High-Quality Ferro Silicon Raw Materials for Refractory Applications in South Korea

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ferro Silicon

Usage

Ferro silicon is widely used in the steel making,iron casting ,low-carbon ferroalloy producing:

1 In the steel making field,Ferro silicon is used as deoxidizer and alloying agent to precipit and diffusedeoxidation.Adding a certain amount silicon of fe-si to the steel can obviously improve the strength ,hardness ,elasticity and permeability of steel.

2 In the iron casting,it is used as ball mile agent and alloying agent especially in the nodular iron casting, Adding ferrosilicon to cast iron ,it can prevent the formation of carbide and promote the precipitation of graphite and the nodulizing.then the mechanical capacity can be the same of steel's.

3 High-silicon ferrosilicon can be used for the production of the low-carbon reductant in ferro alloy industry.

4 In addition ,ferro silicon powder can be used as a suspended phase in the mineral processing industry and coatings for welding electrodes in the electrode manufactruing.

Application

Used as deoxidants and desulfurizing agents, and could purity the molten steel, etc. The size includes:0-3mm, 3-25mm,10-50mm, etc.

Packaging & Delivery

Packing Details: In 1 MT Jumbo Bags

Delivery Detai | Within 30 days after received the deposite |

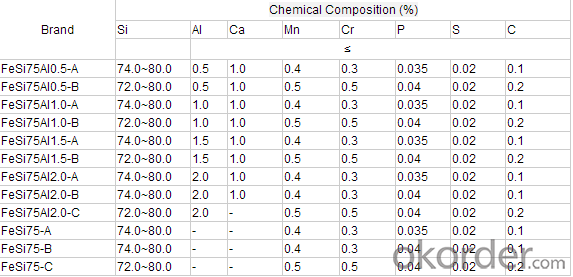

Specification

- Q: Does anyone know what kind of light fireproof materials are there?

- 二, 1, Gypsum plaster board With the building plaster as main raw material, gypsum plaster board is a kind of processed plate made by a special board for protective with an addition of additives and fibers as board core. Gypsum plaster board is characterized by light weight, sound insulation, heat insulation, strong processing performance and simple construction method. 2, Gypsum block Gypsum block is a kind of lightweight building gypsum product which is mainly made of building gypsum, and by adding water, stirring, casting and drying. During the process, , the fiber reinforced materials or light aggregates are allowed in, and the foaming agent can also be added. It has many advantages, such as sound insulation and fire prevention, convenient construction and so on. It is a kind of new and healthy wall material which produces low carbon, enhances environmental protection, and caters to the the times. 3, Fly ash brick is a new type of wall material, and bulk density is one of the main technical indexes. The weight of bulk density can be controlled according to the need of construction and adjustment of technical formula. The dry bulk density of the fly ash brick is about 1540 to 1640 kg / m 3, slightly lighter than the clay brick (1601800 kg /m 3). The flexural and compressive strength of fly ash brick is mainly determined by the production process, the formula and the hydrothermal synthesis reaction mode as well as the need of construction. According to the standards of architectural material industry (JC239 - 2001) released by People's Republic of China, the average value of the flexural strength is 2.5 ~ 6.2Mpa, compressive strength is between 10 ~ 30Mpa. I hope this will be helpful to you

- Q: I wanna ask you, which level is b1 fireproof and thermal inuslation matertial ??

- I soppose you mean rubber and plastic! Only rubber and plastic has b1b2 level. Level b1 is the fireproofing level b1, because the rubber and plastic does not belong to the fireproofing material. It only has fire?retardant. The wholesale of all kinds of thermal insulation material and construction need to look at the name, hope you adopt.

- Q: What kind of refractory materials can withstand 1500℃ when processing briquette stove core and meanwhile cost less?

- Alkali resistant castables cost the least.

- Q: What's the classification of refractory material?

- Magnesium aluminum is complex and mainly seeing what classification standard is like according to the appearance shape can be divided into two categories, setting and not setting according to the acid alkali can be divided into acidic, magnesia, high aluminum, ramming expected, spinel, spray coating, plastic, just the quality of the jade, daub material according to the chemical composition is divided into, such as clay, neutral and alkaline according to the operation mode can be divided into different castable, magnesium, calcium, magnesium chrome

- Q: Which fire-resistant materials have good viscidity?

- Viscidity is necessary for gunning mix, repair mix and bordering. It is too broad to which has good viscidity. Both gunning mix and repair mix are powder before adding water. Bordering also has little viscidity before heating. The question shoule be more specific.

- Q: how is the high-temperature flame-retardant fibre board?

- Temperature refractory fiberboard is of high quality and not likely to be damaged. It is light and easy to install.

- Q: What are the main components of refractory cement?

- SiO powder is often used. Ultra-fine powder refers to less than 1 / zm particles which are made by hydrolysis of ethyl silicate or made from recycled dust in the smelting process of ferro-silicon alloy. Non-cement castable refractory are castable refractory material which contains no cement instead it relies on the coagulation and combination by adding ultra-fine powder or sol (see refractory castable), and it is an amorphous material with high activity. Silica sol is made through Ion-exchange of sodium silicate after Na ions are removed. The easiest method is to prepare by reaction of aluminum metal with hydrochloric acid or alchlor. It is a thermodynamically unstable system which has certain requirements for ultra-fine powder and sol. It is different from non-cement refractory castable, Cr2zrOz and etc. It has low impurity content, and can bond with itself, so it has good binding strength. Ultrafine powder used in non-cement castables are SiO2, Al2O3, Cr2zrOz, etc. Such recycled SiO2 powder has an average particle diameter of 0.5 pm, therefore when adding the gelling agent (electrolyte), it can coagulate and give the products some bonding strength. Non-cement castable refractory is made up of refractory aggregate and powder and it is round. Since the use of superfine powder or sol as binder. The size of sol particles are of 0.1 ~ 1 m. Non-cement refractory castable takes oxide or synthetic compound ultra-fine powder or oxide sol-gel which is similar to the chemical composition of material in tungsten castable. There are several ways to prepare alumina sol. The sol used are mainly alumina oxide and silica sol. The surface area is large, and it helps to improve high-temperature structural strength. Non-cement castable refractories rely on oxide ultra-fine powder or sol to coagulate and combinate. It is a refractory castable (also known as chemical bonding castable) which uses chemical binder instead of cement for combination.

- Q: What is fire retardant coating mainly used for?

- The functions of refractory coating are as follows: 1. Non-intumescent fire retardant coating is mainly used for the fireproofing of wood, fiber board and other materials, and it is used in the surfaces of wood truss, roof, doors, windows and etc. Second, the intumescent fire retardant coating can be divided into non-toxic intumescent fire retardant coating, expansible fire retardant coating emulsions, solvent-based fire retardant coating. 3. Non-toxic intumescent fire retardant coating can be used to protect cables, polyethylene pipes and insulation board. 4, The expansible fire retardant coating emulsion and solvent-based fire retardant coating can be used for fireproofing of buildings, electricity power, and cables. 5. New fire retardant coating: Transparent fire retardant coating, water-soluble intumescent fire retardant coating, fireproof emulsion paint, polyvinyl acetate emulsion fire retardant paint, water-soluble intumescent fire retardant paint drying at room temperature, fire insulation coating polyolefin fire retardant coating, modified high chloropolyethylene fire retardant paint, chlorinated rubber fire retardant coating, firewall coating, intumescent coatings, wire and cable fire retardant paint, new fire retardant coating, casting fire retardant coating and so on.

- Q: Which refractory is better for building 1500 degree kiln ?

- The top and wall use alumina hollow ball brick. If it is cubic kiln, the kiln bottom should use heavy corundum brick. If it is continuous kiln, burning zone should use alumina hollow ball brick, burning zone seal and kiln car face brick. If it is pit furnace, curved seal should use heavy corundum brick, and furnace wall and top should use alumina hollow ball brick. That depends on what kind of kiln it is. Curved seal and kiln car should use heavy corundum brick. You can add me friends to have further talks.

- Q: How to distinguish the fire resistant level of construction materials?

- Division of fire resistant level of building material: 1, It can be divided into five levels according to the importance: a, special class: commerative, historic, international and national buildings. b, Class A: high-grade residential architecture and public building. c, class B: middle-grade residential architecture and public building. d, class C: orinary residential architecture and public building. 2, It can be divided into four grades according to fireproof?performance: Fire resistance level buildings is divided into four levels. Standard of fire resistant level is based on the combustion performance and fire endurance of main components of the house. 3, It can be divided into 4 levels according to durable life: a, A grade durable life, over 100 years, for important buildings and high-rise buildings. b, second level durable life, from 50 to 100 years, for ordinary buildings. c, third level durable life, from 25 to 50 years, for secondary buildings. D, fourth level durable life, less than15 years , for temporary buildings. I hope my answers will help you.

Send your message to us

High-Quality Ferro Silicon Raw Materials for Refractory Applications in South Korea

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords