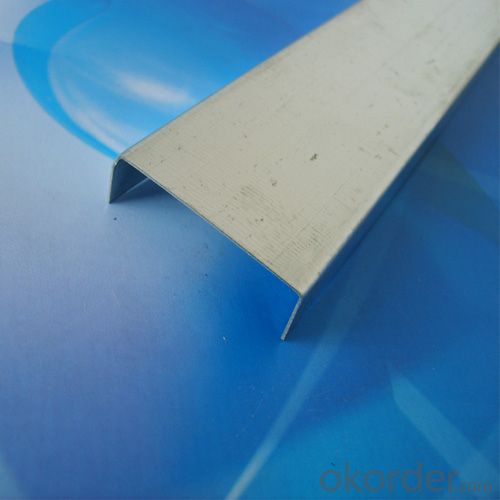

Drywall Vertical Keel in Steel Framing System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

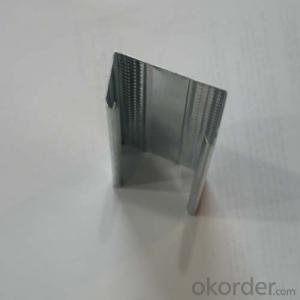

Specification(Width*Height*Gauge): (Customization Acceptable)

Product Code | Width(mm) | Length(mm) | Gauge(mm) | Height(mm) |

QC50 | 48 | customization | 0.4/0.5/0.6/0.7 | 50/45/40/35/30 |

QC60 | 58 | customization | 0.4/0.5/0.60.7 | 50/45/40/35/30 |

QC75 | 74 | customization | 0.5/0.6/0.7/0.8 | 50/45/40/35/30 |

QC90 | 89 | customization | 0.5/0.6/0.7/0.8 | 50/45/40/35/30 |

QC100 | 98 | customization | 0.5/0.6/0.7/0.8 | 50/45/40/35/30 |

Other specifications | Orders can be customized | |||

Introduction

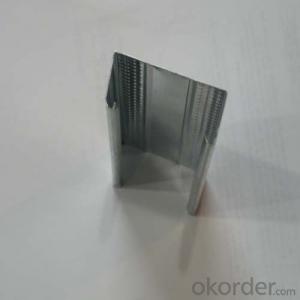

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

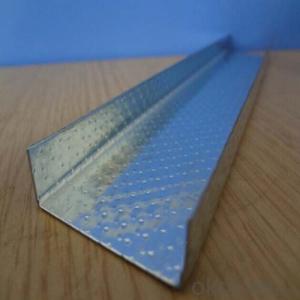

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the keels' vertical points and intensity.

(4) The metal stud with hole : one of our product is the special hole on C-stud every 600mm, which is easy for workers to install the electric lines and water tubes.

(5) Various sizes of metal track and metal stud : we are able to manufacture German, Japan and Aus-American types etc..We can meet your customized demands.

(6) Factory direct sale price : We have our own factory to produce raw materials----galvanized(zinc coated) steel, as well as the product line, so we can provide you a lowest price.

Drywall section metal profile

1. Usage: gypsum board drywall

2.Easy to install

3.High strength

4.Size exact, easy cut

Metal steel profile stud and track light steel keel for drywall system

Product Show

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: Who used the light steel keel gypsum board to do the wall?

- Not compare province, province, then you buy bricks more province, just better installed than brick light

- Q: 6 meters high ceiling to do 4 meters with light steel keel do wall light steel dragon skeleton is to do 6 meters to the top or do high

- Formal practice, must be done to the top, unless it is not the request, nobody tube project, it may not be the top.

- Q: Home improvement in the partition

- Light steel keel, wood keel wall: light steel keel is a substitute for wood keel products, fire effect is significant (when using wood keel to brush fire retardant coating). As a partition wall of the external use of the plate there are gypsum board, Ed panels and aluminum-plastic panels, according to the actual requirements. If you want to do noise effects, in the middle of the installation of rock wool or mineral wool sound-absorbing panels;

- Q: House decoration, the designer said the wall with light steel keel good, but the construction told me that this low efficiency can only be maintained for 4,5 years so I do not know in the end listen to who

- Mainly to see the use of the environment, if used in a humid environment, the life must be short, so the bathroom wall is best not to use light steel keel search.

- Q: Gypsum board wall above the good paint glass?

- Gypsum board partition wall construction operation process: (1) According to the design drawings, in the already done walls, floors, the ground release off the line, the door hole edge. (2) according to the design drawings and the actual size, with a wheel cutting machine cutting keel and classified stacking. (3) according to the line has been put away and the door edge, with nails or expansion bolts to the ground keel fixed on the ground floor, nail or expansion bolt spacing 600mm. The top of the keel into the wall of the reserved hole 100mm, and then use cement mortar packing fixed, or with nails, expansion bolts to the end of the handle along the top keel fixed to the wall. (4) According to the cut line and the edge of the door, according to the size of the file size layout, painted in the edge, along the top keel, less than the modulus should be placed in the partition with the wall at the first board. (5) According to the document mark will be cut in advance of the length of the vertical keel in turn inserted along the edge, along the top keel groove, the flange towards the direction of the proposed panel to be installed. Adjust the vertical, positioning accuracy, with rivets fixed. The vertical keel on the wall is fixed to the wall with a nail or expansion bolt, and the distance between the nail or the expansion bolt is 1m. (6) the installation of doors and windows to strengthen the installation of the keel: the first installation of the hole on both sides of the vertical reinforcement keel, and then install the hole up and down to strengthen the keel, and finally install the big hole on both sides of the upper and lower reinforcement keel and bracing. (7) Install the cross brace and support card. The vertical keel fastened, so that the entire partition keel has sufficient strength and stiffness.

- Q: PVC plastic buckle the corners of the corner is how fixed to the wall of the buckle is how and cords connected to the light steel keel and gypsum do cut off the light steel keel is how and the wall surface and ceiling how fixed

- Read it down tired ah, this thing is very simple, buy materials, when the ingredients will be equipped with, you think about it, so many carpentry is not very smart how to install it so simple, it is the factory has been thought All the accessories are very complete.

- Q: Waterproof gypsum board for toilet partition and paste tile installation steps?

- The exterior wall of the bathroom is made of ordinary type gypsum board (size 1.2M * 3.0M). Can be fixed with pneumatic nails, can also be used 4 * 20 anti-rust self-tapping screws.

- Q: Use light steel keel to do the shelf, install the glass partition wall, this process is feasible? How about construction?

- It is quite possible that this practice is very common. In the office building decoration, it will often use this method to do with the installation of glass. Just, light steel keel need to use gypsum board to do the surface closed, and with latex paint in the final decoration.

- Q: Will the light steel keel, brick block, light partition wall do inside the wall what are the advantages. Including the price, as much as possible, thank you!

- Light steel keel light steel keel easy to install, suitable for office, plant and so on.

- Q: What is the difference between gypsum board partitions and lightweight partitions?

- Gypsum board wall, refers to the surface with gypsum board to do the closed wall, it is also a "light partition" of a. Lightweight partition, which includes gypsum board partition, cement board partition, light block brick wall and so on.

Send your message to us

Drywall Vertical Keel in Steel Framing System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords