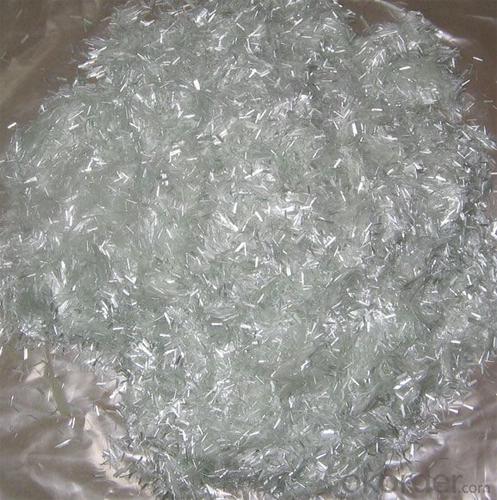

Fiberglass Mat Tissue E-Glass Fiber Chopped Strands for Thermoplastic

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction

Chopped strand mat is a non-woven reinforced material. It is manufactured by spreading continuous filament roving of 50mm in length, distributed it at random uniformly held together with powder or emulsion binder.

Product Features:

Uniform thickness, softness and hardness good.

Good compatibility with resin, easy completely wet-out.

Fast and consistent wet-out speed in resins and good manufacturability.

Good mechanical properties, easy cutting.

Good cover mold, suitable for modeling complex shapes.

Product Specifications:

Property | Fibre diameter | Moisture Content | Size Content | Chop |

(%) | (%) | (%) | (%) | |

Mathods | IS01888 | ISO3344 | ISO1887 | |

3mm | ±10 | ≤3.0 | 0.1±0.05 | 98 |

6mm | ||||

9mm | ||||

12mm |

Special specification can be produce according to customer requirements.

Packaging:

Each bag can be taken (15-25kgs)。 Could also take a big container bag.

Storage:

No special requirements in the case of chopped strand mat should be placed in a dry, cool damp-proof place. It should always be remained in the original packaging before and after use. The best storage temperature is between15 ℃ to 35 ℃, relative humidity of 35% -65%

- Q: How does the cost of fiberglass mat tissue compare to other reinforcement materials?

- The cost of fiberglass mat tissue is generally lower compared to other reinforcement materials such as carbon fiber or Kevlar.

- Q: How does fiberglass mat tissue perform in terms of moisture absorption?

- Fiberglass mat tissue performs exceptionally well in terms of moisture absorption. Due to its composition of multiple layers of glass fibers and a binder, it can effectively resist moisture penetration, making it highly resistant to water absorption. This property makes fiberglass mat tissue an ideal material for various applications where moisture resistance is crucial, such as in roofing, insulation, and composite manufacturing.

- Q: Can fiberglass mat tissue be used for making lightweight countertops?

- Yes, fiberglass mat tissue can be used for making lightweight countertops.

- Q: How does the roll weight of fiberglass mat tissue affect its transportation?

- The roll weight of fiberglass mat tissue directly affects its transportation in terms of the ease and cost. Heavier rolls will require more effort and resources for handling, loading, and unloading. They may also require specialized equipment for transportation, leading to higher shipping costs. On the other hand, lighter rolls are easier to handle and transport, reducing the overall logistical challenges and expenses.

- Q: Does fiberglass mat tissue require any special treatment for UV resistance?

- Yes, fiberglass mat tissue does require special treatment for UV resistance. Fiberglass mat tissue is typically made up of fine strands of glass fibers, which can be susceptible to damage from prolonged exposure to ultraviolet (UV) radiation. UV rays can cause the fibers to degrade, leading to a loss in strength and dimensional stability. To enhance the UV resistance of fiberglass mat tissue, manufacturers often apply a special coating or treatment to the material. This treatment helps to protect the fibers from UV radiation and prevent their degradation. The specific treatment used can vary depending on the intended application and the desired level of UV resistance. Additionally, it is important to note that even with special treatment, fiberglass mat tissue may still be subject to some level of UV damage over time. Therefore, it is recommended to minimize prolonged exposure to direct sunlight whenever possible to ensure the longevity and performance of the material.

- Q: Is fiberglass mat tissue resistant to termites and insects?

- Yes, fiberglass mat tissue is generally resistant to termites and insects. Fiberglass is made from woven glass fibers, which are not a food source for termites or insects. Additionally, fiberglass mat tissue is typically coated with a layer of resin, which further enhances its resistance to pests. This makes fiberglass mat tissue a popular choice for construction and insulation applications in areas prone to termite and insect infestations. However, it is worth noting that while fiberglass mat tissue itself is resistant to termites and insects, it does not guarantee complete protection against infestations. It is always advisable to take additional measures, such as proper sealing and regular inspections, to ensure long-term pest control.

- Q: Can fiberglass mat tissue be used for electrical enclosures?

- No, fiberglass mat tissue is not typically used for electrical enclosures. Electrical enclosures are designed to protect electrical equipment from outside elements like dust, moisture, and physical damage. They are usually made from materials that provide insulation and have high mechanical strength, such as sheet metal, plastic, or fiberglass reinforced plastic (FRP). While fiberglass mat tissue can provide some level of mechanical strength and insulation, it is not commonly used as the primary material for electrical enclosures due to its limited durability and lower resistance to moisture and impact.

- Q: How is fiberglass mat tissue used in the production of chemical storage tanks?

- Fiberglass mat tissue is utilized in the production of chemical storage tanks as a reinforcement material. It is typically combined with resin to form a composite material that provides strength, durability, and resistance to various chemicals. The fiberglass mat tissue is layered within the tank structure to enhance its structural integrity and prevent leakage. During the manufacturing process, the fiberglass mat tissue is impregnated with resin, usually polyester or epoxy, to create a strong bond between the fibers and the matrix. This impregnated mat is then placed on a mold or mandrel and subsequently covered with additional layers of resin and mat, forming a laminate. The number of layers and thickness can vary depending on the desired tank specifications and the chemicals it will store. The combination of the fiberglass mat tissue and resin provides excellent corrosion resistance, making it suitable for storing a wide range of chemicals. Fiberglass is inherently non-reactive and can withstand exposure to harsh chemicals, acids, and alkalis without degrading or compromising the tank's structural integrity. This makes fiberglass mat tissue a preferred material for chemical storage tanks, as it ensures the safety of the stored chemicals and minimizes the risk of leaks or contamination. Additionally, the use of fiberglass mat tissue allows for the production of tanks with complex shapes and sizes, as it can be easily molded and formed into various configurations. This flexibility in design ensures that chemical storage tanks can be tailored to specific requirements and can be efficiently integrated into different industrial applications. In summary, fiberglass mat tissue plays a crucial role in the production of chemical storage tanks by reinforcing the tank structure, providing resistance to chemicals, and enabling the fabrication of tanks with diverse shapes and sizes. Its combination with resin creates a durable and corrosion-resistant composite material, ensuring the safe storage of chemicals in various industrial settings.

- Q: Can fiberglass mat tissue be used for repairing automotive parts?

- Yes, fiberglass mat tissue can be used for repairing automotive parts. It is commonly used in automotive repairs as it provides strength and durability to the repaired area. The mat tissue can be applied with resin to reinforce damaged or weakened sections of automotive parts, making it an effective solution for repairing various components.

- Q: Is fiberglass mat tissue suitable for aerospace repairs?

- Indeed, fiberglass mat tissue proves to be a fitting choice for aerospace repairs. This lightweight and pliable material can be effortlessly shaped and applied to various surfaces. Its exceptional strength-to-weight ratio makes it particularly suitable for circumstances where weight plays a crucial role, such as aerospace repairs. Aerospace repairs frequently employ fiberglass mat tissue to fortify areas of the aircraft structure that have been compromised or weakened. By doing so, it ensures outstanding structural integrity and longevity, enabling the repaired region to endure the demanding conditions and stresses encountered during flight. Moreover, fiberglass mat tissue demonstrates compatibility with various resin systems, including epoxy and polyester. This allows for efficient bonding, guaranteeing a dependable repair. Its versatility permits it to be utilized in both interior and exterior repairs, such as patching up composite panels, reinforcing wing sections, or rectifying damaged fuselage areas. Beyond its mechanical attributes, fiberglass mat tissue also exhibits exceptional resistance to corrosion, moisture, and chemicals. This enhances the durability of the repaired components, a particularly important feature in aerospace applications where the aircraft is frequently exposed to harsh environmental conditions. All in all, fiberglass mat tissue emerges as a suitable material for aerospace repairs due to its lightweight nature, impressive strength, versatility, and resistance to environmental factors. Its use in the aerospace industry has been firmly established, and it remains a dependable choice for repairing and reinforcing critical aircraft components.

Send your message to us

Fiberglass Mat Tissue E-Glass Fiber Chopped Strands for Thermoplastic

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords