Glass Wool Reinforced Concrete Fireplace Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

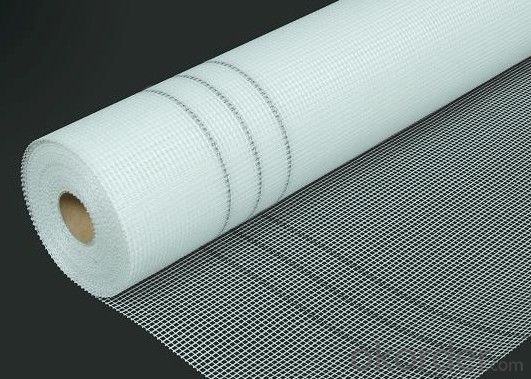

| Place of Origin: | Henan China (Mainland) | Brand Name: | cnbm | Model Number: | 145gsm 1m*50m 5mm*5mm |

| Application: | Wall Materials | Weight: | 145gsm | Width: | 1m-2m |

| Mesh Size: | 5mm*5mm | Weave Type: | Twill Woven | Yarn Type: | C-Glass |

| Alkali Content: | Medium | Standing Temperature: | 500 | Fiber Glass Mesh item No.: | FG5X5-145 |

| Logo printing: | Available | Fiber Glass Mesh label: | price included | OEM: | Available |

| Fiber Glass Mesh feel quality: | Soft and stiff | Alkali-resistant property: | Excellent | Fiber Glass Mesh tensile strength: | Excellent |

| Samples: | Free | Fiber Glass Mesh Delivery time: | Very fast | Trade Assurance: | 100% payment refund |

Packaging & Delivery

| Packaging Details: | PVC bag or Shrink package as inner package, then loaded into Carton or Pallet |

| Delivery Detail: | Within 20 days after receipt of down payment |

is mainly alkali-resistant fiberglass fabric, it made of the C or E glass fiber yarn (main ingredient is a silicate,

good chemical stability) through a special weaving technique, then coated by the anti-alkali and reinforcing agent and treated by high temperature heat finishing. It’s ideal engineering material in construction and decoration industry!

Main characteristics:

1.Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemical corrosion resistant, and strong resin bonding, soluble in styrene.

2.Outstanding process :Include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after 28-day immersion of 5% Na(OH) solution, so that guarantee high strength, high tensility, light weight.

3.Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it own 20% extra strength and beauty surface than normal fiberglass yarn!

4.Strength retention rate > 90%, elongation <1%, the durability of more than 50 years< span="">

5.Good dimensional stability, stiffness, smoothness an difficult to shrink and deformation, good positioning property..

6.Good impact resistance and not easy to be teared.

7.Fire resistant, thermal insulation, sound insulation, insulations etc.

Fiber Glass Application:

1.Wall reinforced material (such as fiberglass wall mesh, GRC wall panels, EPS insulation with the wall board,gypsum board, bitumen etc)

2.Reinforced cement products.

3.Used for Granite, mosaic, marble back mesh etc.

4.Waterproof membrane fabric, asphalt roofing.

5.Framework material for reinforced plastics, rubber products,.

6.Fire board

7.Grinding wheel base fabric.

8.Road surface with geogrid

9.Construction caulking tape etc.

Fiber Glass Specifications:

1.16x16 mesh, 15x14 mesh, 12x12 mesh, 10x10 mesh, 9x9 mesh, 8x8 mesh, 6x6 mesh, 5x5 mesh, 5x4 mesh, 4x4 mesh, 3x3 mesh, 2.5x2.5 mesh, 1x1 mesh and so on

2.Weight/sq.meter: 40g—800g

3.Each roll length: 10m,20m,30m,50m—300m

4.Width: 1m—2.2m

5.Color: White (standard) blue, green, orange, yellow and others.

6.We can produce many specifications and use different packaging according to customers’ requests.

- Q: whether the sound insulation is asbestos good or the glass wool good?

- glass wool has good sound insulation, and it is commonly used in studio, bar, KTV, etc.

- Q: How to increase soundproof performance of houses(with glass wool)?

- Windows need to be soundproof. Curtains need to be thick. Rental house has to change windows and doors. Double-pane glass windows have better sound absorption performance.

- Q: How can I fix the glass cotton insulation board to the wall?

- If you have used composite boards as internal wall, you don't have to deal with the final layer engineering. Since composite boards are smooth both inside and outside, as well as flawless. If you really want to do the surface construction, you will use many materials. Because there are no composite boards with pure plane in the market, they all have grooves on the surface, and the grooves can increase the load bearing strength of composite boards. Supplement: That glass wool composite boards are fireproof?boards with metal surface. With rock wool and glass cotton as main materials, they use high-quality color coating steel plates as plane materials, continuous cotton fiber rock wool and glass wool as core materials, high-density rigid foam polyurethane as filling materials of tongue-and-groove. After high-pressure foaming and curing, automatic compacting, as well as ultra-long double caterpillar track controling, they take shape and become composite materials.

- Q: Does anyone know about the filling materials in the steel stud, is it glass wool or mineral wool?

- Generally, rock wool is the filling materials.

- Q: Which kind of thermal insulation glass wool is the best?

- Insulated wool is good. Rock wool: It is also known as rock cotton, which belongs to mineral wool. It is a fluffy, short and fine fiber made up raw materials like natural rocks and minerals. Rock wool, whose main raw material are natural rocks like basalt, gabbro, dolomite, iron ore, bauxite and more, is an inorganic fiber made by melting at high temperatures and fibering. Rock wool can serve as the insulation material with ablation resistance and high temperature resistance, the sound-absorbing material and insulation material of buildings and equipment, and the reinforcing material of cement product and rubber for sustituting natural asbestos, and high temperature sealing material, high-temperature filtering material and high-temperature catalyst carrier. 1. Insulation properties: Good thermal insulation is the basic property of rock wool and mineral cotton products. 2. Combustion performance. 3. Sound insulation performance: Rock wool and mineral cotton products have excellent sound insulation and sound absorption performance.

- Q: Are foam glass and glass wool the same?

- Different.

- Q: What are the specific differences between glass wool board and glass fiber board?

- Thus, the full name of glass wool is glass fiber wool: There are two kinds of glass fibers from the uses of fiber glass. The fiber used to weave is the continuous fiber, continuous fiber and staple fiber, and the fiber used to make cotton is staple fiber, glass wool board is equivalent to glass fiber board. You are reminded by the Shouchuang Decoration

- Q: Choosing glass wool with proper thickness for piping insulation of Dn900 boiler room.

- If using glass wool, Dn900 pipes must be equipped with insulating layer which is equal to or greater than 100mm. The best working temperature of glass wool does not exceed 300 degrees. Glass wool should keep 0.035 to 0.046 in thermal conductivity. The best working temperature of glass wool does not exceed 300 degrees. It will generate good effect if using aluminum silicate or silicate. Silicate is a closed-cell insulation material with high temperature resistance, so silicate is the most energy-efficient material.

- Q: What is the density of high-temperature glass wool ?

- Centrifugal glass wool felt, steel glass wool felt, roof dedicated centrifugal glass wool felt,aluminum foil glass wool blankets centrifugal glass wool felt. glass wool is added with binding agent and cured under high temperature into panniform. Its bulk density is lighter than panel,good elasticity, cheap and easy construction. Centrifugal glass wool felt major technical indicators: Centrifugal glass wool felt Bulk density: (Kg / m3) 14,16,20,24,32,48 centrifugal glass wool felt Thermal conductivity coefficiency. 0.038w / m.h. ℃ centrifugal glass wool felt Size: Width 1200mm, length 11mm 22mm (negotiable) centrifugal glass wool felt thickness: 25-150mm (negotiable) centrifugal glass wool felt Uses: fireproofing, thermal insulation, sound absorption for high-rise buildings and refrigeration. Thermal and cold insualtion of air-conditioned rooms, vehicles, ships.

- Q: What are the hardnesses of rock wool and glass wool respectively? Are there any requirements on saw blade?

- I do not know about the hardness, but I know that ordinary hacksaw is enough. I'm sorry, I don't have calculation parameters.

Send your message to us

Glass Wool Reinforced Concrete Fireplace Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords