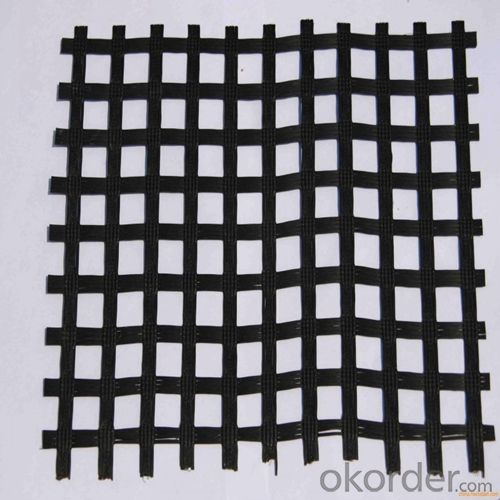

Non Woven Geotextile Fabric for Fiberglass Geogrid in Mining and Tunnel Reinforcement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description

Geogrid allows assembling within the temperature range from -40°C to +60°C. The material is neutral to aggressive environments and ecologically safe. Laying does not require additional machinery. In fold position geogrid does not take much place.

Type:

Geogrids

Place of Origin:

Anhui, China (Mainland)

Brand Name:

CMAX

Model Number:

Biaxial

Material:

Fiberglass

Tensile strength:

100kn

Production function

1.It can be applied in all kinds of roads,airports to enhance the roadbed;

2.It can be applied in a large car park and terminal freight yard,etc. to strengthen the foundations of a permanent load;

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Geotextile water filter?

- Will the geotextile is mainly to strengthen the role of water conservation

- Q: Can geotextiles be used in coastal dune stabilization projects?

- Yes, geotextiles can be used in coastal dune stabilization projects. Geotextiles are commonly used in such projects to create barriers that help prevent erosion, promote vegetation growth, and provide stabilization to the dune system. They can effectively control sand movement, prevent sand loss, and enhance the stability and resilience of coastal dunes.

- Q: Can geotextiles be used in landfill construction?

- Yes, geotextiles can be used in landfill construction. They are often used as a barrier or liner material to separate the waste from the underlying soil and prevent leachate from contaminating the surrounding environment. Geotextiles can also be used to reinforce the landfill slopes and prevent erosion.

- Q: Can geotextiles be used in the protection of retaining walls?

- Yes, geotextiles can be used in the protection of retaining walls. Geotextiles are commonly used as a barrier against soil erosion and to reinforce the soil behind retaining walls. They help to prevent the loss of backfill material and provide stability and strength to the structure.

- Q: How do geotextiles affect soil consolidation?

- Geotextiles have a positive impact on soil consolidation as they provide reinforcement and stabilization. By acting as a barrier, they prevent the mixing of different soil layers, reducing the potential for settlement and increasing the overall strength of the soil. This consolidation is achieved through the interlocking of geotextile fibers with the soil particles, enhancing the load-bearing capacity and preventing the loss of fine particles.

- Q: What are the key considerations for geotextile installation in areas prone to landslides?

- The key considerations for geotextile installation in areas prone to landslides include understanding the slope stability and soil characteristics, selecting the appropriate type and strength of geotextile, ensuring proper anchoring and connection methods, implementing effective drainage systems, and regularly monitoring and maintaining the geotextile system.

- Q: Can geotextiles be used in the construction of sports fields?

- Yes, geotextiles can be used in the construction of sports fields. Geotextiles are commonly used as a separation and drainage layer under the playing surface to prevent soil contamination, promote proper water drainage, and enhance the stability and longevity of the field. Additionally, geotextiles can help control erosion and provide reinforcement to the subgrade, ensuring a durable and high-quality sports field.

- Q: Filament non-woven geotextile, geomembrane, how much need to use third-party testing?

- This depends on the party and the supervision requirements, and generally 1-2 million square a test batch, I am specializing in the production of geotechnical materials

- Q: Can geotextiles be used in shoreline restoration projects?

- Yes, geotextiles can be used in shoreline restoration projects. Geotextiles are commonly used to stabilize and protect soils in various engineering applications. In shoreline restoration, they can help control erosion, stabilize slopes, promote vegetation growth, and protect against wave action.

- Q: Geotextile use

- Geotextile is a new type of building materials, raw materials are polyester, acrylic, nylon and other polymer polymer synthetic fiber. In accordance with the manufacturing method is divided into: there are two types of geotextile and non-woven geotextile. Geotextile with anti-seepage, anti-filtration, drainage, isolation, reinforcement, protection, sealing and other functions, it with the conventional masonry and concrete material seepage effect compared to a low investment, simple construction process, short duration Infiltration effect is good, the channel effective use of high coefficient. Water conservancy engineering dams and slope protection filter, channel isolation, seepage control; road, railway, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, drainage; , Geotextile has been widely used in the field of infrastructure construction, and has been gradually applied in the field of infrastructure construction, and the use of geotextile In a wider area.

Send your message to us

Non Woven Geotextile Fabric for Fiberglass Geogrid in Mining and Tunnel Reinforcement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords