EPDM Waterproof Membrane Manufacturer with 15-year Experience

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction:

This waterproof coiled material is of high elasticity with best performance among high polumer

waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylene-propylene rubber is produced withthe use of the most advanced contiuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,perfomances reach or exceedthe demands of GB18173.1-2000 standard.

2. Product Specification:

There are two installation ways.one is full sticking,the other is hot welding.

Thick | 1.0mm,1.2mm,1.5mm,2.0mm,3.0mm or others |

Width | 1m to 4m |

Length | 20m |

Model | EPDM, EPDM with fabric |

3. Technical Sheet for EPDM Waterproof Membrane:

Number | Item | Unit | Value | |

1 | Size Variation | Thichness | % | ±10 |

Width | % | ±1 | ||

Length | % | Allowed negative | ||

2 | Breaking tensile strength at normal temperature | Mpa | ≥7.5 | |

Breaking tensile strength at 70°C | Mpa | ≥2.3 | ||

3 | Breaking elongation at normal temperature | % | ≥450 | |

Breaking elongation at -20°C | % | ≥200 | ||

4 | Tear strength | KN/m | ≥25 | |

5 | Impermeability(30min) | * | 0.3Mpa no leakage | |

6 | Bending at low tempreture | °C | ≤-40 | |

7 | Stretch tensor at heating | Elongate | mm | ≤2 |

Shrink | mm | ≤4 | ||

8 | Air oven aging(80°C×168h) | Tensile strength at break retained | % | ≥80 |

Elongation at break retained | % | ≥70 | ||

9 | Anti-alkali | Tensile strength at break retained | % | ≥80 |

Elongation at break retained | % | ≥80 | ||

10 | Nuture weathing at manual simulation | Tensile strength at break retained | % | ≥80 |

Elongation at break retained | % | ≥70 | ||

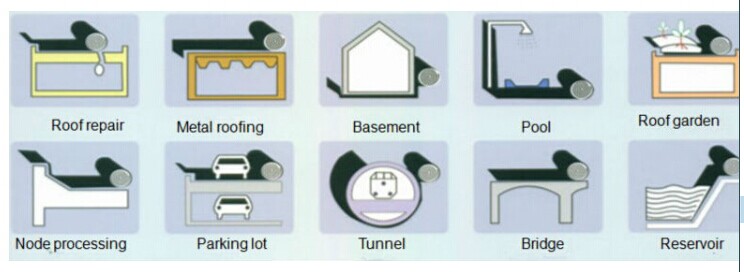

4. Product Application:

EPDM waterproof membranes form an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway & tunnel, water conservancy such as water pools & ditch, shelter, grain depot, land filling, dyke and subway.

5. Some photos:

- Q: Can a waterproofing membrane be used in areas with extreme weather conditions?

- Indeed, in regions with severe weather conditions, one can employ a waterproofing membrane. Designed to safeguard against water infiltration, these membranes possess the ability to endure various climatic extremes, encompassing scorching heat, freezing cold, torrential downpours, and snowfall. Composed of sturdy materials, these membranes exhibit resistance to UV radiation, fluctuations in temperature, and other environmental elements. Furthermore, certain waterproofing membranes are specifically tailored for deployment in areas with harsh weather conditions, thereby bestowing superior performance and longevity. It is crucial to select a waterproofing membrane that aligns with the distinct weather conditions of the vicinity in order to guarantee enduring and effective protection.

- Q: Are waterproofing membranes resistant to sulfuric acid exposure?

- Waterproofing membranes are generally not resistant to sulfuric acid exposure. Sulfuric acid is a highly corrosive substance that can cause severe damage to many materials, including waterproofing membranes. Due to the strong acidic nature of sulfuric acid, it can react with and degrade the membrane, leading to its failure. Therefore, if there is a possibility of sulfuric acid exposure, it is important to use acid-resistant materials specifically designed to withstand such corrosive substances.

- Q: Can a waterproofing membrane be used for a parking garage deck protection?

- Indeed, the utilization of a waterproofing membrane is a viable option for safeguarding the parking garage deck. Designed with the specific purpose of preventing water infiltration and shielding the underlying structure from moisture-related harm, a waterproofing membrane proves to be highly effective in such scenarios. When applied to the parking garage deck, the waterproofing membrane acts as a barrier, effectively preventing water from permeating the concrete and reaching the steel reinforcement beneath. This, in turn, mitigates the risk of corrosion and deterioration, ultimately prolonging the lifespan of the structure and minimizing the need for expensive repairs or replacements. Moreover, the waterproofing membrane offers protection against other potential sources of damage, including oil or chemical spills resulting from vehicular activity. By creating a barrier, it successfully hinders these substances from penetrating the concrete and causing unsightly stains or deterioration. Supplementary to its protective capabilities, the waterproofing membrane enhances the overall durability and strength of the parking garage deck. It aids in the reduction of cracking, spalling, and other forms of concrete damage that may arise due to freeze-thaw cycles, temperature fluctuations, or heavy loads. All in all, opting for a waterproofing membrane to safeguard the parking garage deck is a highly recommended solution for ensuring the longevity and structural integrity of the facility. By providing a dependable defense against water infiltration, chemical spills, and other potential sources of damage, it serves to decrease maintenance expenses and extend the lifespan of the parking garage deck.

- Q: Can a waterproofing membrane be applied to existing structures or is it only suitable for new construction?

- A waterproofing membrane has the capability to be applied to both existing structures and new construction. These membranes are specifically designed to create a barrier against water infiltration, making them suitable for preventing water damage in various areas such as roofs, basements, and foundations. Whether it is an aged building or a recently constructed one, the application of a waterproofing membrane can effectively maintain the dryness of the structure and prevent problems associated with moisture, such as leaks, seepage, and mold growth. However, when applying a waterproofing membrane to an existing structure, it may be necessary to undertake additional preparation and surface treatment in order to ensure proper adhesion and efficiency. It is strongly advised to seek the guidance of an experienced waterproofing contractor who can evaluate the specific requirements of the structure and provide suitable solutions.

- Q: Can a waterproofing membrane be used for a school building foundation?

- A school building foundation can indeed utilize a waterproofing membrane. These membranes are specifically created to safeguard structures by preventing water from infiltrating. They are commonly employed in various construction scenarios, including building foundations. By applying a waterproofing membrane to the foundation walls, it can effectively shield the building from water-related harm and prevent issues caused by moisture, such as mold, decay, and structural damage. This is especially crucial for school buildings due to their extensive foundations and the possibility of heavy usage and water exposure. Thus, the use of a waterproofing membrane is a viable solution to ensure the durability and structural soundness of the school building foundation.

- Q: How does a waterproofing membrane handle hydrostatic pressure?

- Hydrostatic pressure is managed by a waterproofing membrane, which acts as a barrier between water and the structure it is applied to. When faced with hydrostatic pressure, the membrane creates a seamless seal that stops water from entering the structure. The membrane is constructed to be impermeable, meaning it does not allow water molecules to pass through. Typically made from rubber, PVC, or bitumen, these materials have excellent resistance to water penetration. They are also flexible, enabling the membrane to conform to the surface it is applied to and create a secure seal. When the membrane experiences hydrostatic pressure, it withstands the force and prevents water from infiltrating the structure. The membrane's ability to resist water pressure depends on its thickness, strength, and installation quality. Thicker membranes offer greater resistance to hydrostatic pressure, while a well-installed membrane without gaps or overlaps enhances its effectiveness in managing water pressure. In addition to acting as a barrier against water penetration, some waterproofing membranes are designed to accommodate movement caused by hydrostatic pressure. They can stretch or elongate to accommodate the structure's expansion and contraction, which occurs due to varying water levels or external forces. This flexibility helps the membrane maintain its integrity and prevent water from seeping through. Overall, a waterproofing membrane effectively handles hydrostatic pressure by providing a continuous, impermeable barrier that resists the force of standing or moving water and prevents it from infiltrating the structure. Its ability to withstand water pressure depends on its thickness, strength, installation quality, and flexibility to accommodate movement.

- Q: Can a waterproofing membrane be used on precast stone block surfaces?

- Yes, a waterproofing membrane can be used on precast stone block surfaces. Waterproofing membranes are commonly used to prevent water penetration and moisture damage in various types of surfaces, including precast stone blocks. These membranes are designed to create a barrier against water, preventing it from seeping into the surface and causing issues such as mold, deterioration, or structural damage. Applying a waterproofing membrane to precast stone block surfaces can help enhance their durability and longevity by protecting them from water-related problems. However, it is important to carefully follow the manufacturer's instructions and ensure that the chosen waterproofing membrane is suitable for the specific type of precast stone block surface being treated.

- Q: Can a waterproofing membrane be used for a tunnel waterproofing system?

- A tunnel waterproofing system can utilize a waterproofing membrane. This material, which is both flexible and durable, is specifically designed to prevent water from entering a structure. It is commonly employed in various construction projects, including tunnels, to create a strong defense against water infiltration. In the case of a tunnel waterproofing system, the membrane is typically applied to the outer walls and floor of the tunnel. Multiple layers are installed to guarantee a tight seal and long-lasting protection against water penetration. By acting as a barrier, the membrane effectively prevents water from seeping through the tunnel's concrete or other materials. Different types of waterproofing membranes are available, such as bituminous, PVC, and liquid-applied membranes. The appropriate choice depends on factors such as the type of tunnel construction, water pressure levels, and project-specific requirements. To ensure the membrane's effectiveness, it is crucial to carefully select and install it. Proper surface preparation, including substrate cleaning and smoothing, is essential for achieving a strong bond between the membrane and the tunnel surface. Additionally, great attention should be paid to correctly sealing any joints, penetrations, or connections in the membrane to prevent water from entering. Overall, a waterproofing membrane is a dependable and widely utilized solution for tunnel waterproofing systems. When appropriately chosen and installed, it provides an effective defense against water ingress, guaranteeing the tunnel structure's durability and longevity.

- Q: Can a waterproofing membrane prevent leaks from occurring?

- Yes, a waterproofing membrane is specifically designed to prevent leaks from occurring by providing a protective barrier against water intrusion. It acts as a waterproof layer that helps to seal and protect various surfaces, such as roofs, foundations, and basements, from water penetration and potential leaks.

- Q: SBS waterproofing membrane sub-class I and II when to use what level to use a secondary level

- SBS modified asphalt waterproofing membrane, this coil has a good high temperature performance, can be -25 to +100 ℃ temperature range of use, a higher flexibility and fatigue resistance, and up to 1500% Elongation and strong puncture resistance, tear resistance. Suitable for cold areas, as well as deformation and vibration of large industrial and civil buildings waterproofing works.

Send your message to us

EPDM Waterproof Membrane Manufacturer with 15-year Experience

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords