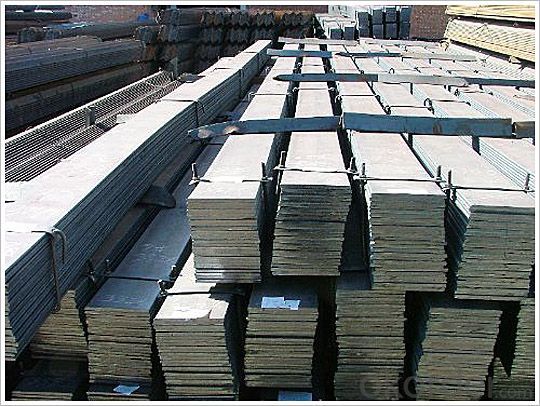

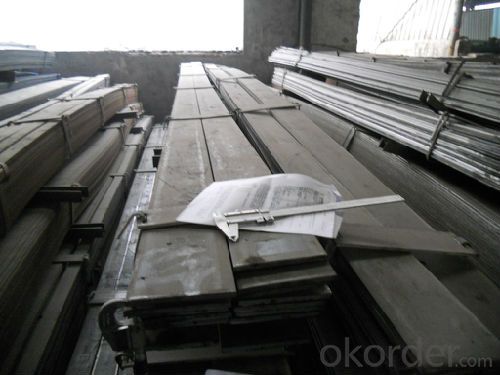

Flat Steel A36 Q235 SS400 Slit Ms Carbon Mild Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Flat Steel A36 Q235 SS400 Slit Ms Carbon Mild Hot Rolled at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Flat Steel A36 Q235 SS400 Slit Ms Carbon Mild Hot Rolled are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Flat Steel A36 Q235 SS400 Slit Ms Carbon Mild Hot Rolled are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Flat Steel

1.Thickness:1.5mm-14mm

2.Width:10mm-1010mm

3.Grade:Q235, Q345, A36

3.Factory producing, guaranteed material

| Flat Steel | |||

Width (mm) | Thickness (mm) | Length (m) | Theoretical Weight (kg/m) |

| 20 | 2.0 | 6/9/12 | 0.31 |

| 20 | 2.5 | 6/9/12 | 0.39 |

| 20 | 2.75 | 6/9/12 | 0.43 |

| 25 | 2.5 | 6/9/12 | 0.49 |

| 25 | 3.75 | 6/9/12 | 0.74 |

| 30 | 2.5 | 6/9/12 | 0.59 |

| 30 | 3.5 | 6/9/12 | 0.82 |

| 30 | 9.75 | 6/9/12 | 2.30 |

| 40 | 3.5 | 6/9/12 | 1.10 |

| 40 | 4.75 | 6/9/12 | 1.50 |

| 40 | 11.75 | 6/9/12 | 3.69 |

| 50 | 2.75 | 6/9/12 | 1.08 |

| 50 | 4.5 | 6/9/12 | 1.77 |

| 50 | 9.75 | 6/9/12 | 3.83 |

| 60 | 5.5 | 6/9/12 | 2.60 |

| 60 | 7.5 | 6/9/12 | 3.53 |

| 60 | 11.5 | 6/9/12 | 5.42 |

| 80 | 5.5 | 6/9/12 | 3.45 |

| 80 | 7.5 | 6/9/12 | 4.71 |

| 80 | 11.75 | 6/9/12 | 7.38 |

| 100 | 3.25 | 6/9/12 | 2.55 |

| 100 | 4.75 | 6/9/12 | 3.73 |

| 100 | 7.5 | 6/9/12 | 5.89 |

| 120 | 9.75 | 6/9/12 | 9.18 |

| 120 | 11.75 | 6/9/12 | 11.07 |

| 150 | 9.75 | 6/9/12 | 11.48 |

| 150 | 11.5 | 6/9/12 | 13.54 |

| 150 | 13.5 | 6/9/12 | 15.90 |

| 160 | 11.75 | 6/9/12 | 14.76 |

| 200 | 9.5 | 6/9/12 | 14.92 |

| 250 | 5.75 | 6/9/12 | 11.28 |

| 340 | 7.75 | 6/9/12 | 20.68 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: What is the tolerance for thickness in steel flat bars?

- The tolerance for thickness in steel flat bars can vary depending on the specific industry standards and requirements. Generally, the tolerance for thickness in steel flat bars is typically specified in terms of a plus or minus value. For example, a common tolerance for thickness in steel flat bars could be +/- 0.005 inches. This means that the actual thickness of the steel flat bar can deviate from the specified thickness by up to 0.005 inches in either direction. However, it is important to note that the tolerance for thickness can be different for different grades and types of steel flat bars, as well as for different applications. Therefore, it is crucial to consult the relevant specifications and guidelines provided by the manufacturer or industry standards to determine the specific tolerance for thickness in steel flat bars for a particular application.

- Q: What are the common applications of steel flat bars?

- Due to their versatility and durability, steel flat bars find wide-ranging applications in various industries. In construction, these bars provide strength and stability to buildings and infrastructure, serving as structural support in beams, columns, and trusses. They are also commonly used in the construction of stairs, walkways, and platforms, distributing weight evenly. The manufacturing industry heavily relies on steel flat bars as raw materials for machinery, equipment, and tools. These bars can be machined, welded, and molded into different shapes and sizes, making them ideal for manufacturing components like brackets, frames, and supports. In the automotive industry, steel flat bars are utilized in the production of car frames, chassis, and suspension systems. Their high strength and impact resistance contribute to the safety and stability of vehicles. They are also found in various automotive accessories such as roof racks, bull bars, and tow hooks. Steel flat bars are extensively used in general fabrication by metal fabricators. They can be easily cut, bent, and shaped to meet specific design requirements, making them an excellent choice for creating furniture, decorative items, and industrial equipment. In summary, steel flat bars offer strength, versatility, and reliability in a wide range of construction, manufacturing, automotive, and general fabrication projects across multiple industries.

- Q: Can steel flat bars be used for making frames or supports for signage?

- Yes, steel flat bars can be used for making frames or supports for signage. Steel flat bars are strong, durable, and versatile, making them suitable for constructing sturdy frames or supports to hold signage in place.

- Q: How do you prevent rusting on steel flat bars?

- To prevent rusting on steel flat bars, there are several steps you can take: 1. Keep the bars dry: Moisture is a major contributor to rusting. Ensure that the flat bars are stored in a dry environment and avoid exposing them to water or excessive humidity. 2. Apply a protective coating: Applying a protective coating is an effective way to prevent rust formation. Options include paint, varnish, or a specialized rust-resistant coating. Make sure to choose a coating that is specifically designed for steel and can withstand the intended use of the flat bars. 3. Use galvanized steel: Galvanization is a process that involves coating steel with a layer of zinc. This protective layer acts as a barrier against moisture and prevents rusting. Galvanized steel flat bars are highly resistant to corrosion and can be a great choice if rust prevention is a priority. 4. Maintain proper ventilation: If the steel flat bars are used in an environment with high humidity or exposure to chemicals, adequate ventilation is crucial. Proper airflow helps to prevent the accumulation of moisture, reducing the risk of rust formation. 5. Regular cleaning and inspection: Regularly cleaning the steel flat bars and inspecting them for any signs of rust or damage is essential. If any rust spots are detected, they should be promptly addressed to prevent further corrosion. 6. Store the bars properly: When storing steel flat bars, ensure they are kept in a dry location away from any potential sources of moisture. Consider using storage racks or shelves to prevent direct contact with the ground or other surfaces that may accumulate moisture. By following these preventive measures, you can significantly reduce the chances of rusting on steel flat bars and prolong their lifespan.

- Q: What are the standard tolerances for steel flat bars?

- The standard tolerances for steel flat bars vary depending on the specific manufacturing standards and requirements. However, common tolerances for steel flat bars typically include dimensions such as width, thickness, and length. These tolerances are usually specified in terms of plus or minus a certain amount, such as ±0.005 inches for width and ±0.010 inches for thickness. It is important to consult the relevant industry standards or the specific manufacturer's guidelines to determine the exact tolerances for steel flat bars.

- Q: Can steel flat bars be used for making signage?

- Yes, steel flat bars can be used for making signage. Steel is a durable and versatile material that can be easily cut, shaped, and welded to create various designs and sizes of signage. Steel flat bars can be used as the main frame or structure for the sign, providing stability and support. They can also be used as decorative elements, adding a sleek and modern look to the signage. Additionally, steel is resistant to weather and corrosion, making it suitable for both indoor and outdoor signage. Overall, steel flat bars are a practical and reliable choice for making signage.

- Q: How do I determine the strength of a steel flat bar?

- To determine the strength of a steel flat bar, you need to consider its grade, which indicates the alloy composition and mechanical properties of the steel. The grade is usually marked on the bar or can be obtained from the manufacturer's specifications. Additionally, you can refer to industry standards or consult engineering handbooks that provide information on the strength and properties of various steel grades.

- Q: Are steel flat bars used in the automotive industry?

- Steel flat bars are widely utilized in the automotive industry. They find application in the fabrication of chassis frames, suspension components, seat frames, and door reinforcements. The utilization of steel flat bars brings forth numerous benefits in automotive manufacturing, encompassing remarkable strength, durability, and cost-effectiveness. Their adaptability and ease of shaping and welding render them a favorable option for a multitude of automotive structural and non-structural components. Furthermore, steel flat bars exhibit exceptional resistance to impact and fatigue, thus guaranteeing the safety and longevity of vehicles.

- Q: Can steel flat bars be used for making agricultural equipment?

- Yes, steel flat bars can be used for making agricultural equipment. Steel is a durable and versatile material that is commonly used in the construction of agricultural machinery. Steel flat bars can be shaped and welded to create various components and structures required for agricultural equipment such as plows, cultivators, and harrows. The strong and rigid nature of steel flat bars makes them suitable for withstanding the demanding conditions and pressures experienced in agricultural operations. Additionally, steel is resistant to corrosion and can withstand exposure to moisture and other elements commonly found in agricultural environments. Overall, steel flat bars are a popular choice for manufacturing agricultural equipment due to their strength, durability, and versatility.

- Q: Are steel flat bars corrosion resistant?

- Steel flat bars are not inherently corrosion resistant. However, the level of corrosion resistance depends on the type of steel used and any additional treatments or coatings applied to the surface of the bars. Stainless steel flat bars, for example, are highly corrosion resistant due to the presence of chromium, which forms a protective oxide layer on the surface. On the other hand, carbon steel flat bars are more prone to corrosion, especially in environments with high moisture or exposure to corrosive substances. To enhance the corrosion resistance of carbon steel flat bars, they can be galvanized or coated with protective coatings like paint or epoxy. Overall, it is important to consider the specific type of steel and any additional treatments when assessing the corrosion resistance of steel flat bars.

Send your message to us

Flat Steel A36 Q235 SS400 Slit Ms Carbon Mild Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords