FRP Pultrusion Profiles for Gratings - Superior Slip Resistance for Sewage Plant Paving

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

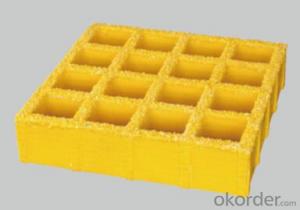

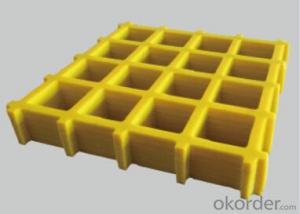

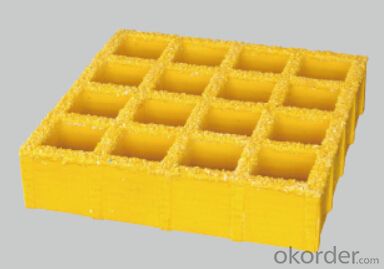

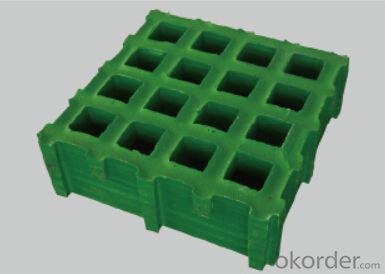

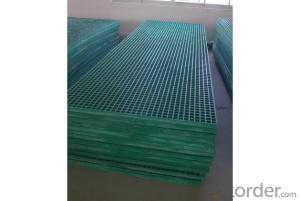

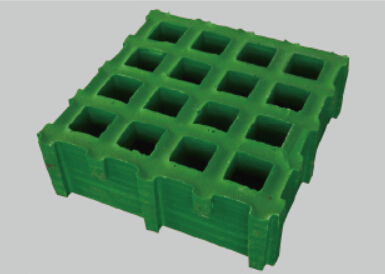

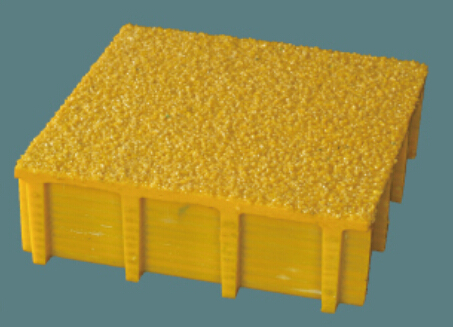

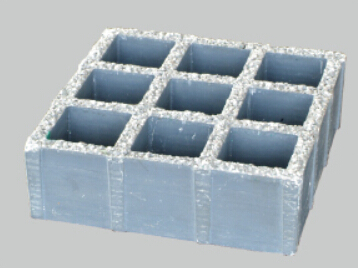

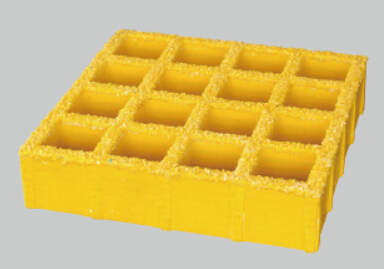

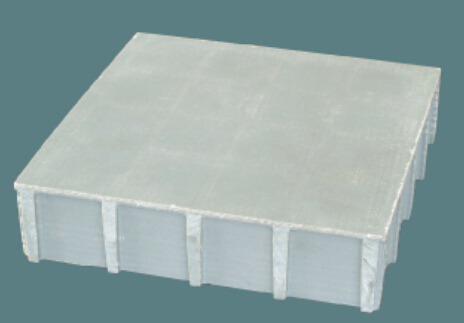

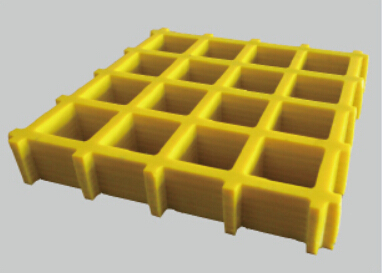

FRP molded grating made of vertical and horizontal continuous fiberglass fully soaked in unsaturated polyester resin giving perfect bi-directional mechanical properties. Combining unmatched corrosion resistance with strength, long life and safety, molded grating provide the ultimate in reliable performance, even in the most demanding corrosive conditions. Besides, it is easy to cut and install. CNBM offer the widest selection with panel sizes, colors and slip resistant surfaces, clients can avail FRP grating your specific requirements.

Product Features:

- Light but high loaded strength

- High anti-corrosion and anti-aging

- Easy installation and maintenance

- Low maintenance

- Non-conductive

- Lowest in life cycle cost

- Corrosion Resstance

- Anti-slippery

- Various sizes and color available

Colour Design:

To satisfy customer's design project, CNBM grating offers a wide selection of grating colors to choose from. The standard colors available for fiberglass grating as following:

- Blue

- Red

- Yellow

- Green

- Light Grey

- Dark Grey

Custom colors of fiberglass grating may be available upon request, you can contact us learn more.

- Q: Can FRP pultrusion profiles be used in the telecommunications and data communication industry?

- Indeed, the telecommunications and data communication industry can utilize FRP (Fiber Reinforced Plastic) pultrusion profiles. These profiles possess numerous advantages that render them appropriate for incorporation in this particular sector. First and foremost, FRP pultrusion profiles exhibit exceptional electrical insulation properties, rendering them perfect for applications in the telecommunications and data communication industry where minimizing electrical conductivity is imperative. FRP profiles do not conduct electricity, thereby ensuring the absence of interference or grounding issues that could potentially disrupt data transmission. Secondly, FRP pultrusion profiles are both lightweight and robust, resulting in a high strength-to-weight ratio. This characteristic makes them well-suited for the construction of communication towers, antenna supports, and satellite dish mountings. In these applications, the profiles must withstand environmental stresses such as wind loads. Moreover, FRP profiles exhibit outstanding corrosion resistance, a crucial attribute in the telecommunications and data communication industry where equipment is frequently exposed to harsh outdoor environments. Unlike traditional materials like steel or aluminum, FRP profiles do not rust or corrode, thereby guaranteeing the longevity and reliability of the infrastructure. Furthermore, FRP profiles can be easily customized and manufactured in various shapes and sizes to meet the precise requirements of telecommunications and data communication applications. This flexibility enables the design and construction of intricate structures capable of accommodating different equipment and technologies. In summary, FRP pultrusion profiles provide a multitude of advantages that render them highly suitable for application in the telecommunications and data communication industry. Their electrical insulation properties, lightweight yet strong nature, corrosion resistance, and design flexibility make them a dependable choice for supporting infrastructure in this sector.

- Q: Can FRP pultrusion profiles be used in agricultural applications?

- Yes, FRP pultrusion profiles can be used in agricultural applications. FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various agricultural applications. One common use of FRP pultrusion profiles in agriculture is in the construction of livestock enclosures such as fences, gates, and pens. These profiles offer excellent resistance to weathering, chemicals, and UV degradation, ensuring long-lasting performance in outdoor environments. Additionally, their lightweight nature makes them easy to handle and install. FRP pultrusion profiles are also used in the manufacturing of agricultural equipment and machinery. They can be utilized for structural components, such as beams and supports, as well as for functional parts like handles, brackets, and covers. The high strength of FRP profiles allows them to withstand heavy loads and harsh operating conditions, while their corrosion resistance ensures longevity in corrosive environments such as fertilizer storage areas or livestock waste management systems. Furthermore, FRP pultrusion profiles can be used for irrigation systems in agriculture. Their non-conductive nature makes them ideal for applications where electrical insulation is required, such as in the construction of irrigation pipes or channels. Additionally, the corrosion resistance of FRP profiles ensures that they can withstand exposure to water, chemicals, and fertilizers commonly used in agricultural irrigation. In summary, FRP pultrusion profiles are well-suited for agricultural applications due to their high strength, corrosion resistance, and durability. Whether it is for livestock enclosures, agricultural machinery, or irrigation systems, FRP profiles offer several advantages that make them a reliable choice in the agricultural industry.

- Q: Can FRP pultrusion profiles be used in the construction of theme park rides?

- Theme park rides can indeed incorporate FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess various advantages that make them suitable for this purpose. First and foremost, FRP pultrusion profiles possess a combination of lightness and strength, rendering them ideal for constructing ride structures that must endure dynamic loads and forces. Their remarkable strength-to-weight ratio enables the creation of intricate, sizable structures capable of supporting the weight of riders and withstanding the forces generated during operation. Moreover, FRP pultrusion profiles exhibit corrosion resistance, a crucial characteristic for theme park rides frequently exposed to outdoor environments, including moisture, chemicals, and UV radiation. This corrosion resistance ensures the durability and safety of the ride structures throughout their lifespan, reducing the need for costly maintenance and repairs. Another advantage of FRP pultrusion profiles lies in their design flexibility. They can be easily shaped and sized to meet the unique requirements of theme park ride designs. This versatility allows for the creation of distinctive, visually appealing ride structures that enhance the overall experience for park visitors. Furthermore, FRP pultrusion profiles possess excellent electrical insulation properties, particularly valuable for rides involving electrical components or systems. This insulation effectively minimizes the risk of electrical hazards, ensuring the safety of riders and operators. In conclusion, FRP pultrusion profiles are an excellent choice for constructing theme park rides due to their lightweight nature, high strength, corrosion resistance, design flexibility, and electrical insulation properties. By incorporating these profiles, safe, durable, and visually captivating ride structures can be developed, enhancing the enjoyment and excitement of theme park visitors.

- Q: Are FRP pultrusion profiles resistant to moisture or humidity?

- Yes, FRP pultrusion profiles are highly resistant to moisture and humidity. The combination of fiberglass reinforcement and resin matrix used in their construction makes them non-corrosive and impervious to water absorption. This inherent resistance ensures their durability and performance in humid or moist environments without compromising their structural integrity.

- Q: Are FRP pultrusion profiles fire resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are fire resistant. The combination of the reinforcing fibers and the polymer matrix used in FRP pultrusion profiles provide them with excellent fire resistance properties. These profiles are manufactured using a process known as pultrusion, which involves impregnating reinforcing fibers such as fiberglass or carbon fiber with a thermosetting resin. This resin undergoes a curing process, resulting in a strong and durable composite material. One of the key advantages of FRP pultrusion profiles is their inherent fire resistance. The thermosetting resin used in the manufacturing process has properties that make it highly resistant to fire. When exposed to flames or high temperatures, the resin does not melt or burn easily, thus preventing the spread of fire. Additionally, the reinforcing fibers in FRP profiles also contribute to their fire resistance. Fiberglass, for example, is an inorganic material that does not burn. It acts as a barrier against heat transfer and helps to minimize the spread of flames. Furthermore, FRP pultrusion profiles can be engineered to meet specific fire safety standards and regulations. By incorporating additional fire retardant additives or using specialized resin systems, the fire resistance of these profiles can be further enhanced. It is important to note that while FRP pultrusion profiles are fire resistant, their exact fire rating may vary depending on the specific composition and design. Therefore, it is essential to consult with manufacturers or suppliers who can provide detailed information about the fire resistance properties of their FRP pultrusion profiles.

- Q: Are FRP pultrusion profiles resistant to fungi and mold?

- FRP pultrusion profiles exhibit a general resistance to fungi and mold. This is attributed to the non-porous qualities of the construction materials, namely fiberglass and epoxy resins. These materials create an inhospitable environment for fungi and mold, thus establishing a high level of resistance against their proliferation and colonization. Moreover, FRP pultrusion profiles possess inherent moisture resistance, adding another deterrent to fungi and mold growth. In contrast to wood and its propensity to absorb moisture, FRP profiles do not retain water, rendering them highly resistant to these concerns. The combination of impermeable materials and moisture resistance make FRP pultrusion profiles an ideal choice for environments necessitating fungi and mold resistance, particularly those with high humidity or dampness. However, it is important to acknowledge that no material is entirely impervious to fungi and mold growth in all circumstances. In extreme conditions characterized by prolonged exposure to substantial levels of moisture and organic matter, there remains a possibility for some fungi and mold to colonize FRP profiles. Nevertheless, when compared to alternative materials, FRP pultrusion profiles offer a significantly superior level of resistance against these challenges.

- Q: Can FRP pultrusion profiles be used in cooling towers?

- Yes, FRP pultrusion profiles can indeed be used in cooling towers. FRP (Fiber Reinforced Polymer) pultrusion profiles offer excellent corrosion resistance, lightweight construction, and high strength, making them ideal for cooling tower applications. These profiles can withstand the harsh environmental conditions typically found in cooling towers, such as exposure to chemicals, moisture, and temperature variations. Additionally, FRP pultrusion profiles are easy to install, require minimal maintenance, and have a long service life, making them a cost-effective choice for cooling tower construction.

- Q: Are FRP pultrusion profiles non-conductive?

- Yes, FRP pultrusion profiles are non-conductive.

- Q: Can FRP pultrusion profiles be used in the construction of chemical processing equipment?

- FRP pultrusion profiles have the capability to be utilized in the construction of chemical processing equipment. These profiles possess multiple advantages that render them suitable for such applications. To begin with, FRP pultrusion profiles exhibit a high resistance to corrosion, making them an ideal choice for chemical environments where exposure to corrosive substances is frequent. Unlike conventional materials like steel, FRP pultrusion profiles do not rust or corrode, resulting in an extended service life and reduced maintenance costs. Moreover, FRP pultrusion profiles are both lightweight and strong, providing exceptional structural integrity and load-bearing capacity. This is particularly crucial in chemical processing equipment, where the materials employed must endure high pressures and temperatures. The strength of FRP pultrusion profiles permits the construction of sturdy and durable equipment. Furthermore, FRP pultrusion profiles offer flexibility in design, allowing for customization of shapes and sizes to fulfill specific requirements. This permits the construction of intricate chemical processing equipment with complex designs that are not easily achievable using traditional materials. Additionally, FRP pultrusion profiles possess excellent electrical insulation properties, which can be advantageous in chemical processing equipment where minimizing electrical conductivity is necessary to prevent unwanted reactions or hazards. In conclusion, FRP pultrusion profiles are a dependable and cost-effective option for constructing chemical processing equipment. Their corrosion resistance, strength, design flexibility, and electrical insulation properties make them suitable for a wide range of applications in the chemical industry.

- Q: Are FRP pultrusion profiles resistant to humidity or moisture?

- Yes, FRP pultrusion profiles are highly resistant to humidity or moisture due to their non-porous nature and the use of corrosion-resistant materials.

Send your message to us

FRP Pultrusion Profiles for Gratings - Superior Slip Resistance for Sewage Plant Paving

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords