Fireproof Glasswool / Glass wool insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

It is widely used for heat insulation and sound absorption in industrial workshops, Prefab houses, Portable cabins, warehouses, public facilities, exhibition centers, shopping malls, and a variety of indoor playgrounds, sports stadiums and etc.

Glass wool, which belongs to glass fiber , is a kind of man-made inorganic fiber. It is made from fibrosis glass melt in wool shape, which belongs to inorganic fiber and fiber in its chemical ingredient. Its merit is better in shape, low density and volume, low in thermal conduction, better heat preservation and thermal insulation, fine sound absorption, corrosion-resistant and stable chemical property. Glass wool blanket, glass wool board, glass wool pipe, which made from glass wool, largely use in construction, chemical, electronic, electricity, metallurgy, energy industry and community with good performance in heat preservation, heat insulation, sound absorption.

2.Main features of Glass Wool Blanket:

h): Hydrophobicity

Hydrophobicity glass wool in panel wall bears 99% Hydrophobicity rate. It can easily get dry naturally, which ensure its long-term heat preservation perporty.

i): Light in weight

Glass wool bears good heat preservation and soundproofing property. It’s low density product can meet energy saving requirement. Thus it helps to decrease the weight of building and makes the construction more expedite.

k): construction and installation property

Glass wool, with slender fiber and no dregs, can avoid the scuffing or pruritus irritation.

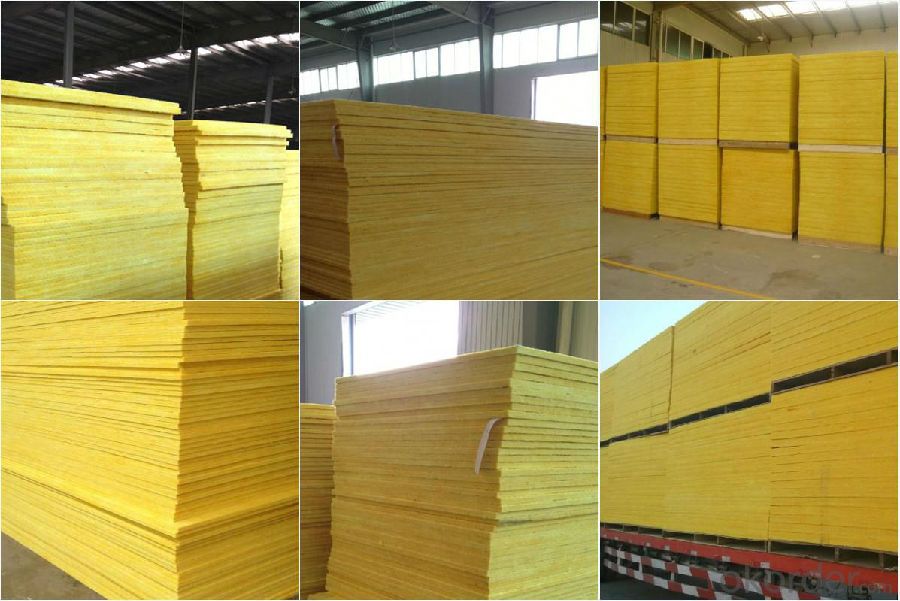

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:How does the width of fiberglass mat tissue affect its installation?

- The width of fiberglass mat tissue affects its installation by determining the amount of coverage it provides per roll. A wider mat tissue will cover a larger area with each roll, reducing the number of rolls needed for installation. This can save time and effort during the installation process. Additionally, a wider width may also provide better overall strength and stability to the installed fiberglass mat tissue.

- Q:How is fiberglass mat tissue bonded to surfaces?

- Fiberglass mat tissue is commonly bonded to surfaces using adhesive materials. The bonding process involves applying the adhesive onto the surface where the fiberglass mat tissue is to be attached. The adhesive is typically a two-part epoxy resin or a specialized fiberglass adhesive that is specifically designed for bonding fiberglass materials. The adhesive is mixed according to the manufacturer's instructions and then spread evenly onto the surface using a brush, roller, or trowel. The fiberglass mat tissue is then carefully placed onto the adhesive-covered surface and pressed down firmly to ensure proper adhesion. The adhesive is left to cure for the recommended amount of time, allowing it to harden and create a strong bond between the fiberglass mat tissue and the surface. This bonding method ensures that the fiberglass mat tissue is securely attached to the surface, providing reinforcement, protection, or other desired properties depending on the application.

- Q:Can fiberglass mat tissue be used for making surfboards?

- Surfboards can indeed be made using fiberglass mat tissue. This material, known for its lightweight yet robust properties, is commonly utilized in constructing surfboards. Typically, it is combined with epoxy resin to form a sturdy and durable surface. By incorporating fiberglass mat tissue, surfboards gain the strength and flexibility necessary to endure the demanding conditions encountered while riding waves. Moreover, the smooth and sleek texture of the material enhances the surfboard's performance and speed. In summary, fiberglass mat tissue is a favored option for constructing high-performance surfboards due to its exceptional strength-to-weight ratio.

- Q:Is fiberglass mat tissue suitable for chemical storage tanks?

- Yes, fiberglass mat tissue is suitable for chemical storage tanks. It is highly resistant to corrosion caused by various chemicals and provides excellent strength and durability to withstand the harsh conditions of chemical storage. Additionally, it helps in preventing leakage and ensures the long-term integrity of the tanks.

- Q:What is the density of fiberglass mat tissue?

- The density of fiberglass mat tissue can vary depending on the specific type and manufacturer. However, on average, fiberglass mat tissue has a density of around 1.5 grams per cubic centimeter (g/cm³) or 1500 kilograms per cubic meter (kg/m³). It is important to note that the density may slightly differ based on the thickness and composition of the fiberglass mat tissue.

- Q:Can fiberglass mat tissue be used for attic insulation?

- Typically, fiberglass mat tissue is not the primary insulation material used in attics. Its purpose is to complement other insulation materials, like fiberglass batts or blown-in insulation, in order to enhance their performance and provide some thermal resistance. Fiberglass mat tissue is frequently utilized as a facing material for insulation products, serving as a vapor barrier or a reinforcement layer. Although it can enhance the durability and moisture resistance of the insulation, its main function is not to offer significant thermal insulation on its own. When insulating an attic, it is more common to employ materials specifically designed for thermal insulation, such as fiberglass batts, cellulose, or spray foam insulation. These materials possess higher R-values and are more effective at minimizing heat transfer, which is essential for maintaining a comfortable indoor temperature and achieving energy efficiency. In conclusion, fiberglass mat tissue may possess insulation properties, but its primary purpose is to enhance the performance of other insulation materials rather than being used as the sole insulation in an attic.

- Q:What is the expected lifespan of fiberglass mat tissue in cryogenic applications?

- The expected lifespan of fiberglass mat tissue in cryogenic applications can vary depending on various factors such as the quality of the material, the specific cryogenic environment, and the maintenance and handling practices. Generally, fiberglass mat tissue is known for its excellent insulation properties and resistance to extreme temperatures. It is commonly used in cryogenic applications to provide thermal insulation and structural support. In well-maintained and controlled cryogenic environments, fiberglass mat tissue can have a lifespan of several decades. However, it is important to note that factors such as exposure to intense thermal cycling, mechanical stress, and chemical exposure can affect the performance and lifespan of the material. To ensure the longevity of fiberglass mat tissue in cryogenic applications, regular inspections, maintenance, and adherence to manufacturer's guidelines are crucial. It is also recommended to monitor and address any signs of degradation or damage promptly to prevent potential issues or failures.

- Q:Does fiberglass mat tissue require any special tools for installation?

- No, fiberglass mat tissue does not require any special tools for installation. It can be easily installed using basic tools such as scissors or a utility knife to cut the mat to the desired size.

- Q:How does fiberglass mat tissue perform in terms of dimensional stability?

- Fiberglass mat tissue performs exceptionally well in terms of dimensional stability. Due to its unique composition and manufacturing process, fiberglass mat tissue exhibits minimal shrinkage or expansion when exposed to temperature variations or moisture. This characteristic makes it an ideal material for various applications where dimensional stability is crucial, such as in the construction industry for reinforcing walls, roofs, or floors. The consistent size and shape of fiberglass mat tissue ensure that it maintains its original dimensions over time, providing long-term durability and reliability. Additionally, its dimensional stability allows for precise cutting, shaping, and installation, reducing waste and increasing efficiency in manufacturing processes. Overall, fiberglass mat tissue offers excellent dimensional stability, making it a favored choice in industries where accurate and stable dimensions are vital.

- Q:Can fiberglass mat tissue be used for electrical transformers?

- No, fiberglass mat tissue cannot be used for electrical transformers. Electrical transformers require materials with specific electrical insulating properties, such as paper or oil-impregnated materials, to ensure efficient and safe operation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fireproof Glasswool / Glass wool insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords