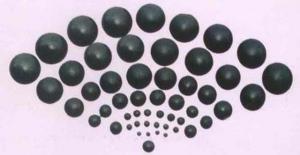

Forged Alloyed Steel Grinding Ball in Top Quality and Hardness apply for Mineral Processing and Refractory Factory

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

As one of the leading grinding balls specialists in China, we can certainly assist you in buying all kinds of grinding balls that suit your company needs. Our yearly production capacity in about 200000 Ton. We own an integrated set of advanced import production line, so that you can be satisfied with the quality of our products.

1. Hardness of Media Ball made by High Hardness and Top Quality Steel apply for Copper Mineral Industory and Power Plant

1A | 2A | 3A | 45 | 65 | |

Superficial | >60HRC | >60HRC | >60HRC | >58HRC | >60HRC |

Volumetric | >58HRC | >60HRC | >60HRC | >55HRC | >60HRC |

2.Feature of Media Ball made by High Hardness and Top Quality Steel apply for Copper Mineral Industory and Power Plant

1) In general, grinding steel ball has high hardness: surface hardness to 58-65 HRC, volume hardness of 56-65 HRC

2) impact toughness high: impact toughness more than 12 J / cm2.

3) broken rate is low: the actual broken rate is not higher than 0.5%.

4) loss of grinding forged steel ball round rate is low.

3.Chemical Composition of Media Ball made by High Hardness and Top Quality Steel apply for Copper Mineral Industory and Power Plant

Material | C | Mn | Si | Cr | S | P | |||

60Mn | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | 0.25max | 0.035max | 0.035max | |||

65Mn | 0.60-0.70 | 0.90-1.2 | 0.17-0.37 | 0.25max | 0.035max | 0.035max | |||

75MnCr | 0.70-0.85 | 0.70-0.85 | 0.17-0.37 | 0.40-0.60 | 0.030max | 0.030max | |||

Specification of Forged Steel Grinding Balls | |||||||||

Nominal diameter | Diametrical Tolerance | Weight of single ball in average | Surface hardness | Impact toughness | |||||

(mm) | (mm) | (g) | (HRC) | (j/cm2 ) | |||||

Φ20 | +2 -1 | 32 |

55-65 |

≥12 | |||||

Φ25 | 64 | ||||||||

Φ30 | 110 | ||||||||

Φ40 | 263 | ||||||||

Φ50 | 513 | ||||||||

Φ60 | +3 -2 | 888 | |||||||

Φ70 | 1410 | ||||||||

Φ80 | 2104 | ||||||||

Φ90 | 2996 | ||||||||

Φ100 | 4110 | ||||||||

Φ110 | +4 -2 | 5457 | 50-60 | ||||||

Φ120 | 7102 | ||||||||

Φ130 | 9030 | ||||||||

Φ140 | +4 -3 | 11278 | |||||||

Φ150 | 13871 | ||||||||

- Q: How to improve the surface roughness of casting parts?

- One is to improve the accuracy of the model; the two is to improve the molding sand mesh. How much is the other relationship?.

- Q: Casting parts need to be subjected to the kind of heat treatment after the weldment is finished

- This is difficult to say, the key is to see the specific parts and components, the final mechanical performance requirements.For example, gray cast iron, usually graphite annealing, to heat treatment annealing, surface quenching and so on, ductile iron can be a variety of annealing, normalizing, quenching and isothermal quenching, surface treatment, chemical treatment and so on, in a word, heat treatment of steel can usually, nodular cast iron can do. Malleable cast iron and vermicular cast iron are often subjected to graphitization annealing and stress relieving annealing, while wear-resistant cast irons often undergo quenching + low temperature tempering, and so on.Welding is the case, such as bearing steel welding must be quenched + low temperature tempering, machine spindle welding (repair welding) must be quenched and tempered treatment, and so on. Of course, if it is a general weld, there is no need for heat treatment or, at most, stress relieving annealing.

- Q: It is generally said that cast iron is re smelted by pig iron. My question is..:1 pig iron for melting iron, is directly cast into products (such as bed cover, etc.); or that is just the first pig iron smelting iron casting, such as to cover, bed and other products, will once again cast iron melt to casting?2, there are many castings to the engine. Are these castings made by the engine manufacturer themselves or bought by others?There is no need to answer all. Thank you!!!

- As a pig iron smelting, iron smelting belongs to physical, two belongs to the chemical refining, smelting, smelting generally not as a product after use, the product can be used as a chemical composition and casting the two refining, in general is to scrap as additional material after melting making products; engine castings have professional manufacturers making castings. You can own professional production of engine castings.

- Q: I often see Waixiejiagong drawings, casting, how to distinguish the latheman.

- Yes, casting drawings are casting drawings with machining allowances, slopes, and gating systems

- Q: What should I pay attention to when designing a casting structure?

- 1 of the casting in metal mold cooling was faster than sand, metal type and let, thus casting in metal mold casting, casting stress generated in the ratio of sand casting to crack tendency is also large, but also prone to misrun and cold lap, white (for casting casting). Defect. Usually: (1) in the prevention of metal casting casting crack aspect should pay attention to the following problems: the structure of A in wall thickness, wall transition and connection to the ease, corner fillet appropriate requirements such as should be more strict than sand casting; B should be connected vertically connected with the wall to tilt C; for the weak parts of the structure should be set to strengthen ribs, bosses, to prevent casting; D should minimize the obstacle free shrinkage of the boss, casting rib, flange and other prominent part; E in the casting arrangement of ribs, but also should consider its influence on the casting shrinkage.

- Q: What are the causes of pitting on the surface of a precision casting?

- The quality of the shell surface is out of order. Or shot blasting out of question.

- Q: What is the casting material?

- Kdl1588n said in detail, casting a lot of material, steel, iron, aluminum, copper, zinc, etc. can be, valuable, as well as gold and silver, the most common on cast steel and cast iron, cast aluminum and so on.

- Q: How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizingGenerally 0.06 mm or more

- Q: Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- Usually manual molding optional CT11 class, ordinary machine modeling optional CT10 class, high pressure molding should reach CT9 level. The tolerances on the wall thickness of the casting are comparable to those of other dimensions of the same casting.

- Q: In the design of casting steps and precautions, for casting design, we have what experience?.

- Two: the basic structure unit in the design of metal casting type and the parameters selected, usually should also pay attention to: (1) because of the metal type heat quickly, so the metal type casting minimum wall thickness should be bigger than the sand casting, metal type casting alloy minimum wall, different size of castings see table 1.1-31 thick can be selected; (2) the inner wall of the casting internal ribs and the thickness of wall thickness should be 0.6-0.7 connected, or as the inner wall (rib) cold slowly, cracks in the wall at the junction in the casting shrinkage;

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1983 |

| Annual Output Value | Above US$100 Million |

| Main Markets | South Asia, South Asia, Central America, Western Europe, Eastern Asia, Mid East, Oceania, Africa |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English;Chinese;Japanese;Korean |

| b) Factory Information | |

| Factory Size: | Above 20,000 square meters |

| No. of Production Lines | 8 |

| Contract Manufacturing | Grinding steel balls;Grinding steel cylpebs;Grinding media;Grinding meida ball |

| Product Price Range | Average |

Send your message to us

Forged Alloyed Steel Grinding Ball in Top Quality and Hardness apply for Mineral Processing and Refractory Factory

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords