Embossed Sheet Metal Panel for Auto Tool Case

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Embossed Sheet Metal Panel for Auto Tool Case

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

2. Application of Embossed Sheet Metal Panel for Auto Tool Case

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Embossed Sheet Metal Panel for Auto Tool Case

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

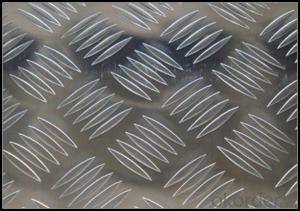

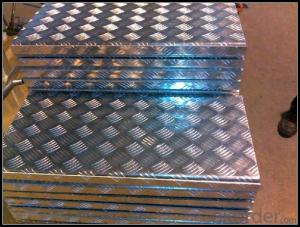

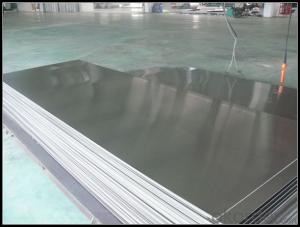

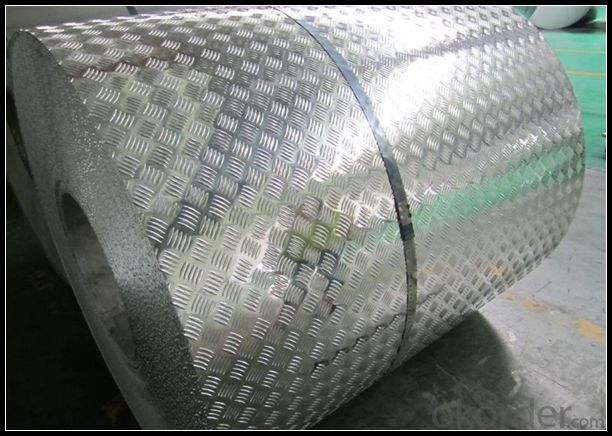

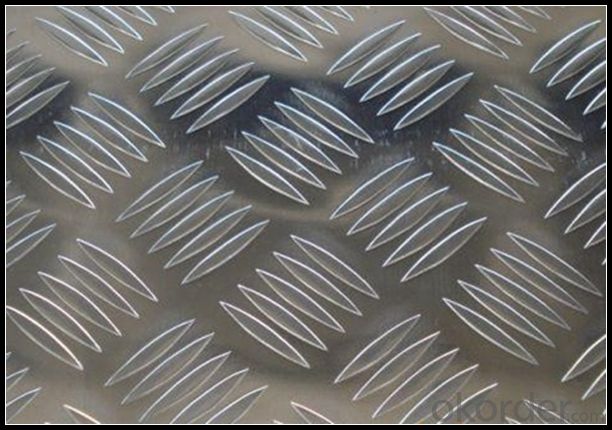

5. Image of Embossed Sheet Metal Panel for Auto Tool Case

6. Package and shipping of Embossed Sheet Metal Panel for Auto Tool Case

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: If one were to hit someone with a baseball bat, would it cause more pain to use a wooden bat or an aluminum one? Just wondering.

- The aluminum will hurt more with the reverberation that travels through the bat. Hence you see the rubber padding on the bat, along with wearing batting gloves. Would also sends some strong vibrations through the hands when the ball is struck in certain positions, however, catch a tough pitch with that aluminum without a batting glove and your hands will be stinging.

- Q: what's the temperature tolerance of aluminum sheets?

- aluminum is a kind of silver white metal,melting point:660.4℃, boiling point: 2467℃,density: 2.70 g/cm?,very light, about 1/4 of iron's density.it has low hardness and good ductility, which makes it suitable for being pulled into threadlets or pressed into aluminum foils, and the later is usually used for packaging candy and cigarette. it has good electrical and temperature conductivity. it's used for the manufacture of electric wire and cable in electric power industry, and for the manufacture of cooker in daily life bined with the magnesium , copper,zinc,tin,manganese,chromium,zirconium,silicon and other elments,it can formulate various alloys that is broadly used for the manufacture of airplane,car,ship, materials of daily living equipment and the doors and windows of construction industry.aluminum is one of the best reflectors of heat and light, so it is used as thermal insulation material and the manufacture of reflecting mirror in the reflecting telescope.

- Q: How do aluminum sheets perform in terms of thermal insulation?

- When it comes to thermal insulation, aluminum sheets are not efficient. Their high thermal conductivity allows heat to easily pass through them, making them ineffective in blocking or resisting heat transfer. As a result, their thermal insulation properties are poor. If your main concern is thermal insulation, it would be more appropriate to consider other materials like fiberglass, foam, or mineral wool as they would be better suited for the task.

- Q: Can aluminum sheets be used for elevator interiors?

- Indeed, elevator interiors can certainly be constructed using aluminum sheets. Aluminum has gained significant popularity as a material of choice for elevator interiors due to its multitude of advantageous qualities. Its lightweight nature, durability, and resistance to corrosion render it highly suitable for long-term utilization in elevator applications. With ease, aluminum sheets can be skillfully fabricated and shaped to perfectly fit the dimensions and design specifications of elevator interiors. Furthermore, aluminum can be enhanced with various types of coatings or finishes, such as anodizing or powder coating, to not only augment its aesthetic appeal but also provide additional protection. Overall, aluminum sheets represent a practical and widely utilized option for elevator interiors within the industry.

- Q: Are aluminum sheets suitable for aerospace fuel tanks?

- Yes, aluminum sheets are commonly used in the construction of aerospace fuel tanks due to their lightweight, corrosion-resistant, and strong properties.

- Q: How does the thermal conductivity of aluminum compare to other metals?

- Compared to many other metals, aluminum boasts a relatively high thermal conductivity. It is often hailed as one of the foremost heat conductors among common metals. With a thermal conductivity of approximately 205 watts per meter kelvin (W/m·K), aluminum surpasses copper (about 401 W/m·K) and even silver (about 429 W/m·K). As a result, aluminum excels at efficiently transferring heat, making it a widely favored option for heat sinks, radiators, and various applications necessitating effective heat dissipation. Nonetheless, it is worth mentioning that certain metals, such as diamond and graphene, surpass aluminum in terms of thermal conductivity.

- Q: What are the different methods of surface cleaning for aluminum sheet?

- Different methods exist for cleaning aluminum sheets, each with unique advantages and suitability for various situations. Common methods include: 1. Mechanical Cleaning: Scrubbing the aluminum sheet with abrasive materials like sandpaper or wire brushes can physically eliminate dirt, oxidation, or other contaminants. Although effective for removing severe stains or corrosion, this method may cause scratches. 2. Chemical Cleaning: Utilizing cleaning agents or solvents, chemical cleaning dissolves and eliminates dirt, grease, or oxidation from the aluminum sheet. Depending on requirements, the cleaning agents can be acidic, alkaline, or neutral. This method is ideal for removing light stains or surface oxidation and is suitable for large-scale cleaning operations. 3. Electrolytic Cleaning: By immersing the aluminum sheet in an electrolyte solution and applying a direct current, electrolytic cleaning uses electricity to dissolve and separate contaminants from the surface. This method is effective for eliminating heavy oxidation, corrosion, or stubborn stains. 4. Ultrasonic Cleaning: Placing the aluminum sheet in a tank filled with a cleaning solution and subjecting it to high-frequency sound waves, ultrasonic cleaning creates tiny bubbles that dislodge dirt particles upon contact with the sheet's surface. It is suitable for removing fine particles, oils, or grease. 5. Steam Cleaning: High-pressure steam is employed in steam cleaning to remove dirt, grime, or contaminants from the aluminum sheet's surface. The steam's high temperature and pressure break down dirt particles and sanitize the sheet. This method effectively removes oils, greases, or organic residues. When selecting a cleaning method for aluminum sheets, factors such as the type and severity of contamination, desired cleanliness level, and specific application requirements must be considered. Additionally, it is crucial to follow safety guidelines and use appropriate protective equipment when handling cleaning agents or working with electrical equipment.

- Q: What are the standard sizes and availability of aluminum sheets in the market?

- The standard sizes and availability of aluminum sheets in the market can vary depending on the location and specific requirements. However, there are some commonly available sizes that can generally be found in most markets. In terms of thickness, aluminum sheets are commonly available in 0.02 to 0.2 inches (0.5 to 5 millimeters) thickness range. Thinner sheets (0.02 to 0.06 inches) are often used for lightweight applications such as signage or crafts, while thicker sheets (0.1 to 0.2 inches) are typically used for more heavy-duty applications like construction or industrial purposes. Regarding width and length, standard aluminum sheet sizes are often offered in 4 feet by 8 feet (48 inches by 96 inches) or 4 feet by 12 feet (48 inches by 144 inches). These dimensions are widely available and suitable for various applications. However, it's important to note that custom sizes can also be ordered or cut from larger sheets to meet specific project requirements. Availability of aluminum sheets can be found in various locations, including local hardware stores, metal suppliers, and online marketplaces. It is always recommended to check with local suppliers or conduct online research to determine the specific sizes and availability in your area. Additionally, different grades or alloys of aluminum may have varying availability, so it's essential to consider the specific requirements of your project when sourcing aluminum sheets.

- Q: 4.0mm five bars, aluminum plate, 4 aluminum plate, one ton, how many square?

- The square and the thickness are multiplied, and then multiplied by the density is the weight, and then by weight conversion on it

- Q: This question asks for various methods through which aluminum sheets can be recycled and repurposed.

- <p>Aluminum sheets can be recycled and reused in several ways: 1. Melting and Reformation: The most common method is to melt down the aluminum and reform it into new products. 2. Mechanical Recycling: This involves shredding and compacting the aluminum sheets to be used as raw material in new products. 3. Energy Recovery: The heat generated from burning aluminum can be used to produce energy. 4. Alloying: Aluminum can be combined with other metals to create new alloys with different properties. 5. Reuse in Construction: Aluminum sheets can be reused in construction projects, such as facades or roofing. 6. Manufacturing: They can be used in manufacturing processes to create new aluminum products like cans, foils, and automotive parts. Proper recycling of aluminum reduces environmental impact and conserves resources.</p>

Send your message to us

Embossed Sheet Metal Panel for Auto Tool Case

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords