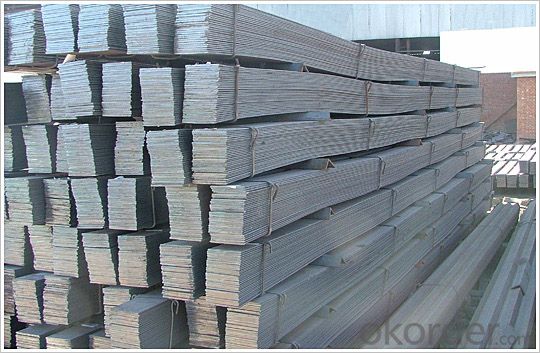

Flat Bars Hot Rolled Perforated (Hot Galvanized) Hot Dipped

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 29 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | within 10 days after receipt of deposit |

| Delivery Detail: | In bundles, load in containers |

Specifications

Hot dipped galvanized steel flat, galvanized steel flat bar

1.High quality

2. seafreight package

3.Lead time

4.MTC

Product Description

Hot dipped galvanized steel flat, galvanized steel flat bar

SPECIFICATIONS (MM)

HOT ROLLED FLAT BAR

1. STANDARD: GB704-1988

2. GRADE: Q195,Q215,Q235 Q345,ST-37,ST-53,S275JR.S355JR,SS400

3. THICKNESS: 8-30MM

4. WIDTH: 40-120MM

5. LENGTH: 6M/5.8M/3M/2M OR ACCORDING TO CUSTOMER'S REQUEST

STAINLESS FLAT BAR

1. GRADE: 201/202/ 201/201/301/304/304L/316/316l/317/310/

310S/309/309S /321/410/410S/420/430/439/416

2. TECHNIC: THICKNESS ABOVE 10MM IS FOR HOT ROLLED STAINLESS FLATE BA,

THICKNESS BELOW 10MM IS FOR COLD DRAWN STAINLESS FALAT BAR

4. WIDTH: 10-1000MM

5. LENGTH: 5.8M,6M ORACCORDING TO CUSTOMER'S REQUEST

ALLOY STEEL FLAT BAR PRICE PER TON

1. GRADE: 40Cr,42CrMo,40Mn,20CrMo,30CrMo,35CrMo,65Mn,60SiMnA,60CrMoA

50CCrVA

2. TECHNIC: HOT ROLLED ALLOY STEEL FLATE BA,

COLD DRAWN ALLOY STEEL FALAT BAR

4. WIDTH: 10-1000MM

5. LENGTH: 5.8M,6M ORACCORDING TO CUSTOMER'S REQUEST

SLITED FLAT BAR

1. STANDARD: GB704-1988

2. GRADE: Q195,Q215,Q235 Q345,ST-37,ST-53,S275JR.S355JR,SS400

3. THICKNESS: 1.5-30MM

4. WIDTH: 10-1000MM

5. LENGTH: 2M/3M/5.8M,6M ORACCORDING TO CUSTOMER'S REQUEST

- Q: What are the common forming techniques used for steel flat bars?

- Some of the common forming techniques used for steel flat bars include hot rolling, cold rolling, and extrusion. Hot rolling is a process where the steel is heated above its recrystallization temperature and passed through a series of rollers to reduce its thickness and shape it into a flat bar. This technique is commonly used to produce steel flat bars with precise dimensions and a smooth surface finish. Cold rolling, on the other hand, involves passing the steel through rollers at room temperature. This process is typically used to further refine the thickness and surface finish of the steel flat bar produced through hot rolling. Cold rolling can also increase the strength and hardness of the steel. Extrusion is another forming technique that involves forcing the steel through a die to shape it into a flat bar. This process is commonly used for producing steel flat bars with complex cross-sectional profiles or when there is a need for a high degree of precision in the final product. Other forming techniques for steel flat bars may include bending, shearing, and welding. Bending is often used to achieve specific shapes or angles in the flat bar, while shearing is used to cut the flat bar to the desired length. Welding is a joining process that can be used to connect multiple steel flat bars together or to other steel components.

- Q: How can copper clad steel ground electrode and galvanized flat steel be welded?

- If you want it to work well, use heat release welding, and if you take into account the cost budget, there are connectors, connectors that are just mechanical connections

- Q: What are the different types of coatings available for steel flat bars?

- Steel flat bars can be coated with various types of coatings, each with their own unique advantages and properties. Some common options include galvanized coatings, powder coatings, epoxy coatings, paint coatings, anodizing, and phosphate coatings. Galvanized coatings are widely used and involve applying a layer of zinc to the steel surface. This provides excellent resistance to corrosion and makes them suitable for outdoor applications. Powder coatings, on the other hand, involve applying a dry powder that is then cured under heat to form a protective layer. This type of coating offers durability, resistance to chipping, and a wide range of color options. It is often used for decorative purposes or when a durable and aesthetic finish is desired. Epoxy coatings are popular for steel flat bars that will be exposed to corrosive environments. They are applied as a liquid and then cured to form a hard, protective layer. Epoxy coatings provide excellent chemical resistance and can withstand exposure to acids, alkalis, and other corrosive substances. Paint coatings are a versatile option, offering both protection and aesthetics. They can be applied in various colors and finishes, providing a decorative and protective layer. However, periodic maintenance and touch-ups may be required to maintain their effectiveness. Anodizing is primarily used for aluminum but can also be applied to steel flat bars. It involves creating an oxide layer on the surface of the metal, enhancing its corrosion resistance and providing an attractive finish. Anodized coatings are particularly suitable for architectural and decorative applications. Phosphate coatings are a type of conversion coating that chemically reacts with the steel surface to form a protective layer. They offer excellent adhesion, corrosion resistance, and improved paint adhesion. Phosphate coatings are commonly used as a pre-treatment before applying paint or powder coatings. In conclusion, the choice of coating for steel flat bars depends on specific requirements such as corrosion resistance, durability, aesthetics, and environmental conditions. The available options include galvanized coatings, powder coatings, epoxy coatings, paint coatings, anodizing, and phosphate coatings.

- Q: Can steel flat bars be used for fencing or gates?

- Yes, steel flat bars can be used for fencing or gates. Steel flat bars are strong, durable, and resistant to corrosion, making them suitable for outdoor applications. They can be welded or bolted together to create a sturdy fence or gate structure. Additionally, steel flat bars can be easily customized and shaped to fit specific design requirements. Whether it's for residential, commercial, or industrial use, steel flat bars provide a reliable and long-lasting solution for fencing or gating needs.

- Q: The steel, steel and flat steel, round steel bar and what is the difference?

- There is not much difference between round bar and steel bar, but the diameter range should be different. Can you hold it with hand?Inside the details of the difference, you can go to the tool book to see.

- Q: Are steel flat bars available with pre-drilled holes?

- Yes, steel flat bars are available with pre-drilled holes. These pre-drilled holes are commonly used to facilitate easy installation and provide a secure attachment point for various applications. Pre-drilled holes can be found in different sizes and patterns, depending on the specific requirements of the project. The availability of pre-drilled holes on steel flat bars offers convenience and time-saving benefits for users, as it eliminates the need for additional drilling or machining. Whether it is for construction, furniture assembly, or industrial applications, steel flat bars with pre-drilled holes are readily available and widely used in various industries.

- Q: What are the different types of steel flat bar finishes for architectural purposes?

- For architectural purposes, there exist numerous steel flat bar finishes that are commonly utilized. These finishes serve to enhance the visual appeal of the steel flat bar and guard against corrosion. One well-liked finish is the plain or mill finish, which denotes the untreated surface of the steel. This particular finish is commonly employed in industrial or utilitarian settings where appearance is not of utmost importance. Another frequently used finish is the brushed finish, otherwise known as the satin finish. Achieved through the use of abrasive materials to brush the steel surface, this finish results in a textured and slightly reflective appearance. Brushed finishes are often favored in modern and contemporary architectural designs. For steel flat bars, a polished finish is also an option. This finish involves grinding and polishing the steel surface to create a smooth and reflective appearance. Particularly preferred in high-end architectural projects, polished finishes impart a luxurious and elegant look. To protect against corrosion, a galvanized finish can be applied to the steel flat bar. This finish entails immersing the steel in molten zinc, which forms a protective layer on the surface. Galvanized finishes are commonly employed in outdoor architectural applications, such as fences, handrails, and building facades. Lastly, a powder-coated finish is another possibility. It involves applying a dry powder to the steel surface and subsequently curing it under heat. This finish provides a durable and decorative coating, available in a wide range of colors and textures. Powder-coated finishes are often utilized in architectural projects where color customization is desired. In summary, the various steel flat bar finishes for architectural purposes encompass the plain or mill finish, brushed finish, polished finish, galvanized finish, and powder-coated finish. Each of these finishes possesses distinctive characteristics and advantages, enabling architects and designers to achieve their desired aesthetic and functional objectives.

- Q: Are steel flat bars suitable for food processing or hygiene-sensitive environments?

- Steel flat bars are generally not suitable for food processing or hygiene-sensitive environments. Despite being strong and durable, steel is not naturally resistant to corrosion or contamination. In such environments, it is typically advised to use stainless steel instead. Stainless steel has a higher chromium content, which forms a protective layer on the metal's surface, preventing corrosion, staining, and bacterial growth. Therefore, stainless steel is a more appropriate option for applications where cleanliness and hygiene are crucial.

- Q: What are the different certifications and standards for steel flat bars?

- There are several certifications and standards that apply to steel flat bars, ensuring their quality and suitability for various applications. Some of the most common certifications and standards include: 1. ASTM International (formerly known as the American Society for Testing and Materials): ASTM A108 is a standard specification for steel bars, carbon and alloy, cold-finished, while ASTM A36 is a standard specification for carbon structural steel that covers carbon steel shapes, plates, and bars of structural quality. 2. American Iron and Steel Institute (AISI): AISI 1018 is a common low carbon steel grade that is often used in steel flat bars. This grade conforms to AISI standards and is known for its excellent weldability and machinability. 3. Society of Automotive Engineers (SAE): SAE 4140 is a high-strength steel alloy commonly used in steel flat bars. It meets the SAE J404 standard, which specifies chemical composition limits for carbon and alloy steel bars. 4. European Norms (EN): EN 10025-2 is a standard specification for hot-rolled products of structural steels, including steel flat bars, that specifies technical delivery conditions for non-alloy structural steels. 5. International Organization for Standardization (ISO): ISO 683-3 is a standard that specifies the technical delivery requirements for steel bars, hot-rolled or forged, in various grades and conditions. 6. British Standards (BS): BS EN 10025-2 is a British standard that aligns with the European Norms and specifies the technical delivery conditions for non-alloy structural steels, including steel flat bars. It is important to note that specific applications may require additional certifications or standards. For example, steel flat bars used in construction may need to meet specific building codes or regulations set by local authorities. Additionally, industries such as aerospace or automotive may have their own unique certifications or standards to ensure the performance and safety of steel flat bars used in their applications.

- Q: How do you prevent scaling or oxidation on steel flat bars during heat treatment?

- To prevent scaling or oxidation on steel flat bars during heat treatment, several measures can be taken: 1. Use a protective atmosphere: One effective method is to heat treat the steel flat bars in a controlled atmosphere such as a vacuum or an inert gas environment like nitrogen or argon. This prevents the steel from coming into contact with oxygen, thereby minimizing the risk of oxidation. 2. Apply a protective coating: Another approach is to apply a protective coating on the surface of the flat bars before heat treatment. This can be done by using various coatings such as ceramic, refractory, or metallic coatings. These coatings act as a barrier between the steel and the surrounding atmosphere, preventing oxidation. 3. Use a reducing atmosphere: Heat treating the steel in a reducing atmosphere, such as hydrogen or a mixture of hydrogen and nitrogen, can also prevent scaling and oxidation. The reducing atmosphere helps to remove any oxygen present and prevents the formation of oxides on the surface of the steel. 4. Control the heating process: Proper control of the heating process is crucial in preventing scaling and oxidation. Rapid heating and cooling rates should be avoided as they can lead to excessive scaling. Slow and controlled heating with proper temperature ramping can help reduce the chances of oxidation. 5. Clean the surface: Prior to heat treatment, it is important to thoroughly clean the surface of the steel flat bars. Any contaminants, such as dirt, grease, or oils, can promote scaling and oxidation. Surface cleaning methods like degreasing, pickling, or mechanical cleaning can be employed to remove these contaminants. By implementing these preventive measures, the risk of scaling or oxidation on steel flat bars during heat treatment can be significantly reduced, ensuring a high-quality final product.

Send your message to us

Flat Bars Hot Rolled Perforated (Hot Galvanized) Hot Dipped

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 29 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords