Fiberglass Direct Roving for Water Tanks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Direct Roving for Water Tanks

Introduction:

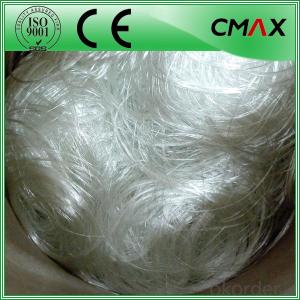

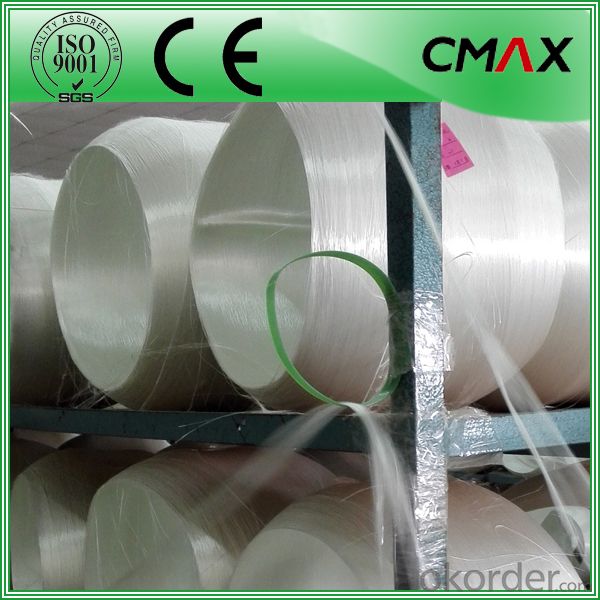

Direct Roving is coated with a silane-based sizing and compatible with unsaturated resin, vinyl resin, and epoxy resin. It is designed for filament winding, pultrusion, and weaving applications.

Direct Roving is suitable for use in pipes, pressure vessels, gratings, and profiles, and the woven roving converted from it is used in boats and chemical storage tanks.

Product Features:

1.Resistant to ozone, oxygen, light and climate change.

2.High strength, high modulus, low shrink, no deformation.

3.Incombustible. heat insulation, heat preservation.

4.Hgher than working temperature, still keep residual strength.

5.Corrosion resistance.

6.Electrical insulation.

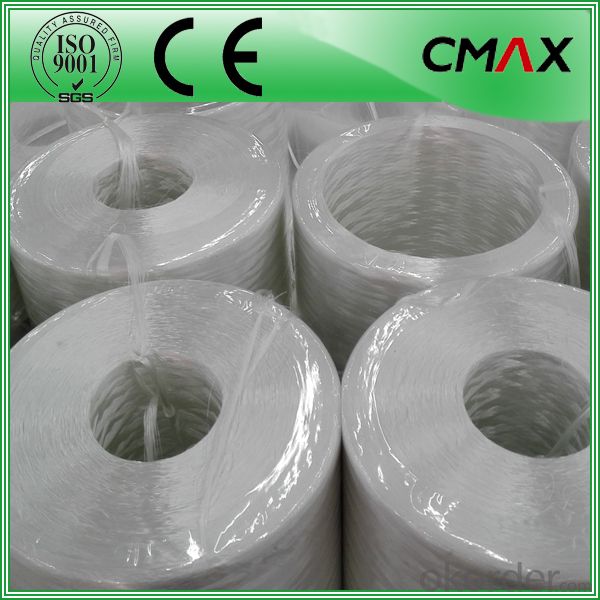

Packaging:

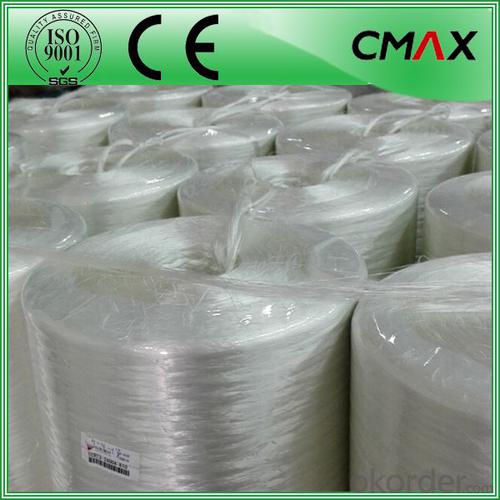

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: Can fiberglass mat tissue be used for windbreak panels?

- Yes, fiberglass mat tissue can be used for windbreak panels. It is a lightweight and durable material that can provide effective protection against wind and other environmental elements.

- Q: Is fiberglass mat tissue easy to install?

- Installing fiberglass mat tissue is relatively easy. This lightweight and flexible material can be easily cut and shaped to fit any surface. It can be applied using different methods, including spraying, rolling, or brushing on adhesive. Moreover, the tissue is self-adhesive, which simplifies the installation process as it readily adheres to the desired surface. Additionally, fiberglass mat tissues are generally designed to resist water and offer excellent insulation, making them a favored choice for various applications. In conclusion, by adequately preparing and following the manufacturer's guidelines, installing fiberglass mat tissue can be a simple and trouble-free task.

- Q: Is fiberglass mat tissue compatible with different resin systems?

- Yes, fiberglass mat tissue is compatible with different resin systems. Fiberglass mat tissue is a versatile material that can be used with various types of resin systems, including polyester, epoxy, and vinyl ester resins. It has excellent wet-out properties, meaning that it can easily absorb and distribute the resin evenly throughout the mat. This compatibility allows for the creation of strong and durable composite structures in a wide range of applications such as automotive, marine, construction, and aerospace industries. However, it is important to consider the specific properties and characteristics of the resin system being used in order to ensure optimal performance and compatibility with the fiberglass mat tissue.

- Q: Can fiberglass mat tissue be used for repairing fiberglass shower stalls?

- Yes, fiberglass mat tissue can be used for repairing fiberglass shower stalls. It is a commonly used material for reinforcing and repairing fiberglass surfaces, including shower stalls.

- Q: What is the maximum temperature resistance of fiberglass mat tissue?

- The maximum temperature resistance of fiberglass mat tissue typically ranges between 300-600 degrees Celsius, depending on the specific composition and quality of the material.

- Q: How does fiberglass mat tissue compare to polystyrene insulation?

- Fiberglass mat tissue and polystyrene insulation are two different materials used for insulation purposes, and they have their own distinct characteristics and benefits. Fiberglass mat tissue is made from thin strands of glass fibers that are woven together to form a mat. It is commonly used in applications where heat and sound insulation is required. Fiberglass mat tissue is known for its excellent thermal insulation properties, as it can effectively resist heat transfer, making it suitable for both hot and cold environments. Additionally, it is resistant to moisture and does not promote the growth of mold or mildew. On the other hand, polystyrene insulation is a foam material made from expanded polystyrene beads. It is widely used in the construction industry as it provides good thermal insulation and can be easily shaped or cut to fit various spaces. Polystyrene insulation is known for its high compressive strength, making it ideal for load-bearing applications. It is also moisture-resistant, lightweight, and has excellent resistance to aging and degradation. When comparing fiberglass mat tissue to polystyrene insulation, there are a few key differences to consider. Fiberglass mat tissue is generally more flexible and can be easier to install in irregular or curved surfaces. It is also more resistant to fire, as it does not burn or release toxic gases when exposed to flames. However, fiberglass mat tissue can be more expensive than polystyrene insulation and may require additional protective measures, such as wearing gloves and masks during installation, due to its potential for skin and respiratory irritation. Polystyrene insulation, on the other hand, is less expensive and easier to handle and install compared to fiberglass mat tissue. It also has better moisture resistance, which makes it suitable for applications in areas with high humidity or potential water exposure. However, polystyrene insulation is more flammable than fiberglass mat tissue and can release toxic gases when burned. In conclusion, the choice between fiberglass mat tissue and polystyrene insulation depends on the specific requirements of the insulation project. Fiberglass mat tissue is well-suited for its excellent thermal insulation properties, fire resistance, and resistance to moisture and mold. Polystyrene insulation, on the other hand, offers good thermal insulation, ease of installation, and high compressive strength. Ultimately, it is important to consider factors such as cost, installation requirements, fire resistance, and moisture resistance when deciding between fiberglass mat tissue and polystyrene insulation.

- Q: What are the properties of fiberglass mat tissue?

- Fiberglass mat tissue, also referred to as fiberglass mat or fiberglass matting, is a non-woven material made from glass fibers, possessing numerous properties that render it suitable for diverse applications. 1. With regards to strength and durability, fiberglass mat tissue is renowned for its high tensile strength, enabling it to endure substantial stress without fracturing. This quality makes it ideal for fortifying and reinforcing various materials and structures. 2. Despite its strength, fiberglass mat tissue remains relatively lightweight, facilitating easy handling and transportation. This characteristic proves particularly advantageous in industries where weight reduction plays a crucial role, such as aerospace and automotive. 3. The flexibility of fiberglass mat tissue allows it to conform to curved surfaces and intricate shapes. Consequently, it proves versatile and appropriate for applications requiring the material to be molded or shaped into specific designs. 4. Fiberglass mat tissue exhibits excellent resistance to various chemicals, including acids, alkalis, and most solvents. This attribute renders it suitable for use in corrosive environments, such as chemical processing plants or storage tanks. 5. Fiberglass mat tissue possesses commendable thermal insulation properties, effectively reducing heat transfer. Consequently, it proves valuable in applications necessitating heat insulation, such as the construction of walls, roofs, or insulation boards. 6. Inherently fire-resistant, fiberglass mat tissue does not contribute to the propagation of flames. As a result, it finds extensive use in applications where fire safety is paramount, such as the production of fire-resistant doors, panels, or insulation materials. 7. Furthermore, fiberglass mat tissue offers excellent sound insulation properties, diminishing the transmission of noise through walls or other structures. This characteristic renders it suitable for implementation in soundproofing applications, such as recording studios or automotive interior panels. Overall, the properties exhibited by fiberglass mat tissue endow it with versatility, allowing for a wide range of applications across various industries, including construction, automotive, aerospace, and marine. Its strength, flexibility, lightweight nature, chemical resistance, thermal and sound insulation properties, as well as its fire resistance, contribute to its popularity and usefulness in numerous applications.

- Q: Does fiberglass mat tissue require any special tools for installation?

- Special tools may be needed for installing fiberglass mat tissue. These tools may include a utility knife or scissors for cutting the mat to the desired size, a roller or brush for applying adhesive or resin to secure the mat to the desired surface, and safety equipment like gloves and goggles to protect the installer from potential dangers. Furthermore, certain installations may necessitate the use of a heat gun or torch to activate or cure the resin. To ensure proper installation and ascertain if any special tools are necessary, it is crucial to carefully read and adhere to the manufacturer's instructions and recommendations for the specific fiberglass mat tissue being used.

- Q: What are the typical roll sizes available for fiberglass mat tissue?

- The manufacturer and specific application determine the varying sizes of fiberglass mat tissue rolls. Generally, they range in width from 50 inches to 120 inches and in length from 100 yards to 1,000 yards. These sizes are frequently utilized in construction, automotive, and marine industries for purposes such as insulation, reinforcement, and soundproofing. It should be emphasized that the availability of particular roll sizes may vary depending on the supplier and the intended use of the fiberglass mat tissue.

- Q: Can fiberglass mat tissue be used for making lightweight partitions?

- The utilization of fiberglass mat tissue is applicable for the creation of lightweight partitions. As a lightweight material composed of delicate glass fibers, fiberglass mat tissue is acknowledged for its robustness, resilience, and flexibility, rendering it an appropriate option for partition construction. When employed in partition production, fiberglass mat tissue can be sandwiched between other lightweight substances like gypsum boards or plywood to contribute supplementary strength and stability. Acting as a reinforcement layer, the fiberglass mat tissue thwarts cracks and augments the overall structural integrity of the partition. Moreover, fiberglass mat tissue possesses exemplary fire-resistant attributes, an indispensable aspect in partition construction. It aids in containing and impeding the spread of fire, thereby ensuring the occupants' safety. In addition to its strength and fire resistance, fiberglass mat tissue also exhibits exceptional sound insulation properties. Consequently, it effectively reduces noise transmission between different areas, making it the ideal material for generating private and tranquil spaces. All in all, fiberglass mat tissue is a fitting preference for producing lightweight partitions due to its strength, durability, fire resistance, and sound insulation properties. Consequently, it can be effectively employed in various applications such as residential edifices, offices, hotels, and other commercial spaces.

Send your message to us

Fiberglass Direct Roving for Water Tanks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords