Factory Of Dioctyl Phthalate DOP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DOP

Molecular Formular : C24H38O4

Molecular weight : 390.57

CAS No.:117-81-7

H.S Code : 2917.3200.00

EINECS No.: 204-211-0

Characteristics : Colorless transparent oily liquid, slight odor.

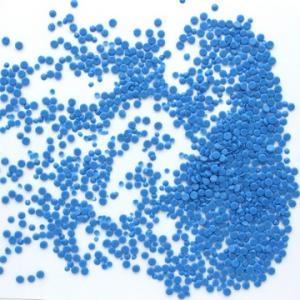

Processing : Injection Moulding

Application : It is one of the most extensively used plasticizers in plastics processing. It has comprehensive properties, such as high plasticizing efficiency, low volatility, UV-resisting property, water-extracting proof, cold-resisting property, and also good softness and electric property. As a fine main plasticizer, it is extensively used in processing polyvinyl choride and ethylcellulose resins to produce plastic film, imitation leather, electric wire, cable wearer, sheet, planet, mould plastic products and. Used in nitrocellulose paints, it can make the ethylcellu lose more elastic and more strong in extracting tension. It can be used as a softening agent of synthetic rubber, such as to make the product easier to rebound and harder to undergo form change under pressure, without affecting of the plastics.

Specifications :

Quality Index | |||

Item | Value | ||

| Super Grade | First Grade | Qualified Grade |

Appearance | Oily liquid | ||

Color(APHA) ≤ | 30 | 40 | 120 |

PurityAs Ester% ≥ | 99.5 | 99.0 | 99.0 |

Acidity (benzene dicarbonic acid)g/cm | 0.01 | 0.015 | 0.03 |

Loss on dry (125oC3hr)%≤ | 0.2 | 0.3 | 0.5 |

Flash point(open)oC ≥ | 195 | 192 | 190 |

Density20,g/cm3 | 0.982-0.988 | ||

Volume Resistivity ΩM ≥ | 1.5×1011 | ||

Heat decrement % ≤ | 0.2 | 0.3 | 0.5 |

Water content,% ≤ | 0.1 | 0.15 | 0.15 |

Package and Storage :

Packed in 200KG/Galvanized Iron Drum or 1000kg/ISO TANK or flexibag container

Stored at dry,shady,ventilated place. Prevented from collision and sunrays,rain-attack during handling and shipping. Met the high hot and clear fire or contact the oxidizing agent,caused the burning

danger.

- Q: What is the raw material used in the production of plastic products?

- The poisonous and harmful substances produced by plastics of this kind of material come from 2 aspects. One is the single molecule vinyl chloride which is not completely polymerized in the process of production, and the other is the harmful substance in the plasticizer (two). These 2 substances in the high temperature and fat when easy to precipitate, toxic substances enter the human body with food, easy to cause cancer. At present, the containers for this material are less used for packaged food. If the family has this kind of material, don't let it heat.

- Q: How many types of plastics are there?

- PVC Name: PVC, mainly used for sealing, inserted conditions. It is adapted to extrusion molding, and PVC material is the material does not burn plastic parts, processing temperature stability, especially the stability of the color is not good.

- Q: How many kinds of plastic do you have?

- Engineering plasticsGeneral engineering plastics include: polyamide, POM, polycarbonate, modified polyphenylene oxide, thermoplastic polyester, ultra high molecular weight polyethylene, methyl amyl polymer, vinyl alcohol copolymer, etc..Special engineering plastics are crosslinked and non crosslinked. The crosslinked types are poly amino bis maleic amide, poly three triazine, crosslinked polyimide, heat-resistant epoxy tree fingers and so on. Non crosslinked types are polysulfone, polyethersulfone, polyphenylene sulfide, polyimide and PEEK.

- Q: Plastic raw materials, why LDPE and LLDPE?

- LDPE is low density polyethylene, that is, high pressure material; LLDPE is linear material.

- Q: PE plastic bellows raw material formula (PE and PP ratio, as well as other filling)?

- PP and PE plastic corrugated pipe in the role of the following two: 1, PP material can reduce the production of pipe, HDPE than PP pipe grade market sales price higher, the production of HDPE pipeline adding appropriate amount of PP, for the reduction of raw materials

- Q: How do you increase the transparency and hardness of PP plastic suction pipes? What raw materials do you need to add?

- Add transparent nucleating agents to improve transparency, such as milk tea cups

- Q: What are the main biodegradable plastic bags made of?

- At present, developed a new biodegradable plastic, its composition is polyvinyl alcohol starch plus photosensitizer synthesis, polyvinyl alcohol was easy to degrade than polyethylene, adding photosensitizer can absorb sunlight to accelerate the degradation by plastic, starch can promote the degradation of plastic in soil speed. As a result, this new biodegradable plastic is easier to degrade than the former, and it decomposes into a substance of simple molecular structure, such as carbon and water, which is more environmentally friendly.

- Q: What are the raw materials needed for producing plastic hair dryer shell and flashlight shell?

- Water absorbency. Nylon has high water absorption, and saturated water can reach more than 3%. To a certain extent, the dimensional stability of the parts is affected

- Q: What are the raw materials needed for making plastic bags?

- The bags made of two materials each have their own characteristics, and are chosen according to the purpose and performance of the products. Polyethylene is petrochemical products, prices vary according to crude oil and market conditions every day, at present LDPE (high pressure polyethylene) offer at 13500 yuan. HDPE (low pressure polyethylene) at 11000 yuan up and down.

- Q: Is plastic raw material rubber?

- The difference between the plastic and the rubber is plastic or not, but because of thermosetting plastics, this definition is not comprehensive. Another difference is whether the elastic body, but because of the appearance of thermoplastic elastomer, this definition is not comprehensive. In general, rigid high molecular material thermoplastic processing, sure is a plastic elastomer; and thermosetting rubber must be classified. The more ambiguous reference history. Silicone rubber and polyurethane is thermosetting elastomer rubber, is, but completely different from natural rubber. There is a part of polyurethane is thermosetting plastics, even thermoplastics, composition, structure and it depends on the characters.

Send your message to us

Factory Of Dioctyl Phthalate DOP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords