High Alumina Brick with Excellent Mechanical Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Fireclay Brick Excellent Mechanical Strength

Brief discription for Fireclay Brick

CMAX high alumina refractory bricks are classified according to alumina content ranging from 48% to 90%.

CMAX Fireclay Brick are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln,regenerator, etc.

Brief features for Fireclay Brick

◆Low thermal conductivity

◆Excellent acid and base slagging resistance

◆High refractoriness

◆Excellent thermal shock resistance

◆Excellent mechanical strength

◆Good spalling resistance and wear resistance.

◆Good corrosion resistance.

◆High-temperature creep rate is quite low.

◆Good volume stability at high temperature.

◆Low bulk density, low thermal conductivity, good thermal insulation performance.

Technical data for Fireclay Brick

ITEM | UAL48 | UAL55 | UAL65 | UAL75 | UAL80 | UAL85 | ALP80 |

Refractoriness, ℃ | 1750 | 1770 | 1790 | 1790 | 1810 | 1810 | 1810 |

Apparent Porosity,% | 22 | 22 | 23 | 23 | 20 | 20 | 18 |

C.C.S, Mpa | 39 | 44 | 49 | 53 | 55 | 60 | 100 |

Refractories Under Load (0.2Mpa),℃ | 1420 | 1470 | 1500 | 1520 | 1500 | 1520 | 1550 |

Reheating Linear Change,% | 1450℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 |

Al2O3 Content , % | 48 | 55 | 65 | 75 | 80 | 85 | 82 |

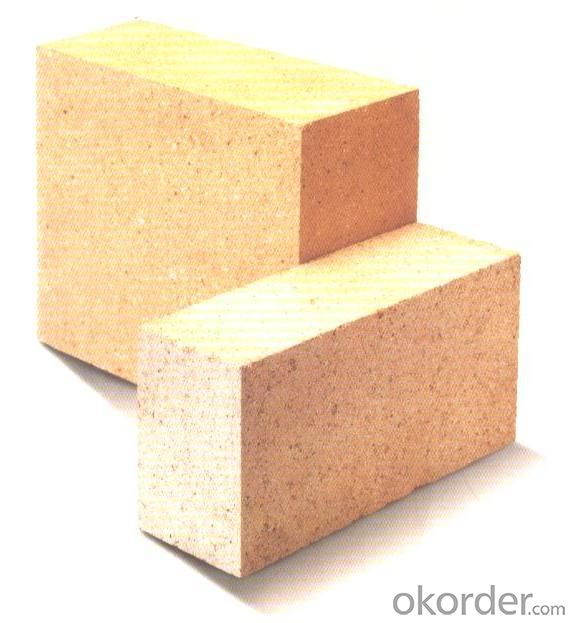

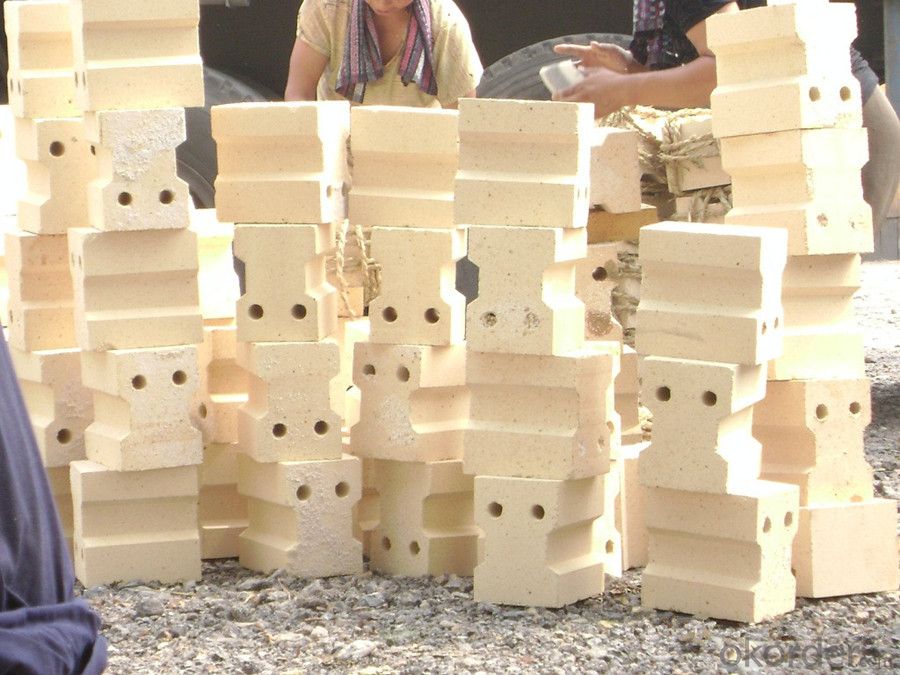

Images/photographs for Fireclay Brick

◆ breif images-different shape for different usage

◆ Packaging for Fireclay Brick

◆ Producing Equipment for Fireclay Brick

◆ Testing Mashines for high alumina bricks

WHO WE ARE?

CNBM International (China National Building Materials Group Corporation) 500 Fortune Company.

we are the main supplier for

ALLIED MINERAL PRODUCTS, INC

REFRACTORIES INCORPORATED

SRS SORG REFRACTORY SYSTEMS GMBH,

SUNWARD REFRACTORIES CO., LTD

LILAMA69-1 JOINT STOCK COMPANY etc.

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

If you have any enquiry,please don't hesitate to contact us,we will provide our best products and services for you!!

- Q: What is the difference between corundum and high alumina??

- The main component of high purity 99 corundum brick is corundum sand,90 corundum brick is mainly composed of corundum sand and a small amount of Suzhou soil, mullite.

- Q: Difference between low creep high alumina brick and ordinary high alumina brick

- Low creep and high alumina brick is based on the theory of "three stones". The combination of bauxite and clay as the main raw material, adding kyanite, andalusite and sillimanite, commonly known as the "three stone" control, physicochemical index and size composition, using alumina mullite corundum + + raw materials such as technical scheme. In the production process, first to detect and control indexes of raw materials, crushing, grinding, sieving process, according to the distribution ratio of ingredients, the size and moisture control of mud mixing after to meet the requirements of forming and molding machine, the use of qualified abrasives, blow molding control number, size and flash at the same time, the detection efficiency of semi-finished products and meet the requirements. Production process: high temperature calcination of high-grade alumina, adding small creep rate of high temperature materials, by high-pressure molding and high temperature firing. It has the characteristics of high strength, low creep rate and high use temperature. Widely used in high temperature furnace, hot air furnace hearth lining, brick and so on.

- Q: What are the alloy wear resistance materials?

- KNMn19Cr2 (patent) high manganese alloy (ZGMn13Cr2MoRe), super high manganese alloy (ZGMn18Cr2MoRe); two: anti-wear chromium cast iron series: such as high, medium and low chromium alloy cast iron (Cr15MOZCu); three: wear resistant alloy steel series: such as, low and high carbon multi metal combined steel (such as ZG40SiMnCrMO and ZG35Cr2MoNiRe); four: ADI (ADI) series; five: all kinds of composite or gradient material and hard alloy materials, nano KN alloy (patent product): such as chromium carbide composite (Cr2C3+Q235), high-energy ion osmosized tungsten carbide materials (WCSP), high toughness of cemented carbide (YK25.6), KN999 nano alloy (Beijing Naimo patent) etc.;

- Q: How much is one ton / ton of high alumina refractory brick?

- The price of high alumina refractory bricks is not equal, according to the quality index of GB2988-2012

- Q: The difference between ordinary and diatomite brick refractory brick

- To say the difference, the material is the biggest difference. There are diatomite brick density, compressive strength of small brick kiln belongs to the outer thermal insulation, and heavy refractory brick kilns for multi village in direct contact with the flame, high temperature resistance, good compressive strength, but no insulation. Hope to help you.

- Q: What does refractory consist of?

- According to the chemical characteristics of refractory raw materials can be divided into acidic refractory materials, such as silica, zircon etc.; neutral refractory raw material, such as corundum, bauxite, mullite (acidic) (acidic), Ge (alkaline) iron and graphite; alkaline refractory materials, such as magnesite, dolomite, magnesium sand calcium sand.

- Q: The difference between light high alumina brick and heavy aluminum brick

- Lightweight high alumina brick, also called high alumina insulation brick. Alumina content of 48% or more, mainly from mullite and glass phase or corundum composition of lightweight refractory. Volume density 0.4 - 1.35g/cm3. Porosity 66% - 73%, compressive strength 1 - 8MPa. Better thermal shock resistance. Usually, a high alumina clinker is added with a small amount of clay. After grinding, it is poured and shaped in the form of slurry by gas generation or foam method, and it is fired at 1300 - 1500 DEG C. Sometimes industrial alumina can be used instead of some bauxite clinker. Used for lining and insulation of masonry kilns, as well as for areas where there is no strong, high temperature molten material erosion and erosion. When contacting the flame directly, the surface contact temperature shall not be higher than 1350 degrees centigrade.

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- The super high alumina brick in high alumina refractory brick has the highest refractoriness, and the corresponding production cost is higher.

- Q: How high can aluminum bricks expand at 80O degrees of heat?

- When an object is heated, the particle moves faster and thus occupies additional space. This phenomenon is called dilation.

- Q: The difference between clay bricks and clay bricks

- Clay brick is a small building with artificial bulk. Also called sintered brick. Solid clay brick is one of the oldest building materials in the world. It is a building material that is loved by the people.

Send your message to us

High Alumina Brick with Excellent Mechanical Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords