Steel Flat Bar EN Hot Rolled High Quality China Steel Galvanized

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

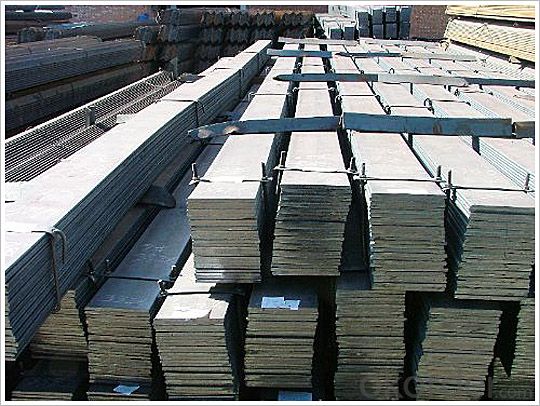

Product Description of Steel Flat Bar EN Hot Rolled High Quality China Steel Galvanized:

OKorder is offering mild stainless steel flat bar for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications of Steel Flat Bar EN Hot Rolled High Quality China Steel Galvanized:

Mild stainless steel flat bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages of Steel Flat Bar EN Hot Rolled High Quality China Steel Galvanized:

OKorder's Steel flat bar are durable, strong, and resist corrosion.

Main Product Features of Steel Flat Bar EN Hot Rolled High Quality China Steel Galvanized:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications of Steel Flat Bar EN Hot Rolled High Quality China Steel Galvanized:

Commodity: High Quality Mild Steel Flat Bar

Standard: GB

Material: Q235

Brand name: FLATSPACE

Origin place: China

Thickness: 3mm-30mm

Width:20mm-200mm

Length: Max 12m

Certification: SGS/BV

Chemical composition of Q235

Alloy No | Grade | Element(%) | ||||

C

| Mn

| S

| P

| Si

| ||

Q235

|

B

|

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

Physical properties of Q235

Alloy No | Grade | Yielding strength point(Mpa) | Tensile strength (Mpa) | Elongation after fracture(%) | ||||||

Thickness (mm) | Thickness (mm) | |||||||||

≤16 | >16--40 | >40--60 | >60--100 | ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | ≥ | |||||||||

Q235 |

B |

235 |

225 |

215 |

205 |

375--500 |

26 |

25 |

24 |

23 |

Usage/Applications of Steel Flat Bar EN Hot Rolled High Quality China Steel Galvanized

Widely used for construction, Machinery manufacturing, Iron tower steel structure, Shipbuilding; Steel grating, Staircase, Bridge, Viaduct, Railway spare parts, Boilers making etc.

Production Flow of High Quality Mild Steel Flat Bar

The steel flat bar is made through three processes:

1.Feeding the material: Feeding the row material (the steel plate) to Slitting Line.

2.Slitting:The steel plate would be slitted into expected width by lengthways cutter.

3. Leveled and cutting: The plat bar would be ground into level by the grinder and then cut into required length.

Packaging & Delivery of High Quality Mild Steel Flat Bar

Packaging Details: The Steel Flat Bars are packed in bundles and loaded in 20 feet/40 feet container, or shipped by bulk cargo ,also we can do as customer's requirements.

Delivery Details:30~45 days upon the receipt of buyer payment by T.T. or L/C.

- Q: How do steel flat bars contribute to the overall stability of a structure?

- Steel flat bars contribute to the overall stability of a structure by providing strength and rigidity. Due to their flat shape, they offer excellent load-bearing capacity and resistance against bending or twisting forces. These bars can be strategically placed throughout the structure, serving as support beams, braces, or reinforcements to distribute and minimize the impact of external loads. Their high tensile strength and durability make them essential components in various construction applications, enhancing the overall stability and structural integrity of buildings, bridges, and other infrastructures.

- Q: How do steel flat bars contribute to the overall sustainability of a structure?

- Steel flat bars contribute to the overall sustainability of a structure by providing several key benefits. Firstly, steel is a highly durable and long-lasting material, which means that structures constructed with steel flat bars have a longer lifespan and require less frequent maintenance or replacement, reducing the overall environmental impact. Additionally, steel is a highly recyclable material, and steel flat bars can be easily recycled and reused at the end of their life cycle, making them a more sustainable choice compared to other materials. Moreover, steel has a high strength-to-weight ratio, allowing for lighter and more efficient structures, which can reduce the amount of materials needed and minimize the carbon footprint of construction projects. Overall, the use of steel flat bars enhances the sustainability of structures through durability, recyclability, and efficient design.

- Q: Earthing flat steel and earthing main line

- The flat steel is connected to the ground system, and the grounded line is connected to the protected equipment

- Q: How do you determine the length of a steel flat bar?

- To determine the length of a steel flat bar, you can use a measuring tape or ruler and measure from one end to the other in a straight line.

- Q: The difference between galvanized flat steel 40*4 and galvanized flat steel 80*8 is the difference on the material list!

- There are many kinds of flat steel, Q235A/B/C, mainly depends on the location of your specific requirements, what is needed?;

- Q: Are steel flat bars available in different shapes, such as round or square?

- No, steel flat bars are not available in round or square shapes. They are specifically designed with a rectangular cross-section, characterized by a long width and a relatively small thickness.

- Q: Can steel flat bars be used for making telecommunications industry equipment?

- Telecommunications industry equipment can indeed be made using steel flat bars. Steel is a widely utilized material in the manufacturing of various equipment owing to its robustness, longevity, and cost-effectiveness. The construction of equipment racks, supports, brackets, and frames for housing telecommunications equipment like servers, switches, routers, and antennas can all make use of steel flat bars. These bars' flat shape permits simple fabrication and customization to meet specific design requirements. Furthermore, steel's corrosion resistance is vital for telecommunications equipment that may encounter harsh environmental conditions. All in all, steel flat bars serve as a fitting option for the construction of telecommunications industry equipment.

- Q: How do steel flat bars contribute to the overall longevity of structures?

- Several factors contribute to the overall longevity of structures, and steel flat bars play a crucial role in this regard. They offer structural strength and stability, making them essential elements in construction projects. The high strength-to-weight ratio of steel enables the creation of efficient and lightweight structures, reducing the load on the foundation and other supporting elements. Furthermore, steel flat bars possess excellent corrosion resistance, which is vital for structures exposed to harsh environmental conditions. Corrosion can gradually weaken a structure, necessitating expensive repairs or even replacement. However, steel's inherent resistance to corrosion helps prevent this degradation, ensuring the longevity of the structure. Additionally, steel flat bars exhibit remarkable durability, enabling them to withstand heavy loads and extreme weather conditions. They are resistant to warping, twisting, or bending, ensuring the stability and integrity of the structure over time. This durability reduces the need for frequent maintenance or reinforcement, thus extending the structure's lifespan. Moreover, steel flat bars offer versatility, as they can be easily fabricated and customized to meet specific design requirements. This flexibility empowers architects and engineers to create innovative and efficient designs capable of withstanding various stresses and strains. The adaptability of steel flat bars to different shapes and sizes ensures seamless integration into the overall construction, enhancing its longevity and performance. In conclusion, steel flat bars significantly contribute to the overall longevity of structures by providing strength, durability, corrosion resistance, and versatility. Their robustness and ability to withstand heavy loads and adverse conditions make them an ideal choice for construction, ensuring that structures can endure the test of time.

- Q: Are steel flat bars suitable for earthquake-prone areas?

- Yes, steel flat bars are suitable for earthquake-prone areas. Steel is a strong and durable material that can withstand seismic forces better than other materials. Flat bars provide structural stability and can be used in various applications such as reinforcing structures, bracing walls, or constructing seismic-resistant frames.

- Q: Can steel flat bars be used for making brackets or supports for electrical installations?

- Brackets or supports for electrical installations can indeed be made using steel flat bars. Steel is renowned for its robustness, longevity, and capacity to endure heavy loads. Construction and engineering projects frequently employ steel flat bars due to their adaptability and dependability. By utilizing steel flat bars for creating brackets or supports in electrical installations, a solid and stable structure can be achieved, guaranteeing the safety and stability of the electrical components. Furthermore, steel exhibits resistance to corrosion, a vital characteristic in electrical installations where exposure to moisture or harsh environments poses a concern. All in all, the strength, durability, and corrosion resistance of steel flat bars make them a fitting choice for crafting brackets or supports in electrical installations.

Send your message to us

Steel Flat Bar EN Hot Rolled High Quality China Steel Galvanized

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords