Extra Long Aluminum Sheets - Aluminium Slab with Best Discount Price in Low Price Cheaper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 400 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

Cold rolled and hot rolled and cold drawn and hot drawn aluminum sheet and plate and slab are all widely used in the field of construction field and decoration field, etc. There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,6063,8011, etc.

The temper is include H14, F, H22, H24, H44,O,H112,H114,etc.

2. Main features of the product

a. The best cheaper price with Competitive price

b.Frist-Class Service.

c. Shortest service.

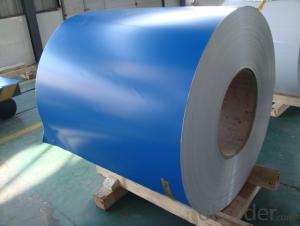

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438, 500*600,700*800,900*900,1220mm*2440mm,

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 100mm to 2500mm, etc.

---Normally it is from Japan, USA, Enaland ,SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Can aluminum sheets be used for decorative wall panels?

- Yes, aluminum sheets can be used for decorative wall panels. Aluminum is a versatile material that offers a wide range of design options for wall panels. It is lightweight, durable, and resistant to corrosion, making it suitable for both interior and exterior applications. Aluminum sheets can be easily cut, formed, and fabricated into various shapes, patterns, and finishes, allowing for endless design possibilities. Additionally, aluminum can be powder-coated or anodized to enhance its appearance and provide additional protection against wear and tear. Whether it's for residential or commercial spaces, aluminum sheets can add a modern and stylish touch to any wall, making them a popular choice for decorative wall panels.

- Q: Does aluminum foil keep food warm or cool, or is it just a convenient material to cover food with?

- Yes, but not very long. Styrafoam is always the best for insulation.

- Q: What characteristics distinguish aluminum sheets from other types of sheets?

- <p>Aluminum sheets are lightweight, corrosion-resistant, and have excellent thermal and electrical conductivity. They are commonly used in construction, automotive, and packaging industries. In contrast, other types of sheets, such as steel sheets, are heavier and stronger but less resistant to corrosion. Plastic sheets are lightweight and flexible but have lower strength and thermal conductivity. Copper sheets offer high thermal and electrical conductivity but are more expensive and less resistant to corrosion than aluminum. Each type of sheet has unique properties that make it suitable for specific applications.</p>

- Q: Are 101 aluminum sheets suitable for architectural louvers or sunscreens?

- Yes, 101 aluminum sheets are suitable for architectural louvers or sunscreens. 101 aluminum is a commercially pure aluminum alloy that offers good corrosion resistance and excellent formability. It is commonly used in architectural applications due to its lightweight nature, ease of fabrication, and ability to withstand various weather conditions. In the case of louvers or sunscreens, 101 aluminum sheets can be easily shaped and cut into the desired form, allowing for the creation of functional and aesthetically pleasing architectural elements. Additionally, the corrosion resistance of 101 aluminum ensures that the louvers or sunscreens will remain structurally sound and visually appealing over time.

- Q: This question asks for a list of various methods used to treat the surface of aluminum sheets to improve their properties or appearance.

- <p>There are several types of surface treatment for aluminum sheets, each serving different purposes. These include: Anodizing, which creates a protective oxide layer and enhances corrosion resistance; Chemical Conversion Coating, such as chromate conversion, to improve paint adhesion and corrosion resistance; Electrolytic Polishing, which provides a smooth, shiny surface; Powder Coating, an electrostatic process that applies a durable coating; Paint Coating, offering a wide range of colors and finishes; and Mechanical Polishing, which smooths the surface and improves reflectivity. Each treatment has its specific applications and benefits, depending on the desired outcome for the aluminum sheet.</p>

- Q: What is the maximum temperature aluminum sheets can withstand?

- The maximum temperature that aluminum sheets can withstand varies depending on the specific grade of aluminum. However, most aluminum alloys have a melting point ranging from 600 to 660 degrees Celsius (1112 to 1220 degrees Fahrenheit).

- Q: What is the standard thickness of aluminum sheets used for exterior building applications?

- <p>The typical thickness of aluminum sheets used for building exteriors ranges from 0.7mm to 1.2mm. This range is suitable for applications such as facades, cladding, and roofing. The specific thickness can vary depending on the structural requirements, wind loads, and the overall design of the building. Thicker sheets may be used for more robust structures or in areas with higher wind pressures, while thinner sheets can be used for lighter applications or when a more aesthetically pleasing finish is desired.</p>

- Q: Can aluminum sheets be used for aircraft manufacturing?

- Yes, aluminum sheets are commonly used in aircraft manufacturing due to their lightweight yet strong properties, making them ideal for constructing various components such as wings, fuselage, and structural parts. Aluminum's excellent corrosion resistance and high strength-to-weight ratio make it a preferred choice in the aerospace industry.

- Q: Can aluminum sheets be used for architectural applications?

- Architectural applications can definitely make use of aluminum sheets. Aluminum, being a lightweight and versatile material, offers numerous advantages for architectural projects. It possesses durability, resistance to corrosion, and the ability to withstand extreme weather conditions, making it an ideal choice for different architectural applications like roofing, cladding, facades, windows, doors, and decorative elements. The availability of aluminum sheets in various thicknesses, finishes, and colors allows architects and designers to achieve their desired aesthetic while maintaining structural integrity. With the material's flexibility in being easily shaped, bent, and formed into complex designs, architects are provided with creative freedom and flexibility. Aside from its aesthetic appeal, aluminum is also an environmentally sustainable choice for architectural applications. It is highly recyclable, contributing to a high recycling rate and promoting eco-friendly options. The use of aluminum sheets in architectural projects helps in reducing the carbon footprint and promoting sustainable design practices. Moreover, aluminum sheets offer excellent thermal and acoustic properties that contribute to energy efficiency and sound insulation in buildings. The material aids in reducing energy consumption and enhancing occupant comfort, making it an attractive option for architects and building owners. In conclusion, the versatility, durability, sustainability, and aesthetic appeal of aluminum sheets make them a popular choice for architectural applications. They provide numerous benefits and can be utilized in various ways to create stunning architectural designs while ensuring long-lasting performance.

- Q: What is the weight of aluminum sheets?

- The weight of aluminum sheets can vary depending on the thickness and dimensions of the sheet. As a general guideline, the weight of aluminum sheets can range from about 2.7 grams per square centimeter (g/cm^2) for thin sheets to around 6.9 g/cm^2 for thicker sheets. However, it is important to note that these values are approximate and can vary slightly depending on the specific alloy and manufacturing process used. Therefore, it is recommended to consult the manufacturer or supplier for precise weight specifications for a particular aluminum sheet.

Send your message to us

Extra Long Aluminum Sheets - Aluminium Slab with Best Discount Price in Low Price Cheaper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 400 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords