Home Depot Decorative Aluminum Sheets - Aluminium Slab with Best Discount Price in Cheaper Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

Cold rolled aluminum sheet is of construction field and decoration field, etc. There are many different grades, such as: 1000 series, 6000 series, 8000 series, 3000 series, etc.

2000 series, 3000 series, 5052,6063,8011, etc.

The temper is include H14, H22, H24, O, F, H44,H112,O, F,H114,etc.

2. Main features of the product

a. the best cheaper Competitive price

b.Frist-Class Service.

c. Shortest service.

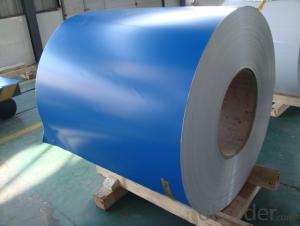

3. Image.

4. Product detailed sizes:

1000mm*2000mm,500*500, 600*600,1219mm*2438mm,1220mm*2440mm,

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 400mm to 2500mm, etc.

---Normally it is from Japan, USA, fiji , sri lnala, bangladesh, etc.

ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are checkered sheet and mirror sheet, and else grades for different sizes of aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: I have no idea, and I can't figure this out, and neither can my aunt and she's super smart. It's this project that's due on Monday, and if I can't get it turned in, then I get detention and a failing lab grade. The only information I have is it's $2.96 for a roll of aluminum, it contains 2.96 square meters, and it weighs .995 grams...

- 3 square meters masses less than a gram - surely not But lets assume you have 0.995 grams. Dividing this number by 26.98(molar mass of AL) would give you moles of Al. Multiplying the number of moles X Avogadro's number (6.022 X 10^23) would give you atoms of Al. That number of atoms will cost you $2.96 . Dividing the cost by the total number of atoms will give you dollars per atom.

- Q: Can aluminum sheet be used for automotive heat shields?

- Yes, aluminum sheet can be used for automotive heat shields. Aluminum is a popular choice for heat shields in the automotive industry due to its excellent thermal conductivity and high heat resistance. It helps to protect sensitive components from excessive heat by reflecting and dissipating the heat away from the desired areas. Additionally, aluminum is lightweight and corrosion-resistant, making it an ideal material for automotive applications. It is commonly used in various heat shield designs, including exhaust heat shields, engine heat shields, and under-carriage heat shields.

- Q: What are the typical thickness options for aluminum sheets?

- The typical thickness options for aluminum sheets vary depending on the specific application and industry requirements. However, aluminum sheets are commonly available in a range of thicknesses. Some of the most common thickness options for aluminum sheets include 0.025 inches (0.635 mm), 0.032 inches (0.81 mm), 0.040 inches (1.02 mm), 0.050 inches (1.27 mm), 0.063 inches (1.6 mm), 0.080 inches (2.03 mm), and 0.125 inches (3.18 mm). These thicknesses are often used in various industries such as aerospace, automotive, construction, and manufacturing. It's worth noting that specialty aluminum sheets can be found in even thicker options, depending on the specific requirements of a particular project.

- Q: Can aluminum sheet be used for insulation?

- Although aluminum sheet can be utilized for insulation purposes, it is not as efficient as alternative insulation materials like fiberglass or foam. This is due to its low thermal conductivity, which implies that it is not a proficient heat conductor. Nevertheless, aluminum lacks adequate insulating properties on its own since it does not offer substantial resistance to heat flow. To enhance its effectiveness for insulation, aluminum sheet is frequently combined with other insulating materials. For instance, aluminum foil is commonly employed as a radiant barrier in buildings to reflect heat and diminish the amount of heat transferred through walls and roofs. In summary, while aluminum sheet can contribute to insulation, it is typically employed in conjunction with other materials to provide superior thermal insulation.

- Q: Are 101 aluminum sheets resistant to corrosion?

- Yes, 101 aluminum sheets are resistant to corrosion due to the presence of a protective oxide layer on their surface, which helps prevent the metal from reacting with its environment.

- Q: On the web page to see more information on the plating aluminum plate, I do not know what is the difference between aluminized and aluminum plating performance?

- Brief introduction of hot dip aluminizing of steelHot dip aluminizing of steel is a new type of coating process for forming alloy aluminum layer on the surface of steel when molten steel products are inserted into molten aluminum liquid at a certain temperature.Hot dipped aluminized steel has high strength of steel matrix and corrosion resistance, wear resistance and high temperature resistance of aluminum layer. Its corrosion resistance is 5-10 times that of galvanized steel; it is resistant to sulfide and heat corrosion. Its performance is better than 18-8 stainless steel. Therefore, it can bring obvious economic benefits to users.

- Q: This question asks for a comparison between aluminum sheets and other lightweight materials like plastic and glass, focusing on their properties and uses.

- <p>Aluminum sheets are lightweight yet strong, offering excellent strength-to-weight ratios. They are more durable and heat resistant compared to plastics, which can deform under heat and are less sturdy. Unlike glass, aluminum is less brittle and does not shatter, making it safer for certain applications. Additionally, aluminum is recyclable and has good thermal and electrical conductivity, which is not the case with plastics. However, plastics are generally cheaper and easier to shape into complex forms, while glass offers better transparency for applications requiring clear visibility. Each material has its advantages depending on the specific requirements of the application.</p>

- Q: Can aluminum sheets be anodized?

- Yes, aluminum sheets can be anodized. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum. This layer enhances the metal's corrosion resistance, durability, and appearance. Anodizing is commonly used in various industries such as automotive, aerospace, and construction to provide a protective coating and improve the aesthetics of aluminum sheets. The process involves immersing the aluminum sheet in an acid electrolyte solution and passing an electric current through it, causing oxygen ions to bond with the aluminum atoms and form the oxide layer. This layer can be further enhanced with the addition of dyes or pigments to create different colors and finishes. Overall, anodizing is a versatile and effective method for treating aluminum sheets.

- Q: Are aluminum sheets suitable for lighting fixtures?

- Yes, aluminum sheets are suitable for lighting fixtures. Aluminum is a lightweight and durable material that can be easily shaped and manipulated to create various designs for lighting fixtures. It also has excellent heat dissipation properties, which is crucial for ensuring the longevity and performance of lighting fixtures. Additionally, aluminum is corrosion-resistant, making it suitable for both indoor and outdoor lighting applications.

- Q: what kind of aluminum sheet is suitable for aluminum alloy double-edged saw?

- general horizontal driving sawing and precision sawing.

Send your message to us

Home Depot Decorative Aluminum Sheets - Aluminium Slab with Best Discount Price in Cheaper Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords