Drywall Vertical Keel In Steel Framing System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification(Width*Height*Gauge): (Customization Acceptable)

Product Code | Width(mm) | Length(mm) | Gauge(mm) | Height(mm) |

QC50 | 48 | customization | 0.4/0.5/0.6/0.7 | 50/45/40/35/30 |

QC60 | 58 | customization | 0.4/0.5/0.60.7 | 50/45/40/35/30 |

QC75 | 74 | customization | 0.5/0.6/0.7/0.8 | 50/45/40/35/30 |

QC90 | 89 | customization | 0.5/0.6/0.7/0.8 | 50/45/40/35/30 |

QC100 | 98 | customization | 0.5/0.6/0.7/0.8 | 50/45/40/35/30 |

Other specifications | Orders can be customized | |||

2. Specification

commodity | size (mm) | thickness (mm) | length (mm) | pack |

Australia system | ||||

Primary cross rail | 25*21 | 0.55, 0.75,0.85,1.0 | 3600, 4800 | 10 |

Furring channel | 28*38 | 0.55, 0.75,0.85,1.0 | 3000,3600,4800 | 25 |

Wall track | 26*16*26 | 0.45,0.55,0.75 | 3000 | 20 |

Angle | 30*30 | 0.55, 0.75 | 3000 | 50 |

Stud | 51*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 |

64*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 | |

76*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 | |

92*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 | |

Track | 51*32/50 | 0.55, 0.75 | 3000 | 10 |

64*32/50 | 0.55, 0.75 | 3000 | 10 | |

76*32/50 | 0.55, 0.75 | 3000 | 10 | |

92*32/50 | 0.55, 0.75 | 3000 | 10 | |

Middle East system | ||||

Main channel | 38*12 | 0.45,0.50,0.60,0.80,1.0 | 2400,2950,3600 | 20 |

Furring channel | 68*35*12 | 0.40,0.45,0.50,0.60 | 2400,2950,3600 | 25 |

Edge channel | 25*25 | 0.35,0.40,0.45,0.50 | 3000 | 50 |

Stud | 50*34.5 | 0.40,0.45,0.50 | 3000,3600,4800 | 10 |

70*34.5 | 0.45,0.50,0.60 | 3000,3600,4800 | 10 | |

75*34.5 | 0.45,0.50,0.60,0.70 | 3000,3600,4800 | 10 | |

100*35 | 0.50,0.60,0.70,0.80,1.0 | 3000,3600,4800 | 10 | |

Track | 52*25 | 0.40,0.45,0.50 | 3000,3600,4800 | 10 |

72*25 | 0.45,0.50,0.60 | 3000,3600,4800 | 10 | |

76*25 | 0.45,0.50,0.60,0.70 | 3000,3600,4800 | 10 | |

100*25 | 0.50,0.60,0.70,0.80,1.0 | 3000,3600,4800 | 10 | |

East Europe system | ||||

CD | 60*27 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 12 |

UD | 28*27 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 20 |

T-type keel | 20*6 | 0.35,0.40,0.45 | 2400,3000,3600 | 50 |

24*10 | 0.35,0.40,0.45 | 2400,3000,3600 | 50 | |

Stud (CW) | 50*50 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 |

70*50 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

75*50 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

100*50 | 0.40,0.45,0.50,0.60,0.80,1.0 | 2800,3000,3600 | 10 | |

Track (UW) | 52*40 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 |

72*40 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

75*40 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

100*40 | 0.40,0.45,0.50,0.60,0.80,1.0 | 2800,3000,3600 | 10 | |

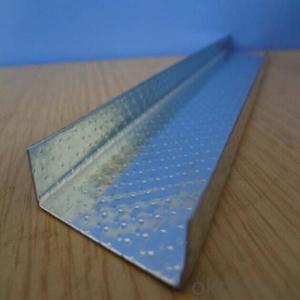

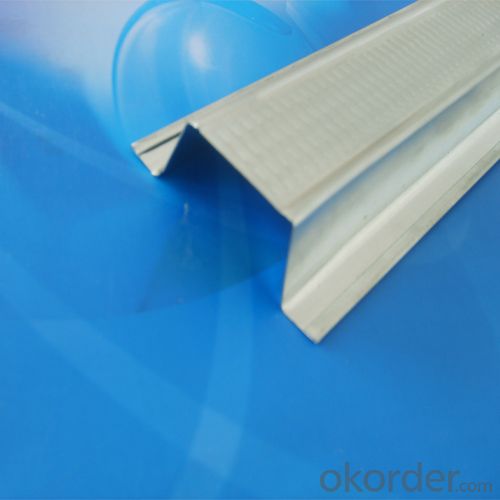

Drywall section metal profile

1. Usage: gypsum board drywall

2.Easy to install

3.High strength

4.Size exact, easy cut

Product Overviews

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q:Light steel keel wall how to calculate

- Light steel keel is a new type of building materials, with the development of China's modernization, in recent years has been widely used in hotels, terminals, passenger stations, stations, theaters, shopping malls, factories, office buildings, Interior decoration, ceiling and other places. Light steel keel wall with light weight, high strength, good fire resistance, versatility and easy installation characteristics, to adapt to shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, Easy to deformation and so on. Process: In order to avoid the root wall vulnerable to moisture, deformation, mildew and other quality problems, the bottom of the partition to be made pillow base;

- Q:What kind of new material is now called a "light partition" in the house? Is it safe?

- Light steel keel inorganic composite board partition is a high toughness material, compared to the traditional partition, better shock resistance. In the simulation of super 8 earthquake experiment, the traditional block wall has long been decomposed collapse, but the light steel keel inorganic composite board wall is still solid and reliable, showing its seismic capacity far more than the traditional wall, which is light steel Keel inorganic composite board partition in Japan widely used reasons, security is the primary consideration of residential construction factors.

- Q:What are the consequences of installing a hanging cabinet on gypsum board wall?

- Gypsum board can not load, do not install gypsum board door hanging cabinet. If the impact of drilling position is keel, then the impact of the impact of drilling, will issue a big voice, and the whole wall has a shock; if the keel is light steel keel, it will soon penetrate, But it is possible to make the fixed gypsum board screws off, causing the gypsum board loose; if it is wood keel, the impact drill can play wood slag to.

- Q:Light steel keel wall in the end is how much money to know

- Generally do light steel keel gypsum board wall package package material about 100 yuan a square meters. Mainly to see the price of materials, the general dragon licensing gypsum board and light steel keel more expensive.

- Q:Decorative light steel keel paper gypsum board wall height of 4.1 meters span 6.5 meters need not add structural column, beam

- Do not understand what the title of the 'span' is a special term, the wall is a vertical component, there is no 'span'

- Q:Gypsum board wall above the good paint glass?

- Gypsum board partition wall construction operation process: (1) According to the design drawings, in the already done walls, floors, the ground release off the line, the door hole edge. (2) according to the design drawings and the actual size, with a wheel cutting machine cutting keel and classified stacking. (3) according to the line has been put away and the door edge, with nails or expansion bolts to the ground keel fixed on the ground floor, nail or expansion bolt spacing 600mm. The top of the keel into the wall of the reserved hole 100mm, and then use cement mortar packing fixed, or with nails, expansion bolts to the end of the handle along the top keel fixed to the wall. (4) According to the cut line and the edge of the door, according to the size of the file size layout, painted in the edge, along the top keel, less than the modulus should be placed in the partition with the wall at the first board. (5) According to the document mark will be cut in advance of the length of the vertical keel in turn inserted along the edge, along the top keel groove, the flange towards the direction of the proposed panel to be installed. Adjust the vertical, positioning accuracy, with rivets fixed. The vertical keel on the wall is fixed to the wall with a nail or expansion bolt, and the distance between the nail or the expansion bolt is 1m. (6) the installation of doors and windows to strengthen the installation of the keel: the first installation of the hole on both sides of the vertical reinforcement keel, and then install the hole up and down to strengthen the keel, and finally install the big hole on both sides of the upper and lower reinforcement keel and bracing. (7) Install the cross brace and support card. The vertical keel fastened, so that the entire partition keel has sufficient strength and stiffness.

- Q:Will the light steel keel, brick block, light partition wall do inside the wall what are the advantages. Including the price, as much as possible, thank you!

- Light steel keel life in humid environment Short brick block from the weight of large but because the single volume of small transport more convenient light partition board can be used for humid environment but a single volume upstairs is not convenient to install as light steel keel convenience The cost gap is not big

- Q:Light steel keel wall how to install glass door

- And the normal installation of the same glass doors, but to consider the load-bearing, door frame to be reinforced, upstairs that useful wood panels are also available. However, we usually use the side tube to do support.

- Q:Light steel keel wall waterproof

- 1. The use of steel coated excellent 1011 metal roof for high-elastic waterproof coating (grass-roots) Used for bonding with the substrate, to achieve 100% continuous sticky. 2. Use 1032 to enhance the polyester cloth Used to enhance the coating of tensile, tear resistance and fatigue resistance. 3. The use of steel coated excellent 1011 metal roof for high-elastic waterproof coating (grass-roots) By enhancing the gap of the mesh structure of the polyester cloth, the intermediate layer and the base coating are fully infiltrated and integrated to effectively enhance the sealing performance of the coating. 4. Use steel coated excellent 1021 metal roof dedicated high-elastic waterproof coating (surface)

- Q:Wood keel can be used to ceiling, can be used to do the wall? Light steel keel can be used in what place?

- Wood keel is best used, one is poor fire, the second is easy to produce pests, and now the ceiling are gradually replaced by light steel keel keel.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Drywall Vertical Keel In Steel Framing System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords