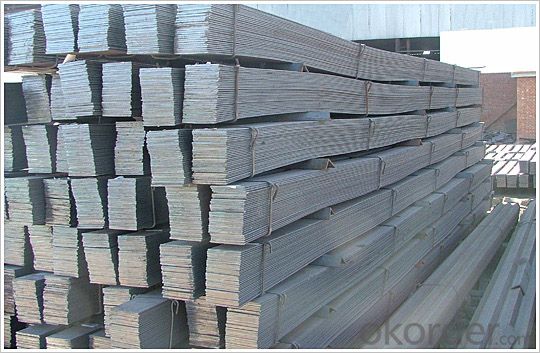

Hot Rolled Steel Flat Bars Perforated Hot Galvanized Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Steel Flat Bars Perforated (Hot Galvanized)Made In China at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel Flat Bars Perforated (Hot Galvanized)Made In China are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Steel Flat Bars Perforated (Hot Galvanized)Made In China are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specification of Mild Steel Flat Bar

Commodity: Mild Steel Flat Bar

Standard: GB;JIS

Material: Q195-235;SS400

Brand name: FLATSPACE

Origin place: China

Thickness: 3mm-30mm

Width:20mm-200mm

Length: Max 12m

Certification: SGS/BV

Packaging & Delivery of Hot Rolled Steel Flat Bars

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: Can steel flat bars be used in food processing industries?

- Steel flat bars cannot be used in food processing industries due to their composition of carbon steel, which has the potential to corrode and react with food substances. This can result in food contamination and compromise its safety and quality. In order to maintain food hygiene and safety, it is imperative for food processing industries to prioritize the use of materials that are food-grade and resistant to corrosion, such as stainless steel. Stainless steel is an ideal choice as it does not react with food, is easy to clean, and possesses exceptional durability. Therefore, the utilization of stainless steel flat bars or other food-grade materials is crucial for ensuring the hygiene and safety of processed food products in the food processing industries.

- Q: How do steel flat bars compare in terms of strength and durability?

- Steel flat bars are known for their exceptional strength and durability. Due to their flat shape, they offer enhanced load-bearing capacities and resistance to bending or warping. Additionally, steel flat bars are highly resilient against external impacts and corrosion. Overall, they are a reliable choice for applications requiring robustness and longevity.

- Q: Are steel flat bars suitable for making architectural or decorative panels?

- Indeed, steel flat bars prove to be a suitable choice when it comes to crafting architectural or decorative panels. Steel, being an adaptable material, offers numerous benefits for such purposes. To begin with, steel exhibits remarkable durability, enabling it to withstand diverse weather conditions and consequently making it suitable for both indoor and outdoor applications. Furthermore, steel flat bars can be easily shaped and manipulated into various designs and patterns, allowing for limitless possibilities in creating unique architectural or decorative panels. Moreover, steel imparts a sleek and contemporary appearance, thereby enhancing the overall aesthetic appeal of the panels. Additionally, steel stands out as a cost-effective alternative compared to other materials, contributing to its popularity in architectural and decorative projects. To conclude, considering their durability, versatility, and aesthetic appeal, it is clear that steel flat bars are unquestionably a suitable choice for making architectural or decorative panels.

- Q: Are steel flat bars suitable for handrail applications?

- Yes, steel flat bars are suitable for handrail applications. Steel flat bars are strong and durable, making them an excellent choice for handrails. They can provide stability and support while also offering a sleek and modern aesthetic. Additionally, steel flat bars are versatile and can be easily customized to fit various handrail designs. They can be painted or coated to enhance their corrosion resistance and can withstand heavy use and constant contact. Overall, steel flat bars are a cost-effective and reliable option for handrail applications.

- Q: Hot dip galvanized flat steel specification 40X4, 60X6 meaning?

- Section size of flat steel * width * thickness. Unit: mm.

- Q: Galvanized flat steel how much is one meter?

- Formula of flat steel: width * thickness * 0.00785 (kg/m), zinc coating weight: 1.06Galvanized pipe formula: (outer diameter wall thickness) * wall thickness * 0.02466 * 1.06, DN25 galvanized pipe outer diameter 33.5, GB thickness 3.25, weight: 2.57kg/m, DN32, outer diameter 42.3, wall thickness 3.25, weight: 3.32kg/m. DN stands for nominal caliber.Angle formula (approximate): edge width * thickness * 0.015, 4# angle iron weight 2.422kg/m

- Q: Can steel flat bars be used for architectural purposes?

- Yes, steel flat bars can be used for architectural purposes. They are often used in architectural designs for various applications such as support structures, decorative elements, and framing. Steel flat bars provide strength, durability, and versatility, making them suitable for various architectural projects.

- Q: What industries commonly use steel flat bars?

- Steel flat bars find widespread use across a diverse range of industries owing to their versatility and durability. Construction, manufacturing, automotive, infrastructure, and engineering are some of the sectors that frequently employ steel flat bars. Within the construction industry, steel flat bars serve multiple purposes, functioning as support beams, frames, braces, and structural components in buildings and bridges. By offering strength and stability, they prove ideal for withstanding heavy loads and pressure. In manufacturing, steel flat bars play a crucial role in the fabrication of machinery, equipment, and tools. Their malleability allows for easy shaping and machining, enabling them to meet specific requirements and suit various manufacturing processes. The automotive industry relies on steel flat bars extensively, particularly in the production of vehicle chassis and body frames. These bars provide the necessary strength and rigidity to endure the stresses and strains endured by automobiles, ensuring safety and durability. Infrastructure projects such as highways, railways, and airports make extensive use of steel flat bars as well. They are employed in the construction of beams, columns, and other structural elements, furnishing the requisite strength to bear heavy loads and withstand environmental conditions. Engineering industries heavily depend on steel flat bars for a wide array of applications. These bars are commonly utilized in the fabrication of machinery, equipment, and components that necessitate strength, resilience, and versatility. Furthermore, they are used in constructing support structures, frames, and braces required for various engineering projects. In conclusion, steel flat bars are widely utilized in the construction, manufacturing, automotive, infrastructure, and engineering sectors. Their versatility, strength, and durability render them indispensable for numerous applications and projects within these industries.

- Q: Are steel flat bars suitable for machining or drilling?

- Yes, steel flat bars are suitable for machining or drilling as they possess excellent machinability characteristics and can be easily shaped or drilled into desired forms or sizes.

- Q: Can steel flat bars be used for fencing or railing?

- Yes, steel flat bars can be used for fencing or railing. Steel flat bars are commonly used in construction applications due to their strength and durability. They are often used as pickets for fences or as balusters for railings. The flat shape of the bars allows for easy installation and creates a sleek and modern look. Additionally, steel flat bars can be easily customized to match the desired design and can be painted or coated to prevent rust and corrosion. Overall, steel flat bars are a suitable choice for fencing or railing projects due to their sturdiness and versatility.

Send your message to us

Hot Rolled Steel Flat Bars Perforated Hot Galvanized Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords