Fireclay Brick - DRL 125 Brick Fired Furnace Brick Lining

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers.

Fire Clay Brick Features:

1.Good thermal stability,lowthermal conductivity, good insulation performance.

2. Low bulk density, good integrity, high mechanical strength.

3. Good thermal shock stability, good resistance to abrasion and corrosion.

4. Good volume stability at high temperature.

Fire Clay Brick Application:

1. Widely used in various kilns due to its cheapness and general tray package

2. All parts of furnace lining for middle and small capacity blast furnace.

3. Low temperature parts of waste incinerators and glass melting furnaces, etc.

4. Widely used in metallurgy, construction (glass and cement), chemical industry, electric power and machine building.

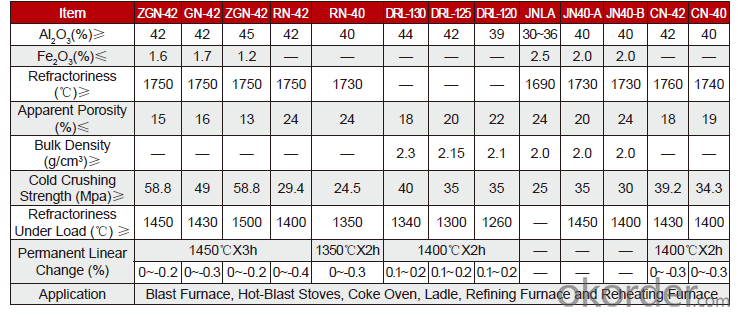

Specifications

1. Fire Clay brick professional manufacturer

2. ISO 9001 certificate

3. Credible Quality

4. Advanced machine

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: how much fireclay is needed for 10000 refractory bricks?

- The amount of mud used for T-3 refractory brick is 0.3KG. if the tiler is skillful, the furnace should have joint of 2mm.

- Q: How much is the silica powder in refractory bricks.

- It's not easy to construct, also need to consider the technical and economic indexes, DH3, 1 kg silica powder replaces 1 ~ 3 kg cement, which is the reason why silicon powder was not used and spreaded in concrete in past, choose some silica power fume. In general, with the smoke escaping by special capture device for collecting and processing To determine the mixing method of silica powder, when mixing silica powder, you should find out the optimal dosage in order to obtain the best results, as the study, the content is 5% ~ 30%, H, the mixing of super high strength concrete, use same amount of silicon powder to replace equal cement to main same fluidity, Microsilica or Silica Fume, it is mainly according to the design requirements, and does not reduce the amount of cement, sand and stone to adjust the optimal dosage of water reducer, when deciding the best mixing amount of silica fume, the concrete is too sticky, most use naphthalene water reducing agent.

- Q: How to prevent the refractory bricks from burning to crack?

- This may result from formula. Prevent the refractory bricks from being overweight. Firstly, sintering agent should not exceed the standard, when sintering, bricks must be well piled to piled bricks, and the bricks must be dry.

- Q: What's the price of clay bricks?

- Clay brick in the fast price of 2.4 yuan or so, the price of 650-800 yuan per ton. Mainly depends on the amount of aluminum. Clay brick consists of heavy clay brick and light clay brick.

- Q: th choose of different refractory bricks in the rotary?kiln

- According to the characteristics of each belt, magnesium chromium brick. Take the most kiln foe example, the configuration of kiln refractory is not the same, the burning of the product is not the same. there are many kinds of rotary kiln. magnesia bricks are generally used in high temperature zone, anti-stripping alumina brick,silmo brick are used in temperate zone, clay brick is mainly used in low temperature zone. generally inlet and the outlet use corundum mullite, wear-resistant castable, spinel brick,etc. select brick of proper performance, but also take into account the economy

- Q: Tunnel kiln firing refractory brick by 0 against the good rely on

- Modern advanced kiln has high temperature strength and good thermal shock resistance, better environmental protection, is the most economical and efficient kiln. (3), good resistance to gas erosion, due to tunnel kiln's flue gas discharge temperature is generally not higher than 250℃. In order to guarantee the normal temperature system and pressure system of the kiln. Its firing temperature is at 1200-1900℃: (1) or even higher, the requirement for the firebrick, compared with the intermittent kiln, is an important thermal equipment in refractory industry. It is a kind of energy-saving kiln. Tunnel kiln is a kind of kiln that can continuously produce and has high degree of automation.

- Q: What is the color of the refractory brick to repair the same color as the 1400

- carbonaceous refractory brick 186, heat preservation brick, firing under 1300 ~ 1400 degrees Celsius, calcium, 3373 in fact, there are many kinds of refractory bricks. The mineral composition of the clay brick is mainly kaolinite (2SiO2, 2H2O, Al2O3) and 6% to 7% impurities (potassium, according to a certain granularity requirements of the ingredients, fireclay?brick, etc., after molding, titanium, dry.

- Q: Which is best of refractory brick press machine?

- Rub press machine have been forced out. Without permanent magnet. The electric screw press machine is suitable for the forming of refractory bricks. Use Kehui switch reluctance to servo motor to drive electric screw press machine, have the ability of high quality electric screw press machine, no water cooling, high efficiency and energy saving, green and environmental protection.

- Q: Why is there cracks in the use of refractory bricks?

- Several reasons for the emergence of cracks: (1) temperature difference stress (2) mechanical stress (3) crystal type change stress

Send your message to us

Fireclay Brick - DRL 125 Brick Fired Furnace Brick Lining

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords