Fiberglass Mat Tissue from Italy Supplier - Fiberglass Unidirectional Fabric 350gsm 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

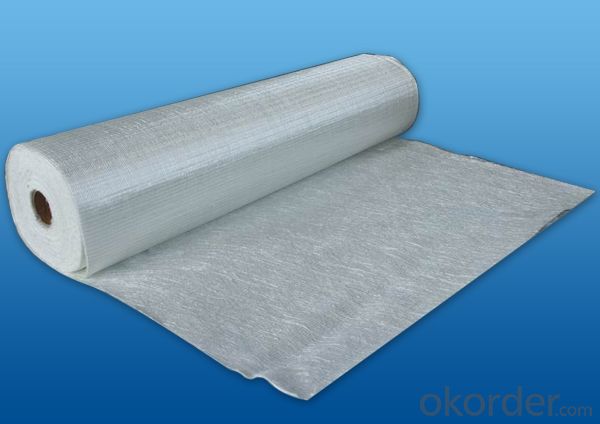

Introduction of E-glass Chopped Strand Mat

E glass chopped strand mat is made from fiberglass strands chopped to length and bonded together

with powder binder. Chopped strand mat is used primarily for hand lay-up processes, filament winding and press molding of FRP products. Typical products include bathroom

accessories, pipe, building materials, automobiles, furniture and other FRP products.

This products ischaracterized bg good combination of resin,easg operation ,good wet strengthretention,good laminate transparency

E glass chopped strand mat is made from fiberglass strands chopped to length and bonded together

with powder binder. Chopped strand mat is used primarily for hand lay-up processes, filament winding and press molding of FRP products. Typical products include bathroom

accessories, pipe, building materials, automobiles, furniture and other FRP products.

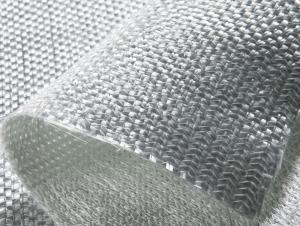

Features of E-glass Chopped Strand Mat

1.Warp and weft rovings aligned in a parallel,flat manner and uniform tension .

2.Densely alighed fibers,providing high dimensional stability ans easy handing .

3.Good moldability,fast and complete resin wet-out ,enabling high productively .

4.Good transporsision and hign strength of the composite products.

5.Even thickness ,no fuzz ,no stain.

6.Fast wet-out ,products with high strength ,little loss for strength in damp situation.

7.fiberglass woven roving has the features of : high tensile strength, corrosion resistance, flame retardance,insulativity.main function

8.applied to hand lay-up process

9.to reinforce UP resin

10.even thickness and flawless

11.good performance of processability in moulded parts

12.properties guaranteed under moisture condition

13.excellent mechanical strength during production of finished products

Features of E-glass Chopped Strand Mat

1.the composit products have high dry and wet tensile strenth and good transparency.

2.Low fuzz ,dirt ,impurity and other stain

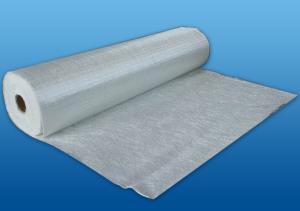

Images of E-glass Chopped Strand Mat

E-Glass Chopped Strand Mat Specification:

Property | Glass type | Weight(g/m2) | Width 200~3300 | Roll Weight | Moisture Content /% | Combustible Content /% | Breakage Strength /N |

Test Method | GB/T 1549 | ISO3374:2000 | ISO3374 | GB/T17470-1998 | ISO3344:1997 | ISO1887:1995 | ISO3342 |

EMC 80 | E-GLASS | 80±16 | ±5 | 6~50 | <0.2 | 13.6±0.35 | ≥200 |

EMC 100 | E-GLASS | 100±10 | ±5 | 6~65 | <0.2 | 9.5±0.35 | ≥170 |

EMC 150 | E-GLASS | 150±15 | ±5 | 6~97 | <0.2 | 8.0±0.35 | ≥40 |

EMC 225 | E-GLASS | 225±22 | ±5 | 6~150 | <0.2 | 5.0±0.6 | ≥60 |

EMC 300 | E-GLASS | 300±30 | ±5 | 6~180 | <0.2 | 4.0±0.6 | ≥90 |

EMC 450 | E-GLASS | 450±45 | ±5 | 6~180 | <0.2 | 3.8±0.6 | ≥120 |

EMC 600 | E-GLASS | 600±60 | ±5 | 6~240 | <0.2 | 3.6±0.6 | ≥150 |

EMC 900 | E-GLASS | 900±90 | ±5 | 6~190 | <0.2 | 3.4±0.6 | ≥180 |

FAQ of Chopped strand mat

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

- Q: How is fiberglass mat tissue used in the production of sports equipment?

- Fiberglass mat tissue is widely used in the production of sports equipment due to its unique properties and advantages. This material is a non-woven fabric made from fine glass fibers bonded together with a binder. It has a smooth texture and is lightweight, yet strong and durable. In the production of sports equipment, fiberglass mat tissue is typically used as a reinforcing layer. It helps to enhance the strength and rigidity of the final product, making it more resistant to impact and stress. This is particularly important in sports equipment where durability and performance are crucial, such as in the manufacturing of surfboards, skateboards, snowboards, and tennis rackets. When constructing a surfboard, for example, fiberglass mat tissue is commonly layered over a foam core and then impregnated with epoxy resin. This combination creates a strong and lightweight structure that can withstand the forces exerted by the waves. Similarly, in snowboards and skateboards, fiberglass mat tissue is applied to the wooden core to provide additional strength and stiffness, allowing for better control and responsiveness. Moreover, fiberglass mat tissue is also used in the manufacturing of protective gear like helmets and shin guards. By incorporating this material into the production process, these items can be made more impact resistant and capable of absorbing shocks. This is vital in sports where there is a high risk of injury, as the fiberglass mat tissue acts as a protective layer, dispersing and reducing the force of impacts. Overall, fiberglass mat tissue plays a crucial role in the production of sports equipment by reinforcing structures, enhancing strength and durability, and improving performance. Its lightweight nature combined with its superior mechanical properties makes it an ideal choice for various sporting applications, ensuring athletes can rely on their equipment to perform at their best while minimizing the risk of injury.

- Q: Can fiberglass mat tissue be used for ceiling insulation?

- Ceiling insulation requires specific materials that are more suitable and effective, such as fiberglass batts, cellulose, or foam insulation. These materials are designed to provide thermal resistance and reduce heat transfer between the interior and exterior of a building. Using fiberglass mat tissue for ceiling insulation is not recommended as it is not designed for insulation purposes. It is commonly used in construction applications like reinforcing plaster or other building materials, but it lacks the necessary thickness to effectively insulate ceilings. In addition, fiberglass insulation materials can pose safety risks as they release airborne particles and fibers that can be harmful if inhaled. Therefore, it is crucial to use insulation materials specifically engineered for ceiling insulation to ensure energy efficiency, comfort, and safety in your home or building.

- Q: Is fiberglass mat tissue suitable for insulation in chemical processing plants?

- Yes, fiberglass mat tissue is suitable for insulation in chemical processing plants. It is highly resistant to corrosion and chemicals, making it an ideal choice for such environments. Additionally, fiberglass mat tissue offers excellent thermal insulation properties, helping to maintain optimal temperature levels in the plant.

- Q: What is the specific gravity of fiberglass mat tissue?

- The specific gravity of fiberglass mat tissue can vary depending on the specific composition and manufacturing process. However, generally speaking, fiberglass mat tissue typically has a specific gravity ranging from 1.8 to 2.2. Specific gravity is a measurement that compares the density of a substance to the density of a reference substance, usually water. A specific gravity of 1.0 indicates that the substance has the same density as water, while a value greater than 1.0 indicates a higher density. Therefore, the specific gravity of fiberglass mat tissue suggests that it is denser than water.

- Q: Can fiberglass mat tissue be used for roofing?

- Yes, fiberglass mat tissue can be used for roofing. Fiberglass mat tissue is a type of material that is commonly used in the construction industry for various purposes, including roofing. It is known for its durability, strength, and ability to withstand harsh weather conditions. Fiberglass mat tissue is often used as a reinforcement layer in roofing systems, providing additional strength and stability to the roof. It helps to improve the overall performance and longevity of the roof by offering excellent resistance to water, fire, and other external factors. Additionally, fiberglass mat tissue is lightweight and flexible, making it easier to handle and install on roofs of different shapes and sizes. Overall, fiberglass mat tissue is a suitable choice for roofing applications due to its superior properties and performance.

- Q: Can fiberglass mat tissue be used for automotive repairs?

- Automotive repairs can indeed utilize fiberglass mat tissue. This versatile material finds its application across various industries, including the automotive sector. It serves to reinforce and mend auto body panels, while also addressing cracks, holes, and other damages that may afflict the vehicle's body. Comprised of resilient fibers held together by a resin, fiberglass mat tissue boasts exceptional strength and flexibility. As a result, it proves to be an ideal choice for automotive repairs. Its malleability allows it to conform to different contours and shapes of car parts, ensuring a seamless and precise restoration. Moreover, fiberglass mat tissue possesses the desirable qualities of being lightweight and durable, both of which are vital attributes for automotive repairs. It offers unparalleled resistance against corrosion, weathering, and other external elements, thereby guaranteeing the longevity of the repair. Additionally, it provides reliable impact resistance, effectively safeguarding the repaired area from further harm. Furthermore, fiberglass mat tissue harmonizes effortlessly with a wide range of automotive coatings, including primers, paints, and clear coats. This compatibility ensures a flawlessly smooth and professional finish once the repair work is completed. To summarize, fiberglass mat tissue stands as an appropriate choice for automotive repairs due to its formidable strength, flexibility, durability, and compatibility with automotive coatings. It is commonly employed in the industry to reinforce and mend auto body panels, address damages, and achieve an impeccable finish.

- Q: Does fiberglass mat tissue provide good fire protection?

- No, fiberglass mat tissue does not provide good fire protection.

- Q: How is fiberglass mat tissue used in the production of water tanks?

- Fiberglass mat tissue, which is made from glass fibers and falls under the category of non-woven fabric, is widely utilized in the manufacturing of water tanks due to its exceptional strength, durability, and resistance to corrosion. Typically, water tanks are constructed using fiberglass reinforced plastic (FRP), a composite material comprising a polymer matrix with fiberglass reinforcement. In this process, the fiberglass mat tissue plays a vital role as the material for reinforcement. To begin, the fiberglass mat tissue is cut into the desired shape and size to fit the mold of the water tank. It is then applied in layers onto the mold, with the number of layers determined by the required strength and thickness of the tank. Once in place, a resin matrix is used to impregnate and bind the fibers of the fiberglass mat tissue together. The specific resin employed, whether polyester, vinyl ester, or epoxy, depends on the particular requirements of the water tank. Typically, the resin is applied by either spraying or using a roller, ensuring complete saturation of the fiberglass mat tissue. This process is often repeated multiple times to achieve the desired thickness and strength of the tank. After the resin has cured, the fiberglass mat tissue and resin composite become rigid, forming the structure of the water tank. The resulting FRP tank is lightweight yet remarkably strong and durable, making it an excellent choice for water storage and transportation. The use of fiberglass mat tissue in water tank production offers several advantages. Firstly, it enhances the structural integrity of the tank, enabling it to withstand external forces such as pressure and impact. Secondly, fiberglass exhibits a high resistance to corrosion, ensuring that the tank remains in optimal condition even when exposed to harsh environmental conditions or corrosive substances present in the water. In conclusion, fiberglass mat tissue is an essential element in the production of water tanks, providing strength, durability, and corrosion resistance. This makes it a reliable option for various industrial, commercial, and residential applications.

- Q: Is fiberglass mat tissue suitable for railway rolling stock?

- Yes, fiberglass mat tissue is suitable for railway rolling stock. It offers excellent strength, durability, and fire resistance properties, making it a suitable material for various applications in the railway industry. Additionally, fiberglass mat tissue is lightweight, corrosion-resistant, and can be easily molded and shaped according to specific design requirements, making it an ideal choice for railway rolling stock components.

- Q: What are the advantages of using fiberglass mat tissue in construction?

- There are several advantages to using fiberglass mat tissue in construction. Firstly, fiberglass mat tissue provides excellent reinforcement and strength to various construction materials. It enhances the structural integrity and durability of the final product, making it resistant to cracks, impacts, and weathering. This makes fiberglass mat tissue an ideal choice for reinforcing concrete, roofing materials, and composite products. Secondly, fiberglass mat tissue is lightweight and easy to handle, making it convenient to work with during construction. Unlike traditional reinforcement materials like steel, which can be heavy and require specialized tools for installation, fiberglass mat tissue is easily cut, shaped, and applied. This reduces the labor and time required for construction, leading to cost savings. Additionally, fiberglass mat tissue is non-corrosive and non-conductive, making it suitable for use in a wide range of environments. It does not rust or degrade over time, even in harsh conditions, ensuring the longevity and reliability of the construction. Moreover, fiberglass mat tissue does not conduct electricity, making it a safe choice for applications where electrical conductivity needs to be avoided. Furthermore, fiberglass mat tissue offers excellent thermal insulation properties. It acts as a barrier to heat transfer, helping to maintain a comfortable and energy-efficient interior environment. This can lead to reduced heating and cooling costs in buildings, making fiberglass mat tissue a sustainable and cost-effective option. Lastly, fiberglass mat tissue is resistant to fire and chemicals. It does not burn or release toxic fumes when exposed to flames, providing an added level of safety in construction. Additionally, it is resistant to many chemicals, including acids and alkalis, making it suitable for use in corrosive environments such as chemical plants or industrial facilities. Overall, the advantages of using fiberglass mat tissue in construction include enhanced reinforcement, lightweight and easy handling, non-corrosive and non-conductive properties, thermal insulation, fire resistance, and chemical resistance. These benefits make it a versatile and reliable material for various construction applications.

Send your message to us

Fiberglass Mat Tissue from Italy Supplier - Fiberglass Unidirectional Fabric 350gsm 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords