Fiberglass Fabrics - e-glass stitich combo mat- tlx top quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

E-glass stitched combo mat consists of two or more layers of fiberglass roving which are stitch-bonded.One layer of rovings and different layers of roving can be oriented differently and have different liner density.The roving specification,number of roving layers,mat width and roll diameter can be customized as per requirement.

Application:

The product is most widely used in hand lay-up process and also can be used in filament winding. compression molding and continuous laminating processes. The typical end products including various panels, boats,bath equipment automotive parts and cooling towers

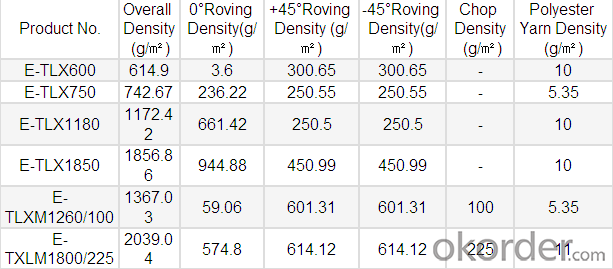

Specifications:

Packaging:

It’s wound into a paper tube( inside diameter about 90mm, outside diameter about 265mm).the mat roll is wrapped with plastic film,and then packed into cardboard box or wrapped with paper.the rolls can be stacked horizontally.the rolls can be palletized or loaded into container.

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: What are the different colors available for fiberglass fabric rolls?

- Fiberglass fabric rolls are available in a variety of colors to suit different needs and preferences. Some of the commonly available colors include white, black, gray, yellow, green, blue, and red. These colors are achieved through the use of dyes or pigments during the manufacturing process. The choice of color for a fiberglass fabric roll depends on various factors such as the intended application, aesthetic requirements, and visibility needs. For example, white or light-colored fiberglass fabric rolls are often used in applications where visibility or reflectivity is important, such as in safety clothing or high-visibility signage. On the other hand, darker colors like black or gray may be preferred for applications where aesthetics or light absorption are important, such as in theater backdrops or acoustic panels. Overall, the availability of different colors for fiberglass fabric rolls allows for customization and versatility in various industries and applications.

- Q: Can fiberglass fabrics be used for insulation in cryogenic applications?

- Yes, fiberglass fabrics can be used for insulation in cryogenic applications. Fiberglass has excellent thermal properties and can effectively insulate against low temperatures typically found in cryogenic environments. It provides a high level of thermal resistance, preventing heat transfer and maintaining the desired temperature. Additionally, fiberglass fabrics are lightweight, durable, and resistant to moisture and chemicals, making them suitable for cryogenic insulation.

- Q: Can fiberglass fabric be used for fire protection?

- Yes, fiberglass fabric can be used for fire protection. It has excellent fire-resistant properties and is often used in various industries, such as construction and manufacturing, to provide thermal insulation and prevent the spread of flames.

- Q: What are the different fiberglass fabric weaves for fire resistance?

- There are several different fiberglass fabric weaves that are specifically designed for fire resistance. These weaves are constructed in a way that enhances the fabric's ability to withstand high temperatures and prevent the spread of fire. Some of the commonly used fiberglass fabric weaves for fire resistance include: 1. Satin Weave: Satin weave fiberglass fabric is characterized by a tight, closely woven pattern that provides excellent strength and fire resistance. The weave consists of multiple warp yarns floating over several weft yarns, allowing for a dense and durable fabric. 2. Twill Weave: Twill weave fiberglass fabric is known for its diagonal pattern, created by the staggered interlacing of warp and weft yarns. This weave offers good flexibility and thermal resistance, making it suitable for applications requiring fire protection. 3. Plain Weave: Plain weave fiberglass fabric is the simplest and most common weave. It features a simple over-under interlacing of warp and weft yarns, creating a balanced and uniform fabric. Although not as strong as satin or twill weaves, plain weave fabric still offers decent fire resistance. 4. Basket Weave: Basket weave fiberglass fabric is characterized by a distinctive crisscross pattern, created by multiple warp and weft yarns weaving over and under each other in a regular sequence. This weave provides a robust and fire-resistant fabric, often used in high-temperature applications. 5. Leno Weave: Leno weave fiberglass fabric is made by crossing warp yarns over weft yarns in pairs, creating an open, grid-like structure. This weave offers good breathability and fire resistance, making it suitable for industrial applications where ventilation and heat resistance are essential. It's important to note that the choice of fiberglass fabric weave for fire resistance depends on the specific requirements of the application. Different weaves have varying levels of strength, flexibility, and fire resistance, so it's crucial to select the most appropriate weave based on the intended use and desired level of fire protection.

- Q: How does fiberglass fabric perform in high-altitude environments?

- Fiberglass fabric performs well in high-altitude environments due to its excellent strength-to-weight ratio and resistance to extreme temperatures. It can withstand the harsh conditions and maintain its integrity, making it suitable for various applications such as aerospace components and protective gear for mountaineers.

- Q: Is fiberglass fabric resistant to chemicals in industrial settings?

- In industrial settings, fiberglass fabric is generally resistant to chemicals. This fabric is made from fine glass fibers, which give it excellent resistance to a wide range of chemicals, including acids, alkalis, solvents, and oils. As a result, it is suitable for use in industries where workers come into contact with various chemicals, such as chemical processing, petrochemical, and pharmaceutical industries. Additionally, fiberglass fabric is well-known for its ability to withstand high temperatures and its flame retardant properties, making it even more suitable for industrial environments. However, it is important to note that the resistance of fiberglass fabric to chemicals may vary depending on the specific type and concentration of the chemical. Therefore, it is always recommended to consult the manufacturer's specifications or conduct compatibility tests before using fiberglass fabric in a particular industrial application.

- Q: How does fiberglass fabric perform in electrical conductivity?

- Fiberglass fabric is known for its excellent electrical insulation properties, making it a poor conductor of electricity. This is because fiberglass is made up of fine glass fibers that are non-conductive and do not allow the flow of electrical current. As a result, fiberglass fabric is commonly used in electrical insulation applications to prevent the risk of electrical shocks or short circuits. Additionally, fiberglass fabric is also resistant to high temperatures, chemicals, and UV radiation, which further enhances its performance as an electrical insulator. Overall, fiberglass fabric is a reliable material when it comes to electrical conductivity, offering excellent insulation properties for a wide range of applications.

- Q: Is fiberglass fabric suitable for use in aerospace interiors?

- Yes, fiberglass fabric is suitable for use in aerospace interiors. It is lightweight, strong, fire-resistant, and offers excellent insulation properties. Additionally, it is durable and has low maintenance requirements, making it an ideal choice for various applications in the aerospace industry.

- Q: With what glue can stick glass steel cans?

- The modified epoxy adhesive can stick to the FRP tank;In addition to the epoxy resin and other non-polar polyolefin plastic adhesive is not good, for all kinds of metal materials such as aluminum, steel, iron, copper; non metallic materials such as glass, wood and concrete; and thermosetting plastics such as phenolic, amino, unsaturated polyester has excellent adhesive properties, so it is called monengjiao. Epoxy adhesive is an important kind of structural adhesive.

- Q: Is fiberglass fabric resistant to staining or discoloration?

- Yes, fiberglass fabric is highly resistant to staining or discoloration.

Send your message to us

Fiberglass Fabrics - e-glass stitich combo mat- tlx top quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords