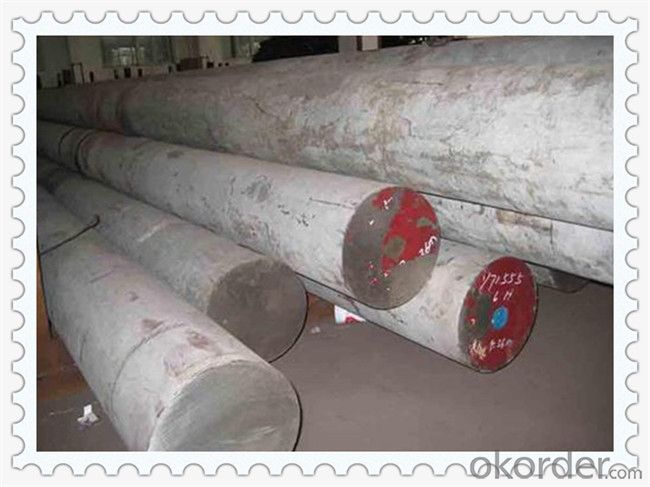

Forged Alloy Steel AISI 4140 Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description of AISI 4140 Round Bar

AISI 4140 round bar are flawless completely free from cracks and flakes, and does not contain any other imperfection,such as porosity non-metallic inclusions segregations, hard spots and residual tensions to a degree affecting their strength and durability.

| Product: | forged alloy steel AISI 4140 round bar |

| Material: | 4145, 42CrMo4, 4140, SAE8620 ,4340 etc. |

| Supplier Range: | OD.200-800mm,Weight≤20T |

| Delivery time: | 30 days after receive the deposit. |

| Produce Process: | EAF + LF + VD +(ESR) + Forged + Heat Treatment (optional) |

| Delivery condition: | Hot forged, Heat-treatment (Normalized / Annealed / Quenched / tempered), Rough machining. |

| Surface Finish: | Black, Peeled, Turned & Polished |

| Payment Term: | 30% advance by T\T; Balance pay before the shipment against shipping documents or irrevocable LC at sight |

| Technical Data: | Chemical Composition, Physical Properties and Mechanical Testing according to the customer's requirement and Standard. |

The steel is suited to applications where high surface pressures exist and friction is to be resisted as in the case of severely loaded gears, axles and pinions. It is used extensively in most industry sectors for applications requiring higher tensile strength.

Packing And Delivery

| Package | Seaworthy package (or as customer require) |

| MOQ | 1 Pieces |

| Delivery | 30 days (can be short if we have stock) |

| Payment | 30%T/T in advanced+70% balanced;irrevocable L/C at sight |

| Remarks | All-risk insurance and accept the third party test |

| Port | Tianjin/Qingdao/Shanghai |

Equipment

We are well-equipped with 2000-Ton Hydraulic press, 15-Ton Hydraulic manipulator, various kinds of Lathe and boring machine, product range OD 200mm-800mm, Length less than 9m.

- Q: How are steel round bars used in the manufacturing of fasteners and bolts?

- Steel round bars are used in the manufacturing of fasteners and bolts as they provide the necessary strength and durability required for these components. The bars are typically cut and shaped into the desired length and shape, and then undergo various processes such as threading or heat treatment to enhance their performance. The resulting steel rods are used as the main body of fasteners and bolts, providing the necessary structural integrity and reliability in various industrial applications.

- Q: What are the common alloying elements used in steel round bars?

- The common alloying elements used in steel round bars are carbon, manganese, silicon, and sometimes chromium, nickel, and molybdenum.

- Q: How do you calculate the length of a steel round bar?

- In order to determine the length of a steel round bar, it is necessary to measure its diameter and employ a basic formula that involves the diameter and the mathematical constant pi (π). To begin, utilize a caliper or measuring tape to measure the diameter of the steel round bar at its widest point. It is important to ensure an accurate outcome by measuring across the center of the bar. Once the diameter has been obtained, the circumference of the round bar can be calculated by multiplying the diameter by pi (π). The formula for calculating the circumference is: Circumference = π × Diameter Lastly, to ascertain the length of the round bar, one must either be aware of the number of complete rotations it makes or measure the distance it covers. If the number of rotations is known, multiply the circumference by the number of rotations. If measuring the distance covered, simply utilize the measured distance as the length of the round bar.

- Q: Can steel round bars be used for making fasteners?

- Yes, steel round bars can be used for making fasteners. They are commonly used in the manufacturing of bolts, screws, and other types of fasteners due to their strength, durability, and ease of machining. Steel round bars provide the necessary mechanical properties and can be threaded or shaped to meet specific fastening requirements.

- Q: What are the advantages of using sulfur-alloy steel round bars?

- Sulfur-alloy steel round bars offer several benefits. Firstly, they have superior machinability compared to other steel types. Adding sulfur to the alloy reduces friction between the tool and workpiece, resulting in smoother cutting and lower cutting forces. This simplifies and improves the efficiency of machining, saving time and reducing costs. Secondly, sulfur-alloy steel round bars possess excellent chip-breaking properties. The sulfur content encourages the formation of small, brittle sulfide inclusions within the steel, which act as effective chip breakers during machining. These inclusions break the chips into smaller pieces, preventing tangling and issues like built-up edges or poor surface finish. Another advantage is the improved surface finish of sulfur-alloy steel round bars. The sulfur content in the alloy minimizes the occurrence of built-up edges or burrs during machining. As a result, a smoother and more precise surface finish is achieved, which is particularly crucial for applications that require aesthetics or tight tolerances. Moreover, sulfur-alloy steel round bars exhibit good wear resistance. The sulfur content forms hard sulfide inclusions that enhance the hardness and wear resistance of the steel. This makes it suitable for applications subjected to abrasive wear, such as gear or bearing manufacturing. Lastly, sulfur-alloy steel round bars are frequently more cost-effective compared to other high-performance alloys. Adding sulfur is a relatively inexpensive process, making sulfur-alloy steel a more affordable option for many applications. This makes it an appealing choice for industries that require high-quality steel while considering costs. In conclusion, the benefits of using sulfur-alloy steel round bars include improved machinability, enhanced chip-breaking properties, better surface finish, good wear resistance, and cost-effectiveness. These advantages make sulfur-alloy steel round bars a popular choice in various industries, including automotive, aerospace, and manufacturing.

- Q: How are steel round bars used in the automotive industry?

- Steel round bars are commonly used in the automotive industry for a variety of applications due to their strength, durability, and versatility. One of the main uses of steel round bars in the automotive industry is for the production of crankshafts. Crankshafts play a crucial role in converting the reciprocating motion of the pistons into rotational motion, powering the vehicle. Steel round bars are ideal for this application as they offer high tensile strength, excellent fatigue resistance, and the ability to withstand high torque loads. Steel round bars are also used in the manufacturing of axles. Axles are responsible for transferring power from the engine to the wheels, supporting the weight of the vehicle, and providing stability. Steel round bars provide the necessary strength and rigidity required to handle the heavy loads and forces experienced by the axles. Additionally, steel round bars are utilized in the production of suspension components such as tie rods and sway bars. Tie rods are crucial for steering and maintaining proper alignment, while sway bars help to control body roll and improve handling. Steel round bars are preferred for these applications because they offer excellent torsional strength, allowing them to withstand the forces and stresses encountered during steering and suspension movements. Furthermore, steel round bars find use in the production of transmission shafts. Transmission shafts are responsible for transmitting power from the engine to the wheels via the gearbox. Steel round bars are well-suited for this application due to their high strength, resistance to bending, and ability to handle the rotational forces and torque generated by the engine. In summary, steel round bars are widely used in the automotive industry for various applications such as crankshafts, axles, suspension components, and transmission shafts. Their superior strength, durability, and versatility make them an ideal choice for these critical components, ensuring the safety, performance, and reliability of vehicles.

- Q: Can steel round bars be used in the renewable energy industry?

- Indeed, in the renewable energy industry, steel round bars find utility. Their versatility and durability render them fitting for diverse applications within renewable energy projects. As an illustration, they serve as support structures for solar panels, wind turbine towers, and hydroelectric power plants. The steel round bars furnish the requisite strength and stability to endure the adverse environmental conditions frequently encountered in renewable energy projects. Moreover, steel is a material highly amenable to recycling, thereby aligning with the sustainable principles upheld by the renewable energy industry. Consequently, steel round bars represent a feasible and frequently employed constituent in the construction and advancement of renewable energy infrastructure.

- Q: Can steel round bars be used for making agricultural equipment?

- Yes, steel round bars can be used for making agricultural equipment. Steel round bars are known for their high strength and durability, making them suitable for heavy-duty applications in the agricultural industry. They can be used to manufacture various agricultural equipment such as plows, tillers, cultivators, harrows, and seeders. The strength of steel round bars allows these equipment to withstand the harsh conditions in the field, including the impact of rocks and hard soil. Additionally, steel round bars can be easily shaped and welded, providing flexibility in designing and customizing agricultural equipment according to specific requirements. Overall, steel round bars are a reliable and cost-effective material choice for making agricultural equipment due to their strength, durability, and versatility.

- Q: Are steel round bars suitable for use in the automotive industry?

- Yes, steel round bars are commonly used in the automotive industry due to their strength, durability, and versatility. They are used in various applications such as axle shafts, drive shafts, suspension components, and engine parts. The high tensile strength and resistance to wear make steel round bars ideal for handling heavy loads and enduring demanding conditions in vehicles.

- Q: What are the different surface treatments for steel round bars?

- There are several different surface treatments available for steel round bars, including galvanizing, chrome plating, powder coating, and nitriding. These treatments are applied to enhance the corrosion resistance, durability, and appearance of the steel bars.

Send your message to us

Forged Alloy Steel AISI 4140 Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords