eco-friend wood plastic composite wall panel wpc cladding

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | Engineered Flooring | Place of Origin: | Beijing China (Mainland) | Brand Name: | CMAX |

| Model Number: | CMAX H150H25 | Technics: | Wood-Plastic Composite Flooring | use: | landscape |

| COLOR: | different color for choice | length: | 2.2m~6m | width: | 100mm~250mm |

| thickness: | 10mm~40mm |

Packaging & Delivery

| Packaging Detail: | REGULAR EXPORTING PACKAGE |

| Delivery Detail: | 15DAYS |

Specifications

10years warranty;

10days delivery time;

more flexible payment terms;

thousands of mould for choice.

STOCK FROM CHILE WAREHOUSE

STOCK FROM DUBAI LOGISTICS CENTER

BID FOR BIG CONSTRUCTION PROJECT

1> What is WPC?

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

2> What’s WPC used for?

WPC can be used for military equipment, urban utilities and landscaping, architecture,

gymnasiums, outdoor decking, fencing, pallets, indoor and outdoor decoration.

3> Why choose WPC decking?

*Natural colour

*Slip resistant

*Resistance to water, rot and crack

*Guaranteed to last

*Low maintenance

*Beautiful and broad range of finish

4> What are the main kinds of WPC currently?

*WPC decking board

*DIY decking board

*WPC wall panel (wall cladding)

*Garden fence (railing)

*WPC outdoor furniture (gazebo, pavilion, outdoor desk&chair, dustbin, pet house…)

5> Ingredients of WPC?

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

6> Specification of WPC?

A. Weatherability

suitable from -40° C to +60° C, UV resistance

B. Test Data

| Testing Item | Technical Requirements | Value of Test |

| Water Content % | ≤2 | 0.4 |

Rockwell Hardness (HRR) | ≥60 | 80 |

Thickness Swelling after Water Absorption (%) | ≤1 | 0.2 |

Screw Holding | Surface of board ≥1300 | 3870 |

| End of board ≥1200 | 3460 | |

Static Bending | ≥20 | 28 |

Bending Elastic | ≥1800 | 4610 |

Abrasion | ≤0.08 | 0.06 |

Hammer falling impact in low temperature, broken (pcs) | ≤1 | 1 |

State after Heating | No babbles, cracks and pockmarks | - |

Rate of Size Change with Heating (%) | ±2.5 | -0.38~-0.45 |

Report Number: 201107126

Type of sample: 90x25x820mm, Solid

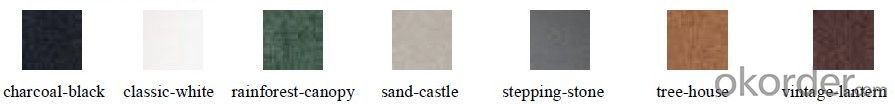

C. Main colors available:

charcoal-black; classic-white; rinforest-canopy;sand-castle; stepping-stone; tree-house; vintage-lantern .

- Q: What is the price?

- From the stability of the said, solid wood rafts to eliminate cough sarcastic tongue blasting compound film than solid wood flooring slightly better, but in the hearts of people, solid wood flooring is "composite", not the solid wood flooring as is the "whole Block "made of wood - there is some kind of complex. The advantages of solid wood flooring, foot feel good, look style, noble. But the solid wood flooring also has its flaws, in terms of thermal expansion and contraction, certainly no solid wood composite floor is good. Price, solid wood flooring generally in the 300 yuan from top to bottom, cheap, I am afraid there is a problem; and the price of solid wood flooring, if the price of solid wood flooring and the same, then the quality of the solid wood flooring is very good. However, if you want to shop wood flooring, it is recommended not to distinguish between living room and bedroom, so that both convenient for construction, but also gives the overall feeling.

- Q: Pink wall with what color of the floor was warm it

- This feeling do not know you like the West, I personally prefer, warm and not dazzling color.

- Q: I am considering buying a home Illinois. Unfortunately my price range is small; however there is a home my girlfriend and I love. The floors are slanted because the foundation has sunk because it’s a 100 or more year old home. Is there a way to fix the floors by adding more plywood or something to the lower part of the floor?

- Just from the experience of selling a rental property with settling, or slanted floors, I was told the man was going to brace the existing floor and then go over the area with an entirely new floor. He said trying to move the floor upward could cause problems with the existing walls. I would talk to one or more contractor to get an idea of what your individual situation might be. If it is normal settling, it's one thing, but I knew somone that bought a house that had been on a really old area of land fill, which should have been settled long before, and they ended up with slanted floors. They sold the house because that was a real mess.

- Q: Hey guys i wanna know which are the types of domestic floor finishes..im doing a report on them so can you please include a website for me to check out

- what kind of domestic floor finish are you expecting to get? Well if you want it shining without spendin too much money, try to use any regular wood polisher available in any market: Use a humid rag with some wood polisher every week and watch it glowing after a few weeks.It works !

- Q: Does anyone have any experience with painting a wood floor white? How did it come out and how long did it last? Did it get dirty very fast?

- I have painted some floors in my time. They can hold up if done properly. Any floor gets dirty depending on any number of factors. If you choose to try it here is the answer I provided to a similar question . Sanding first is the best way to start. Make sure you vacuum with the brush attachment on your vacuum cleaner and then wipe with a tack cloth or a clean white cotton rag dampened with paint thinner or mineral spirits. If you cannot deal with the dust wiping with a deglosser will work (check your local hardware/paint store). As suggested an oil base primer is the next best step (although there are some quality latex primers on the market). A topcoat of either an oil base or latex floor and porch paint is recommended (they come in colors including white). The oil base will take the wear better. The latex finish will eventually wear down leaving an eggshell like finish. Some people prefer this look. If you use latex you can put a polyurethane clear coat over it to add durability. However, it will also make the floor slicker, much like wax. Be careful how you clean your floor. Paint normally takes thirty days to cure and should not be cleaned the first week. After one week a mild soap and water cleaning is alright. Solvent and abrasive cleaners should never be used.

- Q: ok so my hubby and i just bought a 6 bd 2 bath house.. only problem is the down stairs bathroom floor looked as if the sub floor was bad right by the bathtub well hubby and i pulled up all the sub floor.. well the joist i think it is called there is 3 of them going across one of them when i step on it moves just a tiny bit(im 133 lbs) the 2nd one moves up and down when i step on it and has a split in the middle the 3rd one where the bath tub was is the worse and its soft feeling on the top and feels like it could break.. i was told by a repair man that to fix this problem it would cost WELL over 1,000.. i pulled up the other sub floor in the laundry room that is right next to the bathroom and only separated by a "wall" more like paneling and them joist seem to be fine(no splits,doest move much at all)what should i do and can this be fixed for less the 1,000??thanks

- I okorder /

- Q: So we recently redid the floors in the kitchen and the stairs leading to the 2nd floor. It's a different type of wood from the rest of the floors, and my 7 or 8 year old Australian Shepherd mix has been having a LOT of trouble with it. She has been slipping up a bit here and there, but then she flat-out fell, and I've banned her from going upstairs. She hurt her legs (old bones) a while back, and she's almost completely better. During that time we redid the floors and she wasn't allowed to go upstairs. Now we were going to allow her to go upstairs, but I'm too afraid that she'll slip and fall. We cannot get carpet runners for the stairs; that's my main problem. Her nails were just trimmed and she still has problems. What should I do?

- Why can't you get carpet runners??

- Q: Is tiles and tiles the same?

- Floor tiles; is a ground decoration material, also known as floor tiles. Made of clay. Specifications variety. Quality Kennedy, pressure wear, can moisture. Some by glazing treatment, with decorative effect. Used for public buildings and civil buildings on the ground and floor. Tiles; is a refractory metal oxide and semi-metal oxide, through the grinding, mixing, pressing, glazing, sintering process, and the formation of a kind of acid and alkali porcelain or stone and other building or decoration materials, Collectively called tiles. The raw materials are mostly made of clay, quartz sand and so on. Differences; floor tiles are cement tiles (including slag bricks), tiles are cement tiles on the surface of the glaze - Tao Mu Ju building materials

- Q: Why is the floor arch? How to handle the arch?

- The main reason for the arching of the floor is because the concrete floor before the floor is not completely dry, resulting in the late temperature rise after the water can not evaporate and produce expansion, the treatment method is: If the room area is not large, you can ask the professional wood workers first The edge of the wall of the presser foot (kick line) line off, and then cut the saw blade to the edge of the wall saw part, and finally the skirting line can be installed.

- Q: I want to lay floating floors but my OSB sub floor is uneven. In some spaces it gets close to a inch in difference. I was wanting to know if floor leveling compound will fix this? Also if you could give my a brand or name of a good one.

- If the difference is as large as an inch I would be concerned that something is wrong, swelling or flexing. I would get under the house if possible and inspect it from there. There may be water damage and you will need to replace the subfloor. If things are just sagging, you may be able to install braces perpendicular to the floor joists to fix the problem. If it's all solid but still has the difference then you could try the floor leveler. You may need to use a belt sander to even things out. Worst case scenario you will have to have a transition from the lower part to the higher part.

Send your message to us

eco-friend wood plastic composite wall panel wpc cladding

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords