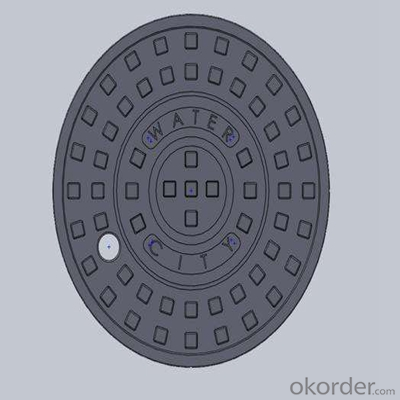

EN124 Precise Casting Ductile Cast Iron Double Seal Manhole Cover

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 3900 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1)Product information

Manhole Covers are manufactured for construction and public use. Manhole Covers shall be smooth and free from sand holes, blow holes, distortion or any other defects

2) Material

a) Ductile Iron GGG500-7 & 400-12

b) Grey Iron GG20

3) Designs

a) EN124 A15, B125, C250, D400, E600 and F900

b) A60005 for casting design

c) Major standards designs available

d) As per customers' drawings or samples

4) Process

c) Molding boards

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than.

Contain no metal and no recovery value, anti-theft.

Specifications

Double triangle ductile iron manhole cover

1.Standard:ISO 9001 EN124 D400

2.Service:OEM

3.High quality

4.Made of ductile

Our Company

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers.

FAQ

About Sample

Q : Can I get free samples?

A: Yes, we can provide you the free sample, but you have to bear the delivery costs.

About Customer Logo

Q: Can I have my own logo on the product?

A: Yes, you can send your logo design to us and send us the authority letter. Then we can cast the logo on body.

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Professional technical support with free charge.

5. After the cooperation: Any of your problem will be solved within 24 hours.

- Q: What are the casting parts used to test shrinkage holes?

- 2. x ray. This method can do nondestructive testing, but the cost is higher. Generally, high castings are required.

- Q: Why does the surface of stainless steel casting mirror mirror ripple?

- The surface can be improved by a little more than Xiasha

- Q: It is generally said that cast iron is re smelted by pig iron. My question is..:1 pig iron for melting iron, is directly cast into products (such as bed cover, etc.); or that is just the first pig iron smelting iron casting, such as to cover, bed and other products, will once again cast iron melt to casting?2, there are many castings to the engine. Are these castings made by the engine manufacturer themselves or bought by others?There is no need to answer all. Thank you!!!

- The molten iron (molten iron, scrap steel, scrap casting, iron alloy) is melted into cast iron by means of an electric furnace or cupola, and is poured into a casting.

- Q: What method of casting does not rust? I think the sample is like oil

- The surface of a general casting is easy to rust. In order to prolong the rusting period, antirust paint or antirust oil is usually sprayed. What you said should be anti rust oil.

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- Mainly because of the cooling shrinkage caused by internal stress caused. There is the change of temperature distribution in materials element imbalance, is typical of surface and internal, thin wall and thick wall, bottom and top.

- Q: What is the difference between casting and stamping parts?

- Cold stamping is generally no longer done by cutting, or only a small amount of cutting is required. The precision and surface state of hot stamping parts are lower than those of cold stamping parts, but they are better than those of castings and forgings, and the amount of cutting is less.Stamping is mainly based on process classification, can be divided into separation process and forming process two major categories.

- Q: My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- The common material that can be anodized is aluminum alloy. It is recommended to use casting aluminum alloys, such as ZL102 and ZL105, which are commonly used as cast aluminium alloys. The processing of aluminum casting is easy. After processing, the surface of the whole part can be anodized. The color can be chosen.

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- Cracks are considered serious levels of defects and should be repaired

- Q: Heat treatment process and purpose of casting parts

- Natural aging (also known as Chang Hua): lost in the open, the sun and rain, can have experienced years of wind and frost.

- Q: What's the cause of the choking of the casting?,

- Causes of choking fire:1., casting material in the pouring of gas;

Send your message to us

EN124 Precise Casting Ductile Cast Iron Double Seal Manhole Cover

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 3900 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords