EPDM Waterproof Membrane in 1.5mm with Fleeced Back

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane in 1.5mm with Fleeced Back

Description Of EPDM Waterproof Membrane in 1.5mm with Fleeced Back:

We have more than 15 years experience in development & manufacture construction materials such as waterproof membrane,waterproof coils,waterproof panels,waterproof coating,geomembrane,geotextiles etc.Depending on our full set production line,well equipped laboratory,cooperation with institute&college and experienced employees,we have successfully developed and consolidated domestic and foreign market.With a high-tech team of research and development,we have our patent technology, the spray application waterproof membrane.They are the most advanced technology in tunnel and underground projects.Quality is our life,customer satisfaction is our goal, to build the world be more beautiful is our responsibility!

Main Features of EPDM Waterproof Membrane in 1.5mm with Fleeced Back:

1.Excellent anti aging performance ,service life up to 50 years.

2.High extension rate,high tensile strength ,small size changes at heat treatment.

3.Good plant roots penetrability resistance and can be made waterproofing layer of planting roof.

4.Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem.

5.Good low temperature flexibility ,and good performance of adapting to ambient temperature changes.

6.Convenient application ,solid joint ,no environment pollution.

7.Chemical corrosion resistance ,can be used for special occasions.

8.Good anti-perforated.

Specifications of EPDM Waterproof Membrane in 1.5mm with Fleeced Back:

| Material | EPDM Rubber |

| Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

| Thick | 1.2mm, 1.5mm, 2.0mm |

| Type | Vulcanized & Weldable |

| Pattern | Non-reinforced (homogeneous) |

| Certificate | ISO9001/14001 |

Applications of EPDM Waterproof Membrane in 1.5mm with Fleeced Back:

1. Roofs, Basement, Toilet

2. Industrial and civil building waterproofing

3. Geo-synthetic liner for swimming pool, channels, irrigation system

4. Especially suit for projects with high requirements in durability, anti-corrosion and deformation

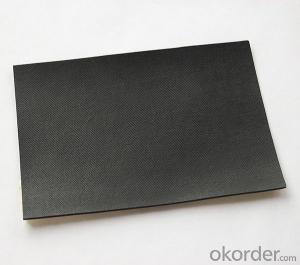

IMages of EPDM Waterproof Membrane in 1.5mm with Fleeced Back:

FAQ of EPDM Waterproof Membrane in 1.5mm with Fleeced Back:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used for a balcony deck coating?

- Yes, a waterproofing membrane can be used for a balcony deck coating. Waterproofing membranes are often used to protect and seal balconies and decks from water damage, providing a durable and long-lasting solution.

- Q: Can a waterproofing membrane be used for elevator shafts?

- A waterproofing membrane is an effective solution for elevator shafts. Elevator shafts are prone to water infiltration, which can harm the building's structure and the elevator system itself. By using a waterproofing membrane, water can be prevented from entering the shaft, safeguarding it against moisture-related issues such as corrosion, mold, and mildew. Typically, the membrane is applied to the shaft's walls and floors, creating a barrier that blocks water. To ensure optimal effectiveness and durability, it is important to select a waterproofing membrane specifically designed for elevator shafts. Moreover, proper installation and maintenance are crucial for the long-term performance of the waterproofing system. In conclusion, employing a waterproofing membrane for elevator shafts is a recommended measure to shield against water damage and uphold the elevator system's functionality and safety.

- Q: Are there any specific considerations for installing a waterproofing membrane on stucco surfaces?

- Yes, there are several specific considerations to keep in mind when installing a waterproofing membrane on stucco surfaces. Firstly, it is important to ensure that the stucco surface is clean and free of any dirt, debris, or loose material before applying the waterproofing membrane. This can be done by power washing or scrubbing the surface with a stiff brush and water. Secondly, it is crucial to choose the right type of waterproofing membrane that is suitable for stucco surfaces. There are various options available in the market, such as liquid-applied membranes, sheet membranes, or peel-and-stick membranes. It is essential to select a membrane that is compatible with stucco and provides a strong and durable barrier against water penetration. Another consideration is the proper application technique. The membrane should be applied evenly and smoothly, ensuring complete coverage over the entire stucco surface. It is important to follow the manufacturer's instructions and guidelines for the specific membrane being used. Additionally, it is recommended to pay attention to the details and transitions, such as around windows, doors, vents, or other penetrations. These areas are more prone to water infiltration, so it is important to properly seal and waterproof these vulnerable points using additional techniques or products, like flashing or caulking. Furthermore, it is essential to consider the climate and weather conditions in the area. If the stucco surface is exposed to extreme temperatures or frequent freeze-thaw cycles, it is advisable to choose a waterproofing membrane that can withstand these conditions and provide long-lasting protection. Lastly, regular inspection and maintenance of the waterproofing membrane is crucial to ensure its effectiveness over time. It is recommended to periodically check for any signs of damage, such as cracking, peeling, or bubbling, and promptly address any issues to prevent water infiltration and potential damage to the stucco surface. In conclusion, when installing a waterproofing membrane on stucco surfaces, it is important to clean the surface, choose the right type of membrane, apply it correctly, pay attention to details and transitions, consider the climate, and regularly inspect and maintain the membrane for long-lasting protection against water penetration.

- Q: Can a waterproofing membrane be used for water tanks or reservoirs?

- Yes, a waterproofing membrane can be used for water tanks or reservoirs. Waterproofing membranes are designed to create a barrier that prevents water from penetrating through the surface. They are commonly used in various applications, including water tanks and reservoirs, to ensure that the stored water remains contained and does not leak or seep into the surrounding environment. The membrane is typically applied on the interior surface of the tank or reservoir, providing a durable and watertight seal. This helps to maintain the integrity of the water storage system and prevent any potential water loss or contamination. Additionally, waterproofing membranes can also protect the tank or reservoir from corrosion and structural damage caused by water exposure, extending their lifespan. Therefore, using a waterproofing membrane is an effective solution for ensuring the safety and functionality of water tanks or reservoirs.

- Q: Does a waterproofing membrane have any impact on the appearance of a surface?

- Yes, a waterproofing membrane can have an impact on the appearance of a surface. When applied to a surface, such as a wall or floor, the waterproofing membrane creates a barrier that prevents water or moisture from penetrating the surface. This often involves applying a coating or layer that can alter the texture or sheen of the surface. In some cases, the membrane may cause a slight color change or darken the surface. However, there are also transparent or colorless waterproofing membranes available that do not significantly alter the appearance of the surface. Ultimately, the impact on appearance will depend on the type of waterproofing membrane used and the desired aesthetic outcome.

- Q: Is a waterproofing membrane resistant to punctures or tears?

- Yes, a waterproofing membrane is designed to be resistant to punctures and tears. It is specifically engineered to provide a durable barrier that can withstand potential damage from sharp objects or external forces.

- Q: Can a waterproofing membrane be used in saunas?

- Indeed, a sauna can utilize a waterproofing membrane. Given that saunas consist of environments abundant in moisture, implementing a waterproofing membrane can effectively avert water damage and shield the underlying structure against moisture infiltration. The membrane functions as a barrier, effectively impeding the permeation of water and mitigating potential complications like mold growth, mildew formation, and rot. The selection of a waterproofing membrane specifically engineered for high-moisture regions, capable of withstanding the intense heat and humidity characteristic of saunas, is of utmost importance. Additionally, proper installation and adherence to manufacturer guidelines are essential to guarantee the efficiency and durability of the waterproofing membrane within a sauna setting.

- Q: Can waterproofing membranes be used on below-grade parking structures?

- Below-grade parking structures can benefit greatly from the use of waterproofing membranes. They are frequently employed to safeguard these structures against water infiltration and potential harm. The main purpose of these membranes is to create a barrier that prevents water from penetrating the concrete and causing deterioration. To ensure the long-term durability and structural integrity of parking structures, the application of these membranes to the below-grade walls and floors is essential. Moreover, the use of waterproofing membranes also aids in the prevention of mold and mildew formation, which is a common problem in damp environments like below-grade parking structures. In conclusion, it is highly advisable to utilize waterproofing membranes in order to shield below-grade parking structures from water damage and prolong their lifespan.

- Q: Does a waterproofing membrane require any special considerations for installation in earthquake-prone areas?

- Yes, a waterproofing membrane does require special considerations for installation in earthquake-prone areas. In these areas, the ground is more susceptible to movement and shaking, which can significantly impact the integrity of the waterproofing system. Therefore, it becomes crucial to take additional precautions to ensure that the membrane is properly installed and capable of withstanding seismic activity. One important consideration is the selection of the waterproofing membrane itself. It is recommended to choose a membrane that has been specifically designed and tested to withstand seismic activity. These membranes are usually more flexible and have higher tensile strength to accommodate ground movement during earthquakes. Additionally, the installation process should be executed with utmost care and attention to detail. The membrane should be properly anchored or secured to the substrate using appropriate fasteners and adhesives. Reinforcement techniques such as the use of reinforcing fabric or mesh can also be employed to enhance the membrane's resistance to movement. Furthermore, it is essential to ensure that all seams and joints in the membrane are properly sealed and reinforced. Special attention should be given to areas that are more prone to movement, such as corners, edges, and penetrations. Using compatible and high-quality sealants or adhesives will help maintain the integrity of these vulnerable points. Regular inspections and maintenance are also crucial in earthquake-prone areas. Inspecting the membrane periodically for any signs of damage, such as cracks or separations, allows for early detection and timely repairs. Additionally, it is vital to have a contingency plan in place to address any potential damage that may occur during an earthquake, including emergency repair procedures. In summary, installing a waterproofing membrane in earthquake-prone areas requires careful consideration and adherence to specific guidelines. By selecting an appropriate membrane, properly anchoring and reinforcing it, ensuring proper sealing of seams and joints, and conducting regular inspections, the waterproofing system can be better prepared to withstand earthquakes and provide long-lasting protection against water intrusion.

- Q: Can a waterproofing membrane be used for dams?

- A waterproofing membrane is suitable for dams, which are constructions designed to retain water and form reservoirs. It is of utmost importance to guarantee that these structures are impenetrable to water to avoid leakage and potential harm. In the construction of dams, it is typical to utilize waterproofing membranes as a safeguard against water infiltration, which could lead to erosion or compromise the structural integrity. These membranes are typically composed of resilient materials like rubber or reinforced PVC, engineered to withstand water pressure and endure over time. Furthermore, the installation of a waterproofing membrane also aids in mitigating the potential risk of seepage and leakage in the dam, ensuring the overall structure's safety and efficacy.

Send your message to us

EPDM Waterproof Membrane in 1.5mm with Fleeced Back

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords