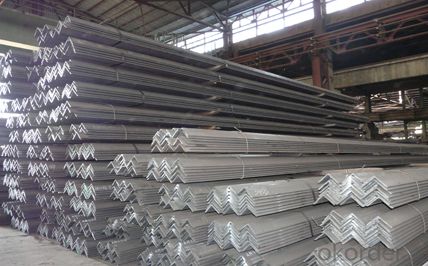

Equal Angle Steel Hot Rolled / Steel Angle Bar /Q235B Angle Size

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | As standard export package |

| Delivery Detail: | 15days to 20days |

hot rolled equal angle steel/ steel anglesbar /Q235B angle size

Model | Specification | Weight kg/M |

2.5# | 25*3 | 1.124 |

25*4 | 1.459 | |

3# | 30*3 | 1.373 |

30*4 | 1.786 | |

4# | 40*3 | 1.852 |

40*4 | 2.422 | |

40*5 | 2.976 | |

5# | 50*4 | 3.059 |

50*5 | 3.77 | |

50*6 | 4.465 | |

6# | 60*5 | 4.57 |

60*6 | 5.42 | |

6.3# | 63*5 | 4.822 |

63*6 | 5.721 | |

63*8 | 7.469 | |

7# | 70*5 | 5.397 |

70*6 | 6.406 | |

70*7 | 7.398 | |

70*8 | 8.373 | |

7.5# | 75*5 | 5.818 |

75*6 | 6.905 | |

75*7 | 7.976 | |

75*8 | 9.03 | |

75*10 | 11.089 | |

8# | 80*6 | 7.376 |

80*8 | 9.658 | |

80*10 | 11.874 | |

9# | 90*8 | 10.946 |

90*10 | 13.476 | |

90*12 | 15.94 | |

10# | 100*6 | 9.366 |

100*8 | 12.276 | |

100*10 | 15.12 | |

100*12 | 17.898 | |

11# | 110*8 | 13.532 |

110*10 | 16.69 | |

110*12 | 19.782 | |

110*14 | 22.809 | |

12.5# | 125*8 | 15.504 |

125*10 | 19.133 | |

125*12 | 22.696 | |

125*14 | 26.193 | |

14# | 140*10 | 21.488 |

140*12 | 25.522 | |

140*14 | 29.49 |

Equal angle steel Manufacturer from ShangHai China

1.Material: Q235B, SS400, A36, ST37-2, S235JR,Q345,S355JR,SJR275,SM490,ST-52

2.Surface: Oil, Black, Galvanized, Painted

3. Length: 6-12m or according to our clients' requirements

4. Main market: East-south Asia, Mid-east, South America, South Africa

5. Package:load on 20 feet/40 feet container or by bulk according to the quantity and our client's requirement

6. Payment: 100% irrevocable L/C at sight or T/T

7. Delivery time: within 10-15 days after confirming order and deposit received.

8. Applicant: Widely used in all kinds of architecture and engineering structure, such as the beam, Bridges, transmission tower, lifting transportation machinery, the ships, the industrial furnace,container frame and warehouse shelves, etc..

9. Related products available: Steel plates, steel coils, steel angle, H-beam steel, steel channels, I-beams steel , welded pipe, Galvanized pipe, steel rail, steel bar--round , flat ,Checkered and square.

- Q: Can steel angles be painted over?

- Yes, steel angles can be painted over. Prior to painting, it is important to ensure that the surface is clean and free from any dirt, oil, or rust. This can be achieved by using a wire brush or sandpaper to remove any loose particles and then wiping the surface with a clean cloth. Once the surface is properly prepared, a primer specifically designed for metal surfaces should be applied to promote adhesion and prevent corrosion. After the primer has dried, a suitable paint can be applied using a brush, roller, or spray gun. It is recommended to use paints that are specifically formulated for metal applications to ensure proper adhesion and durability. Regular maintenance and repainting may be required over time to maintain the appearance and protect the steel angles from corrosion.

- Q: Can steel angles be used in staircases?

- Yes, steel angles can be used in staircases. Steel angles are commonly used as structural elements in construction due to their strength and versatility. In staircases, steel angles can be used to provide support and stability to the steps and handrails. They are often used as stringers, which are the inclined structural members that support the treads and risers of the staircase. Steel angles can also be used to reinforce the connections between the treads and risers, ensuring the structural integrity of the staircase. Additionally, steel angles can be used as handrails or balusters, providing a secure and durable railing system. Overall, steel angles offer a reliable and cost-effective solution for constructing staircases that can withstand heavy loads and meet the necessary safety standards.

- Q: What are the different types of steel angles available?

- There exists a variety of steel angles available, each specifically designed for particular applications and purposes. Examples of these include: 1. Equal Angle: These steel angles, also referred to as L-shaped angles, possess equal side lengths and are commonly utilized for general structural and construction purposes. They offer exceptional support and stability when interconnected with other structural components. 2. Unequal Angle: As the name implies, unequal angles feature different side lengths. These angles are frequently employed in applications where one side needs to be longer or shorter than the other, such as supporting uneven loads or creating specific shapes. 3. Stainless Steel Angle: Constructed from stainless steel, these angles exhibit high resistance to corrosion, making them suitable for applications where exposure to moisture or chemicals is a concern. They find common usage in food processing plants, chemical industries, and marine environments. 4. Galvanized Angle: Galvanized steel angles are coated with a layer of zinc, thereby providing excellent corrosion resistance. This makes them ideal for outdoor applications or areas exposed to high humidity or saltwater. 5. Rolled Steel Angle: Rolled steel angles are produced by rolling hot-rolled steel into the desired shape. This process enhances the angle's strength and durability, rendering it suitable for heavy-duty applications. 6. Slotted Angle: Slotted angles feature holes or slots along their length, facilitating easy attachment and adjustment. They are commonly utilized in shelving systems, workbenches, and storage racks, as they offer a versatile and customizable solution. 7. Structural Steel Angle: These angles are mainly deployed in construction projects requiring load-bearing support. They are designed to withstand heavy loads and provide structural stability in buildings, bridges, and other infrastructure projects. It is crucial to assess the specific requirements of your project before selecting the appropriate type of steel angle. Seeking guidance from a structural engineer or steel supplier can ensure that you choose the correct angle for your application.

- Q: What are the different types of connections used for steel angles?

- Steel angles can be connected in several ways, depending on the application and load requirements. Here are some commonly used connections: 1. Welded Connection: The most frequently used connection for steel angles involves welding them to other members, such as beams or columns. These connections offer high strength and stiffness, making them suitable for heavy loads and structural purposes. 2. Bolted Connection: Another option is to bolt the steel angles to the connected members using bolts and nuts. Bolted connections are preferred when the structure may need to be disassembled or relocated. They offer flexibility, adjustability, and easy installation. 3. Riveted Connection: While not as commonly used nowadays, riveted connections were widely employed in older structures. Riveting involves joining the steel angle to other members using rivets. Although they require skilled labor for installation, riveted connections provide good strength and durability. 4. Clip Connection: A clip connection is a type of bolted connection where a clip or bracket is used to secure the steel angle to the supporting member. This allows for easy assembly and disassembly, making it suitable for temporary structures or situations requiring frequent modifications. 5. Shear Connection: Shear connections use shear plates or angles to connect the steel angle to the supporting member. These connections primarily transfer shear forces and provide sufficient strength and rigidity. 6. Cleat Connection: Cleat connections involve using a cleat plate, typically welded or bolted, to connect the steel angle to the supporting member. Cleat connections are commonly employed in industrial applications where heavy loads and high forces need to be transferred. When selecting the appropriate type of connection for steel angles, it is crucial to consider the specific requirements of the structure, including load capacity, design codes, and environmental conditions. Consulting with a structural engineer or referring to relevant design standards can ensure the proper selection and installation of the connection.

- Q: What are the common design codes and standards for steel angles?

- The common design codes and standards for steel angles depend on the specific application and industry requirements. However, some widely recognized design codes and standards applicable to steel angles include: 1. American Institute of Steel Construction (AISC): AISC provides design specifications and standards for structural steel construction, including angles. The AISC Steel Construction Manual offers guidance on the design of steel structures, including the selection and design of steel angles. 2. American Society for Testing and Materials (ASTM): ASTM International develops and publishes technical standards for various materials, including steel. ASTM A36/A36M is a commonly referenced standard for carbon structural steel, including angles. It specifies the requirements for chemical composition, mechanical properties, and testing methods. 3. European Norm (EN): The European Norm specifies technical delivery conditions for structural steel products. EN 10025-2 covers non-alloy structural steels, including angles, and provides requirements for chemical composition, mechanical properties, and tolerances. 4. British Standards Institution (BSI): The BSI publishes a range of standards relating to steel angles, including BS EN 10056-1, which details the dimensions and tolerances for hot-rolled equal and unequal steel angles. 5. Canadian Standards Association (CSA): CSA standards provide guidance for steel design and construction in Canada. CSA G40.21 is a widely used standard that covers the requirements for general structural steel, including angles. It is important to note that these are just some examples of the common design codes and standards for steel angles. Depending on the specific project and geographic location, there may be additional local or industry-specific codes and standards that need to be considered when designing and specifying steel angles. Consulting with a structural engineer or referring to the relevant design codes and standards is crucial to ensure compliance and safety in the design and construction of steel angles.

- Q: Can steel angles be used as supports for solar panels?

- Yes, steel angles can be used as supports for solar panels. Steel angles are commonly used in construction due to their strength and durability. When properly designed and installed, steel angles can provide a sturdy and reliable support structure for solar panels. They can be easily welded or bolted together to create a secure framework that can withstand the weight of the panels and any environmental factors such as wind loads. Additionally, steel angles can be galvanized or coated to enhance their resistance to corrosion, making them suitable for outdoor applications such as solar panel installations.

- Q: Can steel angles be used in high-temperature applications?

- Depending on the alloy and temperature range, steel angles can be utilized in high-temperature scenarios. Stainless steels and heat-resistant alloys, which are specifically engineered for high-temperature applications, possess the ability to endure elevated temperatures without compromising strength or structural integrity. These alloys typically contain elements such as chromium, nickel, or molybdenum, which enhance resistance against corrosion, oxidation, and high temperatures. Nonetheless, it is imperative to acknowledge that not all steel angles are appropriate for high-temperature uses. Ordinary carbon steels, for instance, have a restricted temperature range before experiencing strength loss and becoming vulnerable to deformation or failure. The precise temperature threshold for a specific steel angle relies on factors such as alloy composition, heat treatment, and duration of exposure to high temperatures. To recap, steel angles can be employed in high-temperature applications if they are constructed from suitable alloys specifically designed for such conditions. It is essential to consult materials engineers or experts who can provide guidance on appropriate steel alloys and temperature limits for a given application to ensure performance that is safe and reliable.

- Q: How do steel angles provide structural support?

- Structural support is provided by steel angles, which evenly and efficiently distribute weight and load in a structure. These L-shaped steel beams are commonly used in construction. The stability and strength of the angle's two legs enable it to resist bending and twisting forces. Steel angles are frequently combined with other structural components like beams, columns, and trusses to establish a stable framework. They can be connected to these components through bolting, welding, or other methods to offer additional support and reinforcement. Due to their versatility, steel angles can be utilized in various applications, including building frames, supports, bracing, and structural reinforcement. The incorporation of steel angles in a structure helps evenly distribute weight and load across different components, reducing the risk of structural failure. They effectively resist compressive, tensile, and bending forces, providing stability and preventing deformation under heavy loads or external forces like wind or earthquakes. Furthermore, steel angles serve to create secure connections and joints between different parts of a structure, ensuring their firm fastening. This enhances overall stability and integrity, making the structure more resistant to movement, vibrations, and other external factors that could compromise safety. In summary, steel angles play a vital role in providing structural support. They distribute weight, resist bending and twisting forces, enhance stability, and reinforce connections between different structural components. Their strength, versatility, and reliability make them a popular choice in construction projects where structural integrity and stability are paramount.

- Q: Are steel angles resistant to high winds?

- Steel angles are able to resist high winds. Steel is renowned for its strength and durability, making it an excellent choice for structures requiring the ability to withstand strong winds. Specifically, steel angles offer added stability and support to buildings by distributing the load and resisting bending forces. Consequently, they exhibit a high level of resistance against the powerful forces exerted by high winds. Moreover, steel angles are commonly utilized in the construction of buildings and infrastructure in areas that are susceptible to hurricanes, tornadoes, or other severe weather conditions, further demonstrating their capacity to withstand high winds. In summary, steel angles are a dependable and efficient solution for ensuring structural integrity and wind resistance in diverse applications.

- Q: Are steel angles suitable for earthquake-prone areas?

- Yes, steel angles are suitable for earthquake-prone areas. Steel is a strong and durable material that can withstand seismic forces and provide structural stability during earthquakes. The use of steel angles helps distribute the load and reinforce the structure, making it more resistant to seismic activity.

Send your message to us

Equal Angle Steel Hot Rolled / Steel Angle Bar /Q235B Angle Size

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords