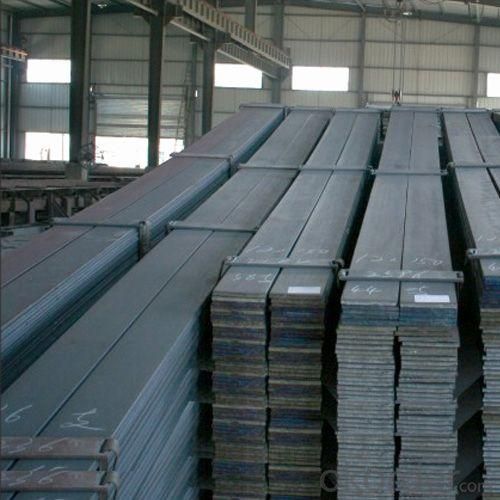

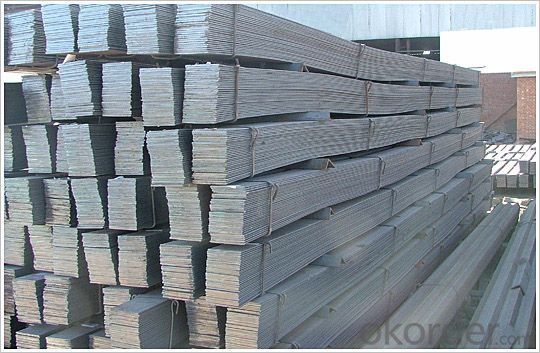

Flat Steel Bar Q235 SS400 A36 Ms Mild Hot Rolled Black Carbon

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Flat Steel Bar Q235 SS400 A36 Ms Mild Hot Rolled Black Carbon at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Flat Steel Bar Q235 SS400 A36 Ms Mild Hot Rolled Black Carbon are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Flat Steel Bar Q235 SS400 A36 Ms Mild Hot Rolled Black Carbon are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

carbon flat steel bar

1.Thickness:1.5mm-14mm

2.Width:10mm-1010mm

3.Grade:Q235, Q345, A36

4. BV verified

Details of carbon flat steel bar

| Name | carbon flat steel bar |

| Standard | AISI, ASTM, BS,DIN,GB,JIS |

| Grade | A36, SS400, Q235, Q345, S235,S275 |

| Dimensions | 1.5mm-14mm |

| Length | 6-12m |

| Technique | carbon flat steel bar |

| Tolerance | As the standard or as your requirement |

| Application | Metal structure, bridge, machiner, shipbuilding industry |

| Certificated | carbon flat steel bar |

| MOQ | 25 tons carbon flat steel bar |

| Delivery | Within 25 days after deposit |

| Payment | T/T or L/C |

Advantage carbon flat steel bar

1. Convenient in construction and save much time and labor

2. High mechanical strength

3. Low price, high quality

carbon flat steel bar specifications

| carbon flat steel bar | |||

Width (mm) | Thickness (mm) | Length (m) | Theoretical Weight (kg/m) |

| 20 | 2.0 | 6/9/12 | 0.31 |

| 20 | 2.5 | 6/9/12 | 0.39 |

| 20 | 2.75 | 6/9/12 | 0.43 |

| 25 | 2.5 | 6/9/12 | 0.49 |

| 25 | 3.75 | 6/9/12 | 0.74 |

| 30 | 2.5 | 6/9/12 | 0.59 |

| 30 | 3.5 | 6/9/12 | 0.82 |

| 30 | 9.75 | 6/9/12 | 2.30 |

| 40 | 3.5 | 6/9/12 | 1.10 |

| 40 | 4.75 | 6/9/12 | 1.50 |

| 40 | 11.75 | 6/9/12 | 3.69 |

| 50 | 2.75 | 6/9/12 | 1.08 |

| 50 | 4.5 | 6/9/12 | 1.77 |

| 50 | 9.75 | 6/9/12 | 3.83 |

| 60 | 5.5 | 6/9/12 | 2.60 |

| 60 | 7.5 | 6/9/12 | 3.53 |

| 60 | 11.5 | 6/9/12 | 5.42 |

| 80 | 5.5 | 6/9/12 | 3.45 |

| 80 | 7.5 | 6/9/12 | 4.71 |

| 80 | 11.75 | 6/9/12 | 7.38 |

| 100 | 3.25 | 6/9/12 | 2.55 |

| 100 | 4.75 | 6/9/12 | 3.73 |

| 100 | 7.5 | 6/9/12 | 5.89 |

| 120 | 9.75 | 6/9/12 | 9.18 |

| 120 | 11.75 | 6/9/12 | 11.07 |

| 150 | 9.75 | 6/9/12 | 11.48 |

| 150 | 11.5 | 6/9/12 | 13.54 |

| 150 | 13.5 | 6/9/12 | 15.90 |

| 160 | 11.75 | 6/9/12 | 14.76 |

| 200 | 9.5 | 6/9/12 | 14.92 |

| 250 | 5.75 | 6/9/12 | 11.28 |

| 340 | 7.75 | 6/9/12 | 20.68 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: Are steel flat bars suitable for marine or saltwater applications?

- Due to their vulnerability to corrosion, steel flat bars are generally unsuitable for use in marine or saltwater settings. When exposed to saltwater or other corrosive surroundings, steel flat bars can rapidly rust and degrade. This deterioration can jeopardize their structural strength, rendering them unfit for marine use where they would be consistently exposed to saltwater. To guarantee longevity and durability in saltwater applications, it is advisable to opt for materials explicitly engineered for marine environments, such as stainless steel or corrosion-resistant alloys.

- Q: Can steel flat bars be used for making stair treads or steps?

- Yes, steel flat bars can be used for making stair treads or steps. Steel is a strong and durable material that can provide stability and support for staircases. Flat bars can be easily fabricated and shaped to create treads or steps that are both functional and aesthetically pleasing. Additionally, steel's resistance to corrosion makes it suitable for outdoor or high-traffic areas where stairs are commonly found. However, it is important to consider the thickness and dimensions of the steel flat bars to ensure they can withstand the expected load and meet the necessary safety standards.

- Q: Can steel flat bars be used for creating handrails or guardrails?

- Yes, steel flat bars can be used for creating handrails or guardrails. Steel flat bars are commonly used in construction and fabrication due to their strength and durability. They can be easily shaped and welded to create custom handrails or guardrails that provide stability and safety in various settings such as staircases, balconies, or walkways.

- Q: Are steel flat bars available in different grades?

- Different grades of steel flat bars are available. These grades are determined by the chemical composition, mechanical properties, and intended use of the bars. Mild steel, carbon steel, stainless steel, and alloy steel are common examples of these grades. Each grade possesses distinct properties and characteristics that make them suitable for specific applications. When choosing the appropriate grade, factors like required strength, corrosion resistance, machinability, and weldability must be taken into consideration. The specific requirements of the project or application should be carefully considered in order to select the most suitable grade of steel flat bar.

- Q: What is 40x4 galvanized flat steel, please?

- The 40 represents the width of the flat steel (the length of the two sides of the flat bar), and the 4 represents the edge thickness of the flat steel (the width of the flat steel edge).

- Q: Can steel flat bars be used in the manufacturing of HVAC systems?

- Certainly! HVAC systems can utilize steel flat bars in their manufacturing process. Steel is widely employed in HVAC systems owing to its robustness, durability, and ability to withstand corrosion. The utilization of steel flat bars extends to numerous HVAC components, including brackets, supports, and frames. These bars offer stability and bolster the system, guaranteeing its optimal operation. Furthermore, steel flat bars can be easily tailored and fabricated to meet precise design specifications, rendering them suitable for diverse HVAC system configurations.

- Q: What is the surface area of flat steel 100*3 meters per metre?

- 2X (0.1x1+0.003x1+0.1x0.003) =0.2066 with a surface area of 0.2066 square meters.Flat, refers to the width 12-300mm, thickness 4-60mm, cross section is rectangular in shape and with a blunt edge of steel.

- Q: What industries commonly use steel flat bars?

- Steel flat bars are commonly used in a wide range of industries due to their versatile nature and durability. Some of the industries that commonly use steel flat bars include construction, manufacturing, automotive, infrastructure, and engineering. In the construction industry, steel flat bars are used for various purposes such as support beams, frames, braces, and structural components in buildings and bridges. They provide strength and stability to structures, making them ideal for withstanding heavy loads and pressure. Manufacturing industries also rely on steel flat bars for fabricating machinery, equipment, and tools. Due to their malleability, steel flat bars can be easily shaped and machined to meet specific requirements, making them suitable for various manufacturing processes. The automotive industry utilizes steel flat bars in the production of vehicles, especially in the chassis and body frames. Steel flat bars provide the necessary strength and rigidity to withstand the stresses and strains experienced by automobiles, ensuring safety and durability. Infrastructure projects such as highways, railways, and airports also extensively use steel flat bars. These bars are used in the construction of beams, columns, and other structural elements, providing the necessary strength to support heavy loads and withstand environmental conditions. Engineering industries also heavily rely on steel flat bars for a wide range of applications. These bars are commonly used in the fabrication of machinery, equipment, and components that require strength, resilience, and versatility. They are also used in the construction of support structures, frames, and braces required in various engineering projects. In summary, the industries that commonly use steel flat bars include construction, manufacturing, automotive, infrastructure, and engineering. Their versatility, strength, and durability make them indispensable in these industries for various applications and projects.

- Q: The difference between use and performance of hot rolled flat steel and longitudinally cut flat steel is discussed

- Its manufacturing process determines the poor dimensional accuracy of hot-rolled flat steel.Vertical shearing flat steel (fine shearing flat steel strip):The raw material board is produced by a larger factory, the raw material source is controllable, the material can be basically guaranteed, and the mechanical performance can basically meet the relevant GB standards.The dimension of vertical shear flat steel is relatively high.

- Q: Where can steel flat bars be purchased?

- There are several sources where one can purchase steel flat bars. These include hardware stores, home improvement centers, metal supply companies, and online retailers. Hardware stores like Home Depot and Lowe's typically have a variety of steel flat bars in different sizes and lengths. Home improvement centers such as Menards or Ace Hardware may also have steel flat bars available for purchase. Metal supply companies specialize in selling various types of metal, including steel flat bars, and usually offer a wide range of sizes and options for custom cutting. Additionally, there are numerous online retailers that sell steel flat bars, providing the convenience of shopping from home and often offering a larger selection and competitive prices. It is recommended to compare prices and quality before making a purchase, ensuring that the steel flat bars meet the required specifications and are sourced from reputable sellers.

Send your message to us

Flat Steel Bar Q235 SS400 A36 Ms Mild Hot Rolled Black Carbon

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords