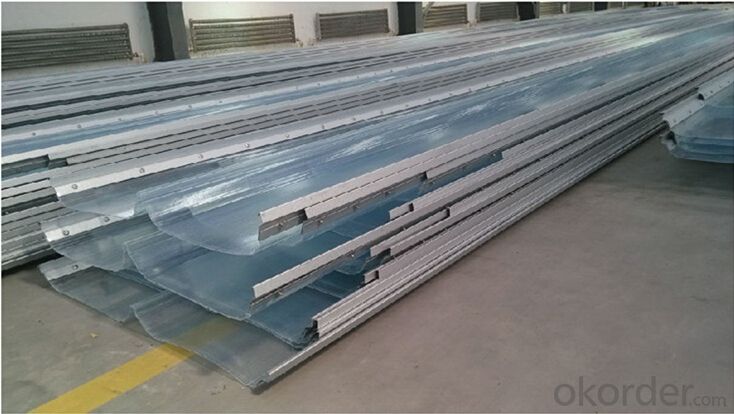

FRP Pultrusion Profiles - Fiber Reinforce Plastic Skylight Panel with Aluminum Edge

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

FRP Skylight Panel with Aluminum Edge

1. UV Resistance: 100%;

2. Light Transmittance: 3%-85%;

3. Fiber Content: 25% - 35%

Product Description

Specifications of FRP Skylight Panel with Aluminum Edge :

1. High Quality FRP plate

2. UV Protection

3. High strength, good light transmission

Technical date of FRP Plate

Density | 1.45 g/cm3 | Tensile strength | 75Mpa |

Fiber content | 25% - 35% | Bending strength | 125Mpa |

Curing degree | >82% | Impact ductility | 90 KJ/M2 |

Weathering film thickness | 20-30μm | Thermal conductivity | 0.158 W/m.k |

Light transmissivity | 3% - 85% | Thermal expansivity | 2.6x10-5mm/mm/°C |

Suitable temperature | -40~ +120 | UV Resistance | 100% |

Thickness of PRP plate:1.2mm ~1.8mm, tolerance ± 10%;

Thickness of coated steel tile: 0.5mm, the color should be consistent with the roof colorplate;

Thickness of aluminum zine plate: 0.5mm

Weidth:<1.1m, different width according to the profile

Length: Accordingto the demand

Color: Clear blue, Light blue, Lake blue, Sky blue, Deepblue, Clear white, Solid white, Gray white, Black, Clear green or Customizable

Product Types: Single layerskylight, insulation double layers skylight in normal

Features: Anti condensation, heatinsulation, noise insulation, good water tightness, ensure the roof structure,energy saving and environmental protection, 360 degree upright occlusion, goodappearance.

Match the coated steel tile, easy installation. According to differentcustomer needs to produce products that satisfy you!

Occlusion Types:

1. Single 360 degree of occlusion;

2. Double 360 degree of occlusion;

3. Single 180 degree of occlusion;

4. Double 180 degree of occlusion.

Advantages:

1. Vertical occlusion, avoid leakageand seepage;

2. Convenient installation;

3. Ensure the whole roof structure

4. Low cost maintenance;

5. Prevent condensation

6. Good sound insulation, heatinsulation, thermal preserve

Application : High demandelectronics factory, valuables storage workshop, high precision machine shop,cold regions need to heat insulation lighting workshop, etc.

- Q: What does M23 grade of glass fiber reinforced plastic section mean?

- Glass fiber reinforced plastic profiles are mainly used in the field: general and environmental units of manhole covers, factories and mines units of insulated cable tray; chemical units of the transmission pipeline; insulation protection fence; including floor and so on. More fields. Advantage is obvious, if the corrosion resistance, insulation resistance, quality is lighter than steel; strength and steel strength comparable.

- Q: Are FRP pultrusion profiles resistant to chemical spills or leaks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to chemical spills or leaks. The combination of the fiberglass reinforcement and the polymer matrix used in FRP pultrusion provides excellent resistance to a wide range of chemicals, acids, and corrosive substances. This makes FRP pultrusion profiles a suitable choice for applications where chemical resistance is crucial, such as in chemical processing plants, wastewater treatment facilities, and storage tanks.

- Q: Can FRP pultrusion profiles be used in agricultural structures?

- Agricultural structures can indeed utilize FRP pultrusion profiles. FRP pultrusion profiles, also known as Fiber Reinforced Polymer profiles, possess numerous advantages that render them suitable for agricultural purposes. To begin with, the corrosion resistance of FRP profiles is of utmost importance in the agricultural industry, given the exposure of structures to harsh environments and chemicals like fertilizers and pesticides. Unlike conventional materials such as steel or wood, FRP does not rust or decay, ensuring enduring performance in agricultural structures. Furthermore, FRP profiles are lightweight yet durable, facilitating easy handling and installation in agricultural applications. Their high strength-to-weight ratios enable efficient construction, thereby reducing the necessity for heavy machinery during the installation process. Moreover, FRP profiles exhibit exceptional mechanical properties, including high stiffness and impact resistance, which prove advantageous for agricultural structures subjected to heavy loads, vibrations, or machinery impact. In addition, FRP pultrusion profiles can be designed to resist UV radiation, thereby preventing degradation from prolonged exposure to sunlight. This quality makes them suitable for outdoor agricultural structures consistently exposed to the elements. Lastly, FRP profiles are non-conductive, a critical advantage in agricultural environments where electrical safety is paramount. This characteristic eliminates the risk of electrical hazards associated with conductive materials like steel. In summary, FRP pultrusion profiles offer a reliable and efficient solution for a variety of agricultural structures, such as greenhouse frames, livestock enclosures, irrigation systems, and storage facilities. Their corrosion resistance, lightweight nature, high strength, UV resistance, and non-conductivity make them an ideal choice for agricultural applications.

- Q: What are the circumstances in which the pultrusion should be performed?

- (1) the tensile strength of high strength extruded profiles for 150 ~ 300MPa, the bending strength reached 200 ~ 300MPa, the 1000h accelerated the bending strength after aging the retention rate of up to 78%.(2) the deformation rate is low. The length of the glass reinforced plastic pultruded section is accelerated by 1000h and the width change rate is +0.03%. The width change rate is -0.07%.. Therefore, the geometry and size of the product made of this pultruded section can be stable for a long time

- Q: What are the load-bearing capabilities of FRP pultrusion profiles?

- The load-bearing capabilities of FRP pultrusion profiles vary depending on the specific profile design and the type of reinforcement used. However, FRP pultrusion profiles are known to have high strength-to-weight ratios and can generally handle heavy loads. They are often used in structural applications where strength and durability are important factors.

- Q: Are FRP pultrusion profiles resistant to impact from flying debris?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength and durability. They are generally resistant to impact from flying debris due to their inherent properties. The combination of the reinforcing fibers, typically made of fiberglass, and the polymer matrix provides excellent impact resistance. The specific resistance to impact from flying debris can vary depending on the specific design, thickness, and composition of the FRP pultrusion profiles. However, in most cases, these profiles are designed to withstand impact forces and can effectively resist damage caused by flying debris. Furthermore, FRP pultrusion profiles are often used in applications where impact resistance is crucial, such as in construction, transportation, and infrastructure industries. These profiles have been tested and proven to withstand various impact scenarios, making them a reliable choice for applications where flying debris is a concern. It is important to note that while FRP pultrusion profiles offer good impact resistance, the severity of the impact and the velocity of the flying debris can still affect the level of damage. Therefore, it is advisable to consult with the manufacturer or engineer to ensure the specific FRP profile chosen is suitable for the intended application and potential impact conditions.

- Q: Can FRP pultrusion profiles be used in the construction of playground equipment?

- Yes, FRP pultrusion profiles can be used in the construction of playground equipment. FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength-to-weight ratio, durability, and resistance to corrosion and weathering. These qualities make them suitable for various applications, including playground equipment, where safety and longevity are important factors. FRP pultrusion profiles can be used to construct slides, climbing structures, handrails, and other components of playground equipment, providing a safe and reliable solution for recreational areas.

- Q: Can FRP pultrusion profiles be used in the construction of industrial flooring?

- Indeed, the utilization of FRP (Fiber Reinforced Polymer) pultrusion profiles is viable in the construction of industrial flooring. These profiles are comprised of a composite material, combining robust fibers (usually glass or carbon) with a polymer resin. This amalgamation of materials imparts exceptional strength, durability, and resistance to corrosion, rendering FRP profiles highly suitable for industrial flooring applications. The primary benefit of FRP pultrusion profiles lies in their remarkable strength-to-weight ratio. Consequently, they are lighter and more manageable compared to conventional materials like steel or concrete. Moreover, FRP profiles possess non-conductive and non-magnetic properties, offering advantages in specific industrial environments. FRP pultrusion profiles also exhibit high resistance to various chemicals, moisture, and UV radiation, making them an ideal choice for harsh and corrosive settings. Unlike steel, they do not rust or corrode, nor are they affected by moisture or rot like wood. As a result, they ensure long-lasting performance and necessitate minimal maintenance. Additionally, FRP profiles can be customized and manufactured in diverse shapes, sizes, and load-bearing capacities to meet specific industrial flooring requirements. They can be designed to withstand heavy loads, impact, vibration, and other dynamic forces commonly encountered in industrial settings. In conclusion, FRP pultrusion profiles offer numerous advantages that make them well-suited for the construction of industrial flooring. Their high strength, durability, corrosion resistance, and customizable nature make them a dependable and cost-effective choice for industrial flooring applications.

- Q: Can FRP pultrusion profiles be used in the construction of modular storage systems?

- Yes, FRP pultrusion profiles can be used in the construction of modular storage systems. FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages that make them suitable for such applications. Firstly, FRP pultrusion profiles are lightweight yet extremely strong and durable. This makes them ideal for modular storage systems where weight is a concern, as they can provide structural support without adding excessive load. Additionally, their high strength-to-weight ratio ensures that the storage systems can withstand heavy loads and provide long-lasting performance. Secondly, FRP pultrusion profiles are corrosion-resistant. This is a crucial characteristic for storage systems, especially those used in outdoor or harsh environments where exposure to moisture, chemicals, or extreme temperatures can lead to corrosion. By using FRP pultrusion profiles, the storage systems can be protected against corrosion, ensuring their longevity and reducing maintenance requirements. Furthermore, FRP pultrusion profiles can be easily customized to meet the specific requirements of modular storage systems. They can be designed in various shapes, sizes, and configurations, allowing for flexibility in the design and construction process. This makes it easier to create storage systems that fit specific spaces and accommodate different types of items. Lastly, FRP pultrusion profiles offer excellent electrical insulation properties. This can be particularly beneficial in storage systems where electrical components or sensitive materials need to be stored. The insulation provided by FRP pultrusion profiles helps protect against electrical hazards and ensures the safety of the stored items. In conclusion, FRP pultrusion profiles are a suitable material choice for the construction of modular storage systems. Their lightweight yet strong nature, corrosion resistance, customization possibilities, and electrical insulation properties make them a reliable and efficient solution for this application.

- Q: Can FRP pultrusion profiles be used in the construction of agricultural structures?

- FRP pultrusion profiles have the capability to be utilized in the construction of agricultural structures. They possess various advantages that make them appropriate for agricultural applications. To begin with, FRP pultrusion profiles are both lightweight and strong, making them well-suited for the creation of agricultural structures such as greenhouses, barns, and storage facilities. Their high strength-to-weight ratio enables easy installation and reduces the overall weight of the structure, thus minimizing the need for heavy machinery during construction. Furthermore, FRP pultrusion profiles have the benefit of being corrosion-resistant. This is a critical characteristic for agricultural structures that are exposed to diverse environmental elements like moisture, chemicals, and fertilizers. Unlike traditional materials like wood or steel, FRP does not rot, rust, or corrode, ensuring the longevity and durability of the agricultural structure. Additionally, FRP pultrusion profiles possess excellent electrical insulation properties. This is particularly advantageous in agricultural applications where electrical equipment, such as lighting systems or ventilation controls, are commonly employed. The non-conductive nature of FRP eliminates the risk of electrical shocks or short circuits. Moreover, FRP pultrusion profiles are highly customizable and can be tailored to meet specific requirements. This adaptability allows for the creation of structures that are customized to the unique needs of agricultural operations, such as load-bearing capacity, dimensional accuracy, and thermal insulation. Furthermore, FRP pultrusion profiles are non-magnetic, which makes them suitable for use in agricultural structures where magnetic interference can disrupt sensitive equipment or affect crop growth. In conclusion, the utilization of FRP pultrusion profiles in the construction of agricultural structures provides numerous benefits, including lightweight construction, corrosion resistance, electrical insulation, customization options, and non-magnetic properties. These advantages establish FRP pultrusion profiles as a viable and practical choice for agricultural applications.

Send your message to us

FRP Pultrusion Profiles - Fiber Reinforce Plastic Skylight Panel with Aluminum Edge

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords