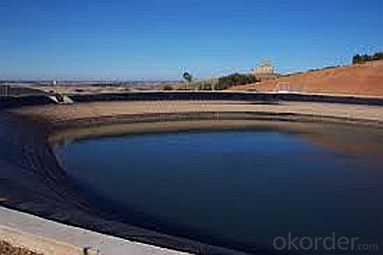

Earth Geotextile High-Density Polyvinyl Chloride (HDPE) Pond Geomembrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Geomembrane

Classified by Material

1. HDPE Geomembrane

2. LDPE Geomembrane

3. LLDPE Geomembrane

Material: HDPE, LDPE

Thickness: 1mm-3mm

Width:4m-9m

Quality Inspection Standard: GB/T17643-1998

Quality Control Measure: strictly comply with ISO9001:2000

Have passed the CE certificate in Sep. 2008.

Features:

1) Can bear chemical erosion.

2) A wider using temperature range and a longer using life.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles contribute to soil separation?

- Geotextiles contribute to soil separation by acting as a barrier between different types of soil, preventing them from mixing and maintaining their individual characteristics.

- Q: What are the specifications for geotextiles in railway projects?

- The specifications for geotextiles in railway projects typically include factors such as the tensile strength, puncture resistance, elongation properties, and durability of the material. The geotextile should also have the ability to separate and stabilize the soil layers, provide filtration to prevent soil fines from clogging drainage systems, and possess adequate permeability to allow for efficient water drainage. Additionally, geotextiles used in railway projects must meet certain standards for dimensional stability and resistance to environmental factors such as UV radiation and chemical degradation.

- Q: What are the specifications for geotextiles used in geosynthetic tubes?

- Geotextiles used in geosynthetic tubes typically have specific specifications that vary depending on the specific application and project requirements. These specifications may include factors such as tensile strength, puncture resistance, permeability, UV resistance, and fabric weight. The specific specifications for geotextiles used in geosynthetic tubes should be determined based on the intended use and the engineering design of the project.

- Q: Characteristics of nonwoven geotextiles

- Non-woven geotextile has many advantages: 1) air permeability 2) filterability 3) insulation 4) water absorption 5) waterproof 6) stretch 7) not disheveled 8) feel good, soft 9) light 10) Can be restored 11) without the direction of the fabric 12) compared with the textile production of high productivity, production speed 13) low prices, can be mass production and so on. Disadvantages are: 1) Compared with the textile fabric strength and durability is poor; 2) can not be washed as other fabrics; 3) fiber arranged in a certain direction, so easy to split from the right angle and so on. Therefore, the improvement of the production method has been mainly focused on preventing the improvement of the division.

- Q: Can geotextiles be used in wastewater treatment applications?

- Yes, geotextiles can be used in wastewater treatment applications. They are commonly used in filtration systems to separate solids from liquids and provide support for various treatment processes. Geotextiles can enhance the efficiency of wastewater treatment by improving filtration, reducing clogging, and increasing overall system performance.

- Q: Are geotextiles suitable for use in landfill caps?

- Yes, geotextiles are suitable for use in landfill caps. They are commonly used in landfill engineering to reinforce the cap system, prevent erosion, provide stability, and enhance water drainage. Geotextiles help to reduce the infiltration of rainwater, control gas emissions, and prevent the release of contaminants from the landfill. Additionally, they can enhance the overall performance and longevity of the landfill cap by providing strength and durability.

- Q: Are geotextiles suitable for use in groundwater remediation systems?

- Yes, geotextiles are suitable for use in groundwater remediation systems. Geotextiles are permeable fabrics designed to separate, filter, reinforce, or drain soils, making them an effective solution for groundwater remediation. They can be used to create barriers, filter contaminants, and facilitate water flow, helping to improve the overall efficiency and effectiveness of groundwater remediation systems.

- Q: What are the different geotextile installation techniques in filtration?

- Some of the different geotextile installation techniques in filtration include direct placement, trench installation, and wrapping. Direct placement involves placing the geotextile directly on the soil surface, while trench installation involves burying the geotextile in a trench or cut. Wrapping technique involves wrapping the geotextile around a structure or pipe to provide filtration. These techniques are used to enhance filtration and prevent soil erosion in various construction and environmental projects.

- Q: Do you want to put the geotextile and the impounded vegetables in the soil?

- No, I am specializing in the production of geotextile materials

Send your message to us

Earth Geotextile High-Density Polyvinyl Chloride (HDPE) Pond Geomembrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords