F Series Triplex Mud Pump Package for Drilling Rig

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of F Series Triplex Mud Pump Description

1) Power End:

The frame is of welded-steel pale construction, with characteristics of high strength , good rigidity and light weight due to internal stress eliminating treatment after being welded .

Integral herringbone gear drive is adopted for smooth running, high efficiency and long operating life. The crank shaft is alloy steel castings.

Double-deck sealing is adopted in intermediate pull rod with sound sealing effect.

The power end adopts the lubricating method of forced lubrication combined with splash lubrication.

2) Fluid end:

The hydraulic cylinder material is alloy steel forging. Straightway hydraulic cylinder has good suction performance.

Suction valve and discharge valve on F series pump are interchangeable.

Pump F-500 uses API 5# valve; pump F-800 and F-1000 use API 6# valve ; pump F-1600 uses API 7# valve.

2. Main Features of F Series Triplex Mud Pump

1) Advanced test for quality

2) MTC provided

3) Good price and service

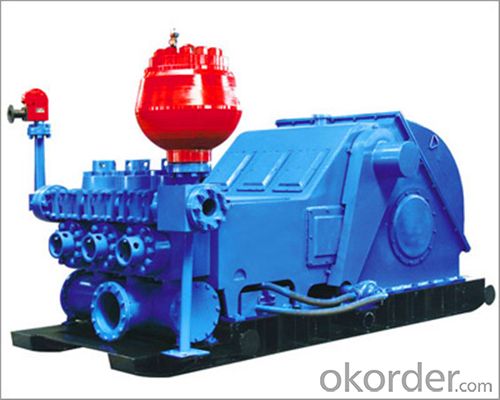

3. F Series Triplex Mud Pump Images

4. F Series Triplex Mud Pump Specification

Model | F-500 | F-800 | F-1000 | F-1300 | F-1600 |

Power kw(ps) | 373(500) | 597(800) | 746(1000) | 969(1300) | 1193(1600) |

Strokes per minutes pm | 165 | 150 | 140 | 120 | 120 |

Stroke mm | 190.5(7.5″) | 229 (9″) | 254 (10″) | 305 (12″) | 305 (12″) |

Gear ratio | 4.286:1 | 4.185:1 | 4.207:1 | 4.206:1 | 4.206:1 |

Max.working pressure Mpa | 34.5 | 34.5 | 34.5 | 34.5 | 34.5 |

Max.Dia.of liner mm | 170 | 170 | 170 | 180 | 180 |

Dia. Of suction pipe mm | 203 | 254 | 305 | 305 | 305 |

Dia. Of discharge pipe in | 4 | 5-1/8 | 5-1/8 | 5 | 5 |

Weight kg | 9543 | 14000 | 18642 | 24572 | 24791 |

5. FAQ of F Series Triplex Mud Pump

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

One of the leading manufacturers and suppliers specializing in this product in China, supply a wide variety of accessories consists of our one-stop sales. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: 5 floor water pressure is too low, what kind of water pump is better?

- The location of the pump is too far away from the pumping pool, the suction of the pump is not enough, cavitation phenomenon, pumping water, this water pump manufacturers, the pump will be placed in a reasonable position

- Q: If you use an ordinary 15W submersible pump, put it in the tank, if the leakage, the fish will hang it?

- Submersible pump even if it really leakage, it will not cause the fish electric shock. The so-called leakage is the submersible pump wire or shell broken, live parts and water contact, the most extreme test is a fire line directly into the fish tank

- Q: The difference between submersible pumps and centrifugal pumpsWhat's the difference between the two? What is applicable and what?

- Difference:The installation position is different: one can discharge water, one is on the ground.The work principle is different: the principle of submersible pump is similar to the electric fan, centrifugal pump through centrifugal force to make the water throw out. According to the principle of centrifugal force design,

- Q: The distance from the pump button to the ground

- Yellow warning pop-up, indicating that the fire control room has issued alarm information, fire alarm controller (commonly known as the alarm host)

- Q: How to install, operate and maintain the pipeline booster pump?

- The motor coil is provided with a safety protector, and when the pump is out of order or the water is not pumped, the motor can automatically break down when the temperature of the motor exceeds the prescribed value, and the motor can automatically resume operation after the temperature rise of the motor is decreased. The booster pump motor is a capacitor running type motor. When the pump leaves the factory, the rotation direction has been adjusted. If you need to replace the capacitor or re connect, press the arrow direction on the pump body to mark the connection. To ensure safety, use the three - core safety socket with ground wire.

- Q: How is the pump level of submersible sewage pump determined?

- Generally as:The bottom elevation of sump sump plus 300 is the water level of pump stopThe top 300 of the sump top elevation is the pump water level

- Q: Rules for operation of centrifugal pumps

- 3, start the pump, wait until the speed reaches the normal speed, slowly open the outlet valve, observe the ammeter at the same time, and control the current in the rated current range of the motor.4, the operation requires smooth operation of water pumps, no abnormal noise, no pressure fluctuations. The abnormal situation should be stopped in time.

- Q: How can I buy a pump?

- 3 、 mechanical requirements of high reliability, low noise, vibration.4, the correct calculation of pump procurement costs, the pump manufacturer to inspect, requiring good quality equipment, good after-sales service, spare parts can be timely supply.The micro pump and the motive of the mechanical energy or other external energy transmitted to the liquid, the liquid energy increase, mainly used to transport liquids including water, oil, alkali liquid, emulsion, suspension emulsion and liquid metal, but also transport liquid, gas mixtures and liquids containing suspended solids.The technical parameters of pump performance include flow, suction, lift, shaft power, water power, efficiency and so on.

- Q: What's the word "pump"? Is that what advocates mean?RT

- What is a "fan"?In recent years, the term "fan" often appears on the newspaper Web page, whether it is a team, a singer, a sports car and a toilet, all of which have their own fans

- Q: Which nuclear submarines use the shaftless pump technology?

- Shaftless pumping technology and Simulation of shark skin technology are all the next generation of submarine propulsion technology. At present, there is no submarine in the world.

Send your message to us

F Series Triplex Mud Pump Package for Drilling Rig

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords