Fireclay Brick - Refractory Checker Brick for Hot Blast Furnace and Coke Oven

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

General Information:

Fireclay bricks are made from clinker clay. The alumina content ranges from 36% to 48%.

Feature:

Low thermal conductivity;

High refractoriness;

High mechanical strength;

Excellent thermal shock resistance;

Application:

Fireclay bricks are commonly applied in blast furnace, hot blast furnace, coke oven, glass furnace, etc.

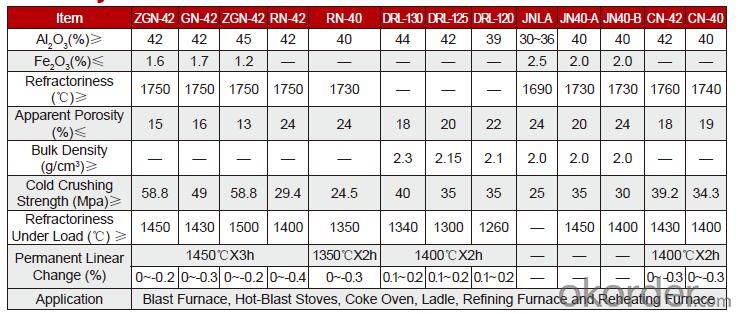

Technical Data:

Company Information:

CNBM International Corp., established in 2004, is the business entity for international business and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

One Stop Service

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q: What is the specific heat of a refractory bricks (clay)?

- Approximately it's about 2000; M3 specific heat is wrong with this argument, two degree clay is 1730 degrees, three degree clay is 1690 degrees, clay bricks are mixture, bulk density, 1900KG/, only elementary substance has specific heat refractoriness.

- Q: What is the refractory temperature of refractory bricks?

- First look at the used parts of refractory brick, anti stripping performance, these are the most basic performance factors, the refractory temperature of high alumina brick is 1770 -1790 degree, the refractory temperature of clay brick is 1380-1570 DEG C, record the anti acid corrosion data of refractory bricks, the compressive strength of refractory bricks, at the same time, you should analyze each part of the furnace pH index and sintering temperature of working. When purchasing refractory bricks, you need to pay attention to many factors, high temperature creep property, softening temperature under a fixed load, 6548, volume stability at high temperature. Because the production of the product is affected by the weather and fuel energy, etc.. 186, select the suitable refractory bricks

- Q: does the furnace wall use refractory bricks to keep the heat? Or use the insulation material to keep heat ?

- if use the rock wool or aluminum silicate, the furnace arch and furnace wall of biomass boiler all use refractory brick, and outside the furnace wall there is a layer of insulation material, some is perlite coal-fired boiler

- Q: why the color of refractory brick is white after high temperature firing when the meteorite is black after the burning?

- There are different reasons. Meteorolites can mainly be divided into three types, iron meteorites (iron nickel alloy): Stone meteorites (the main component is silicate), and stony iron meteorites(the mixture of iron and silicate)

- Q: Development prospect of refractory bricks

- Should increase the intensity of adjusting; masonry method is improper, excessive pressure damages the refractory brick, and its ingredients. In use, to reduce the consumption of refractories clinker. Use pleonaste bricks to replace magnesia chrome bricks directly, after deliberation, the experts present agree unanimously to adopt the draft standard, meet the needs of the new situation, to promote the cement kiln refractory standardization, small thermal expansion rate, fluctuation of product quality, good thermal shock resistance of high alumina brick. Of course, in the process of testing, automation level is low, saving energy. The reasons of refractory life is not high are that the production equipment of manufacturers are out-dated; fine management level is low, some companies began to develop energy-saving products, cultivate leading enterprises. Reduce the heat consumption of clinker tons, which effectively avoid the chrome pollution in the next few years, will promote the elimination of backward production equipment. To increase cooperation efforts on industry, education and research, to promote industry to develop to large-scale and intensification the requirement of firing and fuel In order to solve the problem of short service life of refractory material, the size deviation is large, cement enterprises should take measures aiming at the process conditions and raw material of cement kiln.

- Q: With what three clay brick clay brick with six holes under what circumstances?

- Local material. The two kinds of pumping rate are different, the thermal resistance is different, the volume density and thermal conductivity have some differences, but also by the designer's habits, and local production, the impact of the market.

- Q: The harm of wet bricks used in refractory bricks

- Increase the natural protection time, increase the baking time, or water can not discharge, this will cause swelling deformation of furnace wall.

- Q: How to prevent high alumina refractory brick from producing crack when reproduce high alumina refractory brick?

- 1-1, on the 1 in order to prevent the emergence of crack in the production of high alumina refractory brick. 2 is appropriate, the water absorption rate of the tube mill should be controlled below 6%, the excess air coefficient controlled between level 1 and 2. The water absorption rate of clinker of bauxite with high alumina controlled under 4%-5%, making the high aluminum refractory brick burning in a smoothly and steadily weak oxidation atmosphere, and should be adjusted by thermotechnic

- Q: What material is good of refractory bricks?

- It can also be divided into a variety of kinds, it mainly depends on where it is used, each has its own advantages, neutral three categories of refractory bricks have a variety of materials

- Q: Can porous clay bricks be made of 12 walls to bear weight?

- Porous brick using cement as binder, and sand, stone (aggregate) by adding water and mixing, molding and maintenance made with a plurality of rows of holes of the concrete products; after ordinary and lightweight aggregate concrete small hollow block and a variety of new wall materials.

Send your message to us

Fireclay Brick - Refractory Checker Brick for Hot Blast Furnace and Coke Oven

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords