associated with materials like wood or metal, these profiles offer a reliable and durable solution that can endure moisture exposure without compromising their structural integrity or performance.

- Q: Are FRP pultrusion profiles fire resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are fire resistant. The combination of the reinforcing fibers and the polymer matrix used in FRP pultrusion profiles provide them with excellent fire resistance properties. These profiles are manufactured using a process known as pultrusion, which involves impregnating reinforcing fibers such as fiberglass or carbon fiber with a thermosetting resin. This resin undergoes a curing process, resulting in a strong and durable composite material. One of the key advantages of FRP pultrusion profiles is their inherent fire resistance. The thermosetting resin used in the manufacturing process has properties that make it highly resistant to fire. When exposed to flames or high temperatures, the resin does not melt or burn easily, thus preventing the spread of fire. Additionally, the reinforcing fibers in FRP profiles also contribute to their fire resistance. Fiberglass, for example, is an inorganic material that does not burn. It acts as a barrier against heat transfer and helps to minimize the spread of flames. Furthermore, FRP pultrusion profiles can be engineered to meet specific fire safety standards and regulations. By incorporating additional fire retardant additives or using specialized resin systems, the fire resistance of these profiles can be further enhanced. It is important to note that while FRP pultrusion profiles are fire resistant, their exact fire rating may vary depending on the specific composition and design. Therefore, it is essential to consult with manufacturers or suppliers who can provide detailed information about the fire resistance properties of their FRP pultrusion profiles.

- Q: Can FRP pultrusion profiles be used in the construction of offshore platforms?

- Yes, FRP pultrusion profiles can be used in the construction of offshore platforms. FRP, or fiber-reinforced polymer, offers excellent corrosion resistance, high strength-to-weight ratio, and durability, making it suitable for the harsh marine environment. These profiles can be customized to meet the specific requirements of offshore platforms, providing structural support and stability while minimizing maintenance needs.

Send your message to us

FRP Pultrusion Profiles - FRP Gratings, Molded Gratings, and Modern Shape Fiberglass Plastic Walkway Grating

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords