FeSi 72%&75% With Chinese Origin Export

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

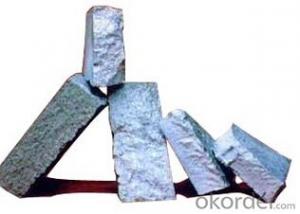

Ferro Silicon 72% & 75%.It is used extensively in the steel-making, casting non-ferrous metals and other industrial production.I

1, Features:

The appearance of Ferro Silicon is the grey lumpish solid. It has very strong stabilities and does not place any chemical reaction in the dry air.

2, Application:

It is used extensively in the steel-making, casting non-ferrous metals and other industrial production.It is the good deoxidizer and most steel kind use the Ferro Silicon for deoxidization;

In steel smelting, it is used to sedimentary accretion and expanding deoxidizing.It is used to prove the strength, hardness and elasticity of steel greatly in steel casting.

Grade | Chemicals Composition(%) | ||||

Si | Al | C | S | P | |

%(min) | %(max) | ||||

FeSi 75% FeSi 75% FeSi 72% | 75 | 0.5-1.0 | 0.15 | 0.02 | 0.04 |

75 | 1.5-2.0 | 0.20 | 0.02 | 0.04 | |

72 | 1.5-2.0 | 0.20 | 0.02 | 0.04 | |

FeSi 70% | 70 | 1.5-2.0 | 0.20 | 0.02 | 0.04 |

Lump size | 10-50 mm, 50-100 mm,10-100 mm, 50-150mm: 90%min, or at customer’s option; | ||||

Packing | In jumbo bag about 1MT/bag | ||||

FACTORY:

- Q: Y represents the metallurgical (Yejin) Department standard. W stands for universal (Wanneng) alloy

- Ha ha, I'm good at that!HC is the sign of the attractive magnetic force of the alloy, and HRA is the sign of hardness. COM is the cobalt magnetic mark of the alloy. D is the density of the alloy. The general quality certificate of the alloy product will have three indexes above

- Q: Which is better, cemented carbide, YG8 and YG20?

- YG8 contains about 8% cobalt, the hardness is higher than YG20, and the strength is lower than YG20,

- Q: What is hard alloy steel?

- Modern ultra hard alloys are produced by sintering of carbides of tungsten carbide and some other elements. It is the hard metal (tungsten, tantalum, titanium, molybdenum, etc.) carbide carbide particles, with one or several iron elements (cobalt, nickel or iron) powder mixed, pressed molding, and then made by sintering.Cemented carbide is the most powerful alloy in the world at present. Hard alloy widely used now has two main categories: the first is to do the cobalt WC alloy binder; the second is to make titanium carbide alloy tool steel binder.Cemented carbide is used as a tool, and its hardness will not decrease even at high temperatures of 1000 degrees. Therefore, for high speed cutting, cutting speed up to 2000 meters per minute, 100 times higher than the ordinary carbon steel cutter, tungsten steel cutter is 15 times higher than. The mold made of it can be punched about 3000000 times, which is 60 times longer than the ordinary alloy steel die.

- Q: What are the well-known brands of cemented carbide materials at home and abroad?

- A lot of foreign ah, Sweden Sandvik, German - Luxemburg, American Kenna, Israel - Domestic - hard line iscar; diamond, Zigong the Great Wall, Xiamen gol-egret etc.

- Q: How to tell what is hard alloy and what is high speed steel?

- Experiment with a magnet, carbide is not sucked, high-speed steel can suck.Hardness can be tested by marking plates or glass.

- Q: The difference between cemented carbide YG 15 and yg12

- Material introduction: YG3X 14.6-15.2 132092 is suitable for high speed finish machining of cast iron, non-ferrous metal and alloy, hardened steel, alloy steel and small cutting section. K01 YG3X YG6A 14.6-15.0 137091.5 is suitable for semi hard finishing of hard cast iron, non-ferrous metals and their alloys. It is also suitable for semi finishing and finishing of high manganese steel, quenched steel and alloy steel. K05 YG6A YG6X 14.6-15.0 142091 has been proved by the production and use that the alloy can be used to process chilled alloy cast iron and heat-resisting alloy steel. It can also achieve good results and is also suitable for the finishing of ordinary cast iron. K10 YG6X YK15 14.2-14.6 210091 is suitable for processing integral alloy drilling, milling, reaming and other cutting tools. It has high wear resistance and toughness. K15 K20 YK15 YG6 14.5-14.9 138089 is suitable for semi finishing with medium casting speed of cast iron, non-ferrous metals and alloys, non-metallic materials. K20 YG6 YG6X-1 14.6-15.0 150090 is suitable for cast iron, nonferrous metals and alloy non metal material during continuous cutting finishing, discontinuous cutting the semi refined car, fine car, small section fine car, coarse thread, continuous section semi finishing milling and finish milling, rough and fine hole expansion. K20 YG6X-1 YG8N 14.5-14.8 200090 is suitable for high speed cutting of cast iron, white cast iron, nodular cast iron, and chrome, nickel and stainless steel.

- Q: Several hard alloy cutter lathe with?

- YG car, pig iron and so on, YT, steel and the like, high temperature resistant, YW car alloy steel, the highest strength.

- Q: How are cemented carbides sintered?

- After cooling, the hardened phases are distributed in a grid of bonded metals that are closely related to each other and form a solid whole. The hardness of cemented carbide depends on the content of the hardened phase and grain size. The higher the content of the hardened phase and the finer the grain, the greater the hardness. The toughness of cemented carbide is determined by bonding metal. The higher the bonding metal content is, the greater the bending strength is.

- Q: What are the differences in performance between cemented carbide cutting tools and PCD cutters (polycrystalline diamond)?

- Different cutting objects, PCD cutter durable, but cutting some materials may not be good on the PCD

- Q: What are the types, codes, and range of application of cemented carbides?

- Many domestic brands, mainly diamond brand based, and now there are many new brands, YS/YL/YW/YG10X/YG6X/ many, if you need, I send a detailed table to you!

Send your message to us

FeSi 72%&75% With Chinese Origin Export

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords