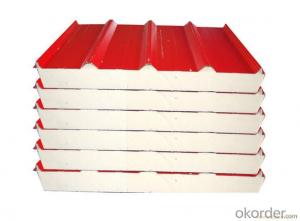

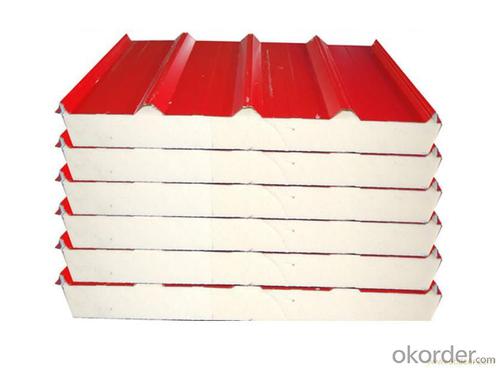

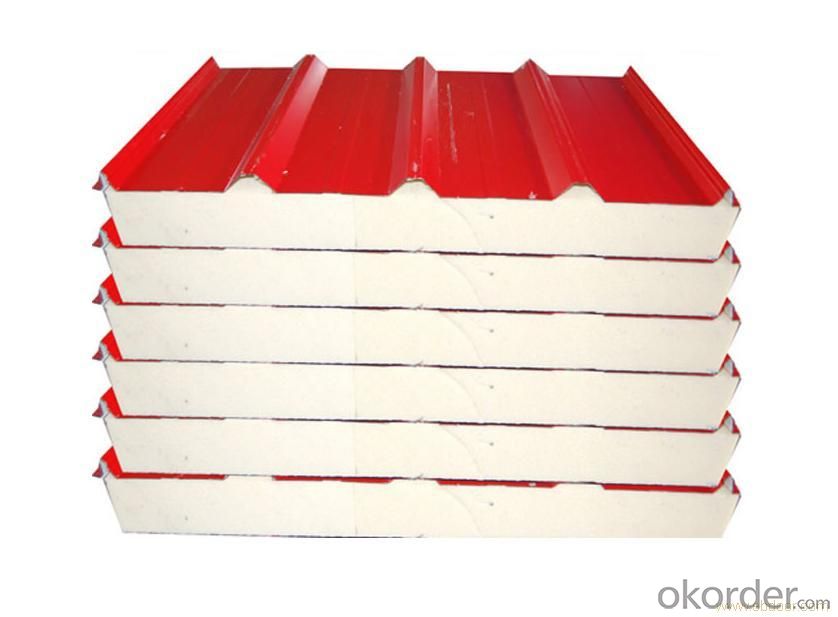

EPS Roof Sandwich Panel/Polystyrene Foam Sandwich Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 25000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Sandwich panels are used in those applications where high structural rigidity and low weight is required. An evident example of use of sandwich panels is aircraft where mechanical performance and weight saving is essential. Other applications include packaging (e.g. fluted polypropylene boards of polypropylene honeycomb boards), transportation and automotive as well as building & construction.

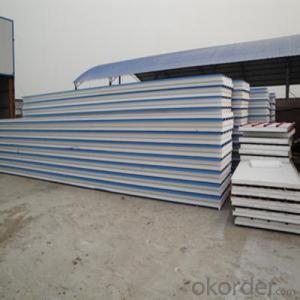

Packaging & Delivery

Packaging Details:covered by LDPE Guard Film and put into the container directly or as required

Delivery Detail:25 working days after receiving 30% deposit

Specifications

1) Sandwich Roof Panel

2) Light Weight,Sound Insulation

3) Heat Insulation,Preservation

4)Fire,Water Proof

5) Fast, Easy

Size

UP/LOWER STEEL SHEET:

Thickness: 0.2mm-0.8mm

Width: 960mm

Material: color-coated panel/zinc plate,hot galvanized plate

Surface: LDPE Guard Film

EPS BEADS:

Density:80kg--120kg/m3

Thickness: 40mm-50mm-75mm-100mm-120mm-150mm-170mm

Length: considering the transportation, it is better don't beyond 11.8 meters.

Rockwool Sandwich Panel Introduce:

Thickness:50mm-150mm

Width:950mm-1150mm

Steel Thickness:0.2mm-0.80mm

rockwool sandwich panel:

Features of rockwool sandwich panel as follows:

- Q: Are steel sheets suitable for high-temperature applications?

- Yes, steel sheets are suitable for high-temperature applications due to their high melting point, excellent strength, and heat resistance properties. Steel sheets can withstand extreme temperatures without losing their structural integrity, making them ideal for applications such as furnace linings, heat exchangers, and exhaust systems.

- Q: Are the steel sheets resistant to UV radiation?

- Generally, steel sheets are resistant to UV radiation. Steel, being a highly durable material, can endure exposure to different environmental factors, including UV radiation. However, the level of resistance may differ depending on the specific type of steel and its protective coating. Steel sheets with a superior protective coating, such as galvanized or stainless steel, exhibit greater resistance to UV radiation compared to bare steel. These coatings act as a barrier, preventing direct impact of UV rays on the steel surface and reducing the chances of degradation or discoloration. Moreover, regular maintenance and proper care can further bolster the steel sheets' resistance to UV radiation, ensuring their long-term durability and performance.

- Q: How are steel sheets joined together?

- Steel sheets can be joined together through various methods such as welding, riveting, bolting, or using adhesives.

- Q: Can steel sheets be used in high-temperature applications?

- High-temperature applications can make use of steel sheets, as steel possesses exceptional heat resistance and can endure high temperatures while retaining its structural integrity. The suitability of steel for such applications is heavily influenced by its specific type and composition. Stainless steel or heat-resistant steel, for instance, are specifically engineered to withstand exceedingly high temperatures and are widely utilized in industries like aerospace, automotive, and manufacturing. These steel sheets are applicable in various high-temperature settings including furnaces, boilers, exhaust systems, and heat exchangers, among others. Nevertheless, it is crucial to consider factors such as the precise temperature range, duration of exposure, and the presence of any potentially corrosive elements in the high-temperature environment to ensure the selected steel sheet is suitable for the intended purpose.

- Q: How thick are steel sheets typically?

- Steel sheets can vary in thickness depending on their intended use, but they typically range from 0.5 to 6 millimeters thick.

- Q: Can steel sheets withstand extreme weather conditions?

- Yes, steel sheets are designed to withstand extreme weather conditions. Steel is known for its strength and durability, making it an ideal material for withstanding harsh weather elements such as high winds, heavy rain, snow, and extreme temperatures. Steel sheets are often used in construction, roofing, and outdoor applications where they are exposed to various weather conditions. Additionally, steel sheets can be coated with protective layers such as galvanized or painted finishes, which further enhance their resistance to corrosion and weathering. Overall, steel sheets are highly reliable and can endure extreme weather conditions with minimal damage or deterioration.

- Q: Can steel sheets be customized according to specific requirements?

- Indeed, it is possible to customize steel sheets to meet specific requirements. Steel manufacturers possess the capacity to manufacture steel sheets in different sizes, thicknesses, and finishes, catering to the unique needs of customers. The customization options extend to include specific alloy compositions, surface treatments, and mechanical properties. By employing cutting, shearing, bending, and shaping techniques, steel sheets can be tailor-made to fit precise dimensions and shapes, suitable for various applications. Furthermore, manufacturers can also accommodate personalized branding, labeling, and packaging preferences as dictated by the customer. In conclusion, steel sheets offer a remarkable degree of flexibility and can be readily customized to satisfy specific requirements.

- Q: What are the different thickness options for steel sheets?

- The thickness options for steel sheets vary depending on the specific application and industry requirements. Common thickness options for steel sheets range from thin gauges, such as 26 gauge (0.0179 inches) or 30 gauge (0.0120 inches), to thicker gauges, such as 16 gauge (0.0598 inches) or 10 gauge (0.1345 inches). However, it is important to note that steel sheets can be customized to meet specific thickness requirements beyond these standard options.

- Q: What is the electromagnetic steel plate in the generator?

- As the core material, the magnetic conductivity is the core.As for the protection of heat resistant copper wire, the argument is not very good, because under normal circumstances, copper heat than iron core heat greater.

- Q: What is the process of cutting steel sheets?

- The process of cutting steel sheets typically involves using specialized tools such as shears, plasma cutters, or laser cutters to precisely trim and shape the steel material according to specific measurements or design requirements. These tools apply intense heat, force, or a combination of both, to cut through the steel sheets, creating clean and accurate cuts. It is crucial to follow proper safety protocols and use appropriate equipment to ensure efficient and precise cutting of steel sheets.

Send your message to us

EPS Roof Sandwich Panel/Polystyrene Foam Sandwich Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 25000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords