Electronical Hot Rolled Galvanized Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Electronical Hot Rolled Galvanized Steel

1、QUALITY

GB/T343 and other standards.

2、 ZINC COATING

GB/T15393 and other standards.

3、RAW MATERIAL

A、WIRE ROD: 1006、1008、1018、Q195

ZINC WITH 99.995% purity.

4、TENSILE STRENGTH RANGE

(mm)size | (mpa)tensile strength |

0.24—1.60 | 290--550 |

1.61—5.00 | 400--1200 |

5、APPLICATION

Detonator lead、artware、 redrawing, toy, etc.

6、Packing

(mm) size | Coil size | Spool packing | big coil packing | |

(mm)ID | (mm)OD | |||

0.24—0.45 | 8 | 1—100㎏ | ||

0.46—0.60 | 8、12 | 1—100㎏ | ||

0.61—1.60 | 12、14、16 | 1—100㎏ | 250-400 | 400-770 |

1.61—5.00 | 450 | 800 | ||

7、 ZINC COATING

mm SIZE | (g/㎡)Min. zinc coating | |||||||

A | AB | B | C | D | E | F | ||

A1 | B2 | |||||||

≤0.25 | 18 | 15 | 12 | 5 | ||||

〉0.25-0.40 | 25 | 20 | 12 | 5 | ||||

〉0.40-0.50 | 25 | 20 | 15 | 8 | ||||

〉0.50-0.60 | 25 | 20 | 15 | 8 | ||||

〉0.60-0.80 | 20 | 15 | 10 | |||||

〉0.80-1.20 | 25 | 18 | 10 | |||||

〉1.20-1.60 | 25 | 18 | 12 | |||||

〉1.60-1.80 | 100 | 70 | 40 | 30 | 20 | |||

〉1.80-2.20 | 105 | 80 | 50 | 40 | 20 | |||

〉2.20-2.50 | 110 | 80 | 55 | 40 | 25 | |||

〉2.50-3.00 | 120 | 90 | 70 | 45 | 25 | |||

〉3.00-4.00 | 100 | 85 | 60 | 30 | ||||

〉4.00-5.00 | 110 | 95 | 70 | 40 | ||||

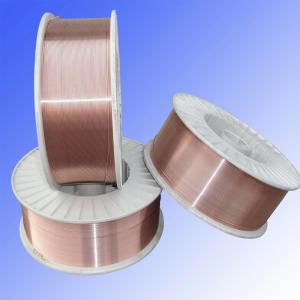

Picture

- Q: What are the different types of steel pipes and tubes available?

- There are several different types of steel pipes and tubes available, including seamless, welded, galvanized, stainless steel, and carbon steel pipes. Each type has its own unique properties and uses, making them suitable for various applications in industries such as construction, plumbing, oil and gas, and manufacturing.

- Q: What are the factors to consider when choosing the right steel product for a specific application?

- When choosing the right steel product for a specific application, there are several factors to consider. These include the strength and durability required for the application, the corrosion resistance needed, the temperature and environmental conditions it will be exposed to, the desired appearance or finish, the cost, availability, and ease of fabrication of the steel product. Additionally, other factors such as weight, size, and compatibility with other materials in the application should also be taken into account.

- Q: How does steel pipe threading work?

- Steel pipe threading is a process used to create threads on the ends of steel pipes. It typically involves using a die and a threading machine to cut the desired threads onto the pipe. The die is placed on the pipe and then the machine rotates the pipe while the die cuts the threads into the surface. This creates a threaded section on the pipe that can be used to connect it with other pipes or fittings. Threading is commonly used in various industries, including plumbing and construction, to ensure tight and secure connections between steel pipes.

- Q: How does steel sheet metal fabrication work?

- Steel sheet metal fabrication involves the process of shaping and manipulating steel sheets into desired forms and structures using various techniques such as cutting, bending, and assembling. This is typically done through the use of specialized machinery and tools, such as laser cutters, press brakes, and welders. The steel sheets are first cut into the required shape, either manually or through automated processes. Then, they are bent or formed using press brakes to achieve the desired angles or curves. Finally, the individual parts are assembled together through welding, fastening, or other joining methods, resulting in a finished steel sheet metal product.

- Q: What are the maintenance and care requirements for different steel products?

- The maintenance and care requirements for different steel products can vary depending on their specific use and environment. However, in general, steel products should be regularly cleaned and inspected for any signs of damage or corrosion. This can be done by using mild soapy water and a soft cloth or sponge to remove dirt or grime. It is important to avoid using abrasive cleaners or tools that could scratch or damage the steel surface. Additionally, applying a protective coating, such as a wax or oil-based product, can help prevent rust and corrosion. Regular inspections should also be carried out to identify and address any issues promptly. Overall, proper maintenance and care can help extend the lifespan and ensure the optimal performance of steel products.

- Q: What are the properties of galvanized steel?

- Galvanized steel is a type of steel that has been coated with a layer of zinc, which provides several properties. It offers enhanced corrosion resistance, as the zinc layer acts as a barrier against rust and other forms of degradation. Additionally, galvanized steel has superior durability and longevity due to its protective zinc coating. This type of steel is also known for its high strength and excellent formability, making it suitable for various applications in construction, automotive, and manufacturing industries. Furthermore, galvanized steel is relatively low-maintenance and requires minimal upkeep.

- Q: What are the factors that affect the price of steel products?

- There are several factors that affect the price of steel products, including the cost of raw materials such as iron ore and coal, as well as the cost of energy and transportation. Additionally, market demand and supply dynamics, global economic conditions, and currency exchange rates can also impact steel prices. Furthermore, trade policies, tariffs, and government regulations can influence the price of steel products in different regions.

- Q: What are the different types of steel fittings and their uses?

- There are various types of steel fittings used in different industries. Some common types include steel elbows, steel tees, steel reducers, steel couplings, and steel flanges. Steel elbows are used to change the direction of a pipeline, steel tees are used to split or combine flow, steel reducers are used to connect pipes of different sizes, steel couplings are used to join pipes together, and steel flanges are used to connect pipes or valves to other equipment. These fittings are crucial in ensuring the proper flow, connection, and functionality of steel pipelines in various applications such as plumbing, oil and gas, chemical, and construction industries.

- Q: What are the properties of abrasion-resistant steel for industrial equipment?

- Abrasion-resistant steel for industrial equipment possesses several key properties. Firstly, it is extremely durable and can withstand repeated exposure to abrasive substances and environments without getting damaged or worn out easily. Secondly, it has a high hardness level, which enhances its resistance to abrasion and prevents any surface damage. Additionally, this type of steel is often corrosion-resistant, ensuring its longevity and performance in various industrial settings. Lastly, abrasion-resistant steel can be easily fabricated and machined, allowing for customization and easy integration into different equipment designs.

- Q: What are the different types of steel shelving and storage systems available?

- There are several different types of steel shelving and storage systems available, including boltless shelving, wire shelving, pallet racking, and mezzanine systems. Each type has its own unique features and benefits, making them suitable for various storage needs. Boltless shelving is easy to assemble and adjust, wire shelving allows for better visibility and air circulation, pallet racking is ideal for storing large and heavy items, and mezzanine systems provide additional storage space by utilizing vertical space in a warehouse or facility.

Send your message to us

Electronical Hot Rolled Galvanized Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords