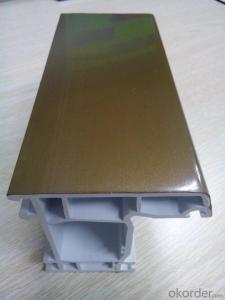

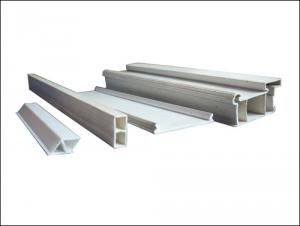

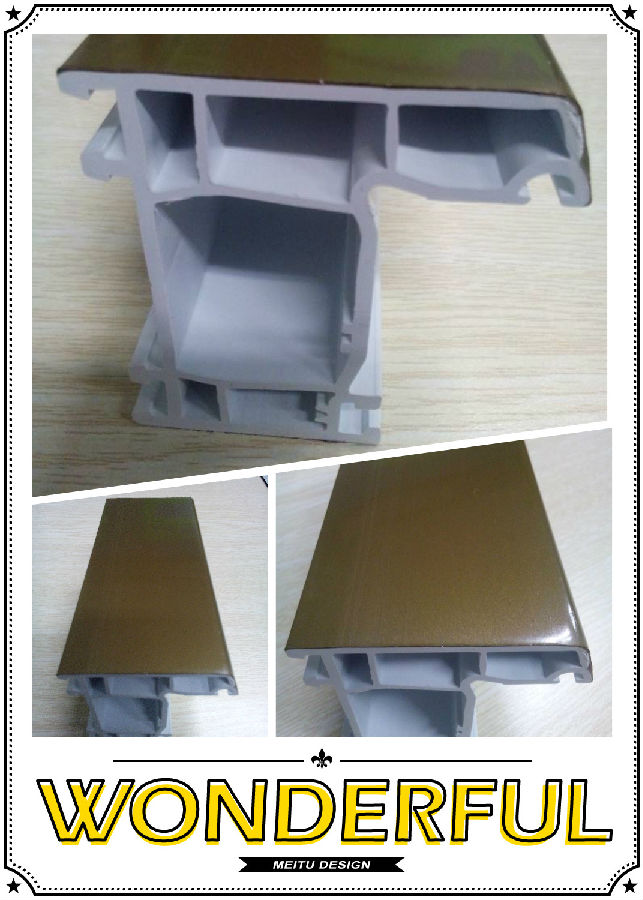

Double color coextrusion profile for window frame

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

European Double color coextrusion profile for window frame

1. Quick details

Type: PVC window profile | Place of Origin: Liaoning, China (Mainland) | Model Number: ZW60-01 |

Basic deptah: 60mm | Used for:fixed window ,single,double casement window,muntin and others fenestrato | Applicable glass sizes:20mm |

Weight: 1.00Kg/m | Package: 6 pcs/bundle | Length: 6m |

MOQ: 5 Tons | Colour:Champagne | Chamber:4 |

Opening type: casement | Monthly Output: 300 Tons | Trade Term : EXW,FOB,CIF Delivery: 15-25 Days After Receive You Deposit |

Payment Term :T/T,L/C | Production Lead Time: Usually 10-15days | Delivery : 15-25 Days After Receiving 30% Deposit of T/T or L/C |

2. Specifications

Its characteristics are corrosion tension proof, undeformed, resisting , easy cleaning, aging resisting , breath freely and translucidus

3. Packaging & Delivery

Packaging Details:

1)Packing in plastic bags and then as your requirement. 2)6m/piece length or customizable.

Loading: 20'GP about 10 tons

40'GP about 20 tons

40'HQ about 23 tons

Sample shipping. Sent out orders in 24 hours by TNT, DHL, EMS FedEx etc.

By air (DHL, FedEx, UPS, etc.)

By sea shipping when bulk order

A). Sample's lead time:1-2 days

B). 20'GP lead time: 5-8 days

40'GP lead time: 8-15 days

40'HQ lead time:10-15 days

- Q: What is the quality of plastic steel profiles in the end?

- Quality in general, market acceptance can be, but the price is relatively high.

- Q: The difference between steel and aluminum alloy profiles

- Plastic windows are easy to weather, aluminum alloy will not. If you want to be insulated when you do windows with double glass

- Q: How plastic embossed profiles are made

- Plastic processing is a complex process, generally divided into the following main processing methods:

- Q: Specification for steel profiles

- Before 50, did not use 40 or 38, 10 years ago I have done spliced steel, and now who is willing to splicing ah. But really want to splice, and now have steel can also be spliced.

- Q: Plastic profile brittle extrusion process unreasonable reasons

- Excessive or insufficient material This is related to the process temperature setting and feeding ratio. The temperature setting is too high to cause the material to be plasticized. Some of the components with low molecular weight in the component will decompose and evaporate. The temperature is too low. Fully welded, the molecular structure is not strong, while the feed ratio is too large cause the material heating area and shear increases, the pressure increases, easily lead to plastic; feeding ratio is too small material heating area and shear reduction, Resulting in less plasticized, whether it is plastic or plastic surgery will cause plastic profiles crisp cutting collapse phenomenon.

- Q: Plastic steel window profile specifications models which

- Plastic doors and windows are made of polyvinyl chloride (PolyVinyl Chloride, often referred to as PVC) resin as the main raw material, plus a certain percentage of stabilizers, colorants, fillers, UV absorbers, etc., by extrusion molding, and then Through the cutting, welding or screw way made of doors and windows frame fan, equipped with sealing tape, tops, hardware, etc., at the same time to enhance the rigidity of the profile, more than a certain length of the cavity needs to fill the steel lining Tendons), so made of portal windows, called steel doors and windows.

- Q: What is the steel profile?

- Simply put the profile is installed into a window that can still be seen after the outer surface. Such as the large and small faces of the box. While the middle glass trough installed glass and pressed after the invisible, that is non-visible surface.

- Q: What belongs to plastic profiles

- Plastic profile additives four: processing aids Auxiliaries are mainly developed to improve the performance of plastic molding. Plastic profile processing temperature and decomposition temperature is close, poor mobility, easy to stick in the equipment on the coking, so the production of plastic profiles need to add a certain amount of processing aids to overcome the defects of plastic profiles themselves. Plastic profile additive five: light stabilizer The light stabilizer can inhibit the photooxidation degradation reaction of the polymer by shielding and absorbing ultraviolet rays, quenching and exciting energy to capture free radicals, so as to give the products a good light stabilizing effect and prolong their service life. Plastic profile additives six: filler The filler is a solid additive that is different in composition and structure from plastic, also known as fillers. To improve the physical and mechanical properties of plastic and reduce the cost of plastic has a significant effect and economic value. Plastic profile production formula to add filler, plastic profiles can be heated after the size of the change in the rate of change, increased impact strength, increased rigidity, while also reducing production costs.

- Q: What is the broken bridge of aluminum? What are the characteristics?

- Waterproof, fireproof, anti-theft performance: broken bridge aluminum doors and windows with a rainwater structure designed to completely separate the rain from the outdoor, watertight in line with national standards; its aluminum alloy material for the metal material, Can be a good solution to the family fire hazard; for anti-theft performance is good, because the broken bridge aluminum composite window prepared a good hardware accessories and senior decorative locks, thieves face it can only helpless.

- Q: PVC extrusion profiles compared to ABS, PE and other plastic profiles have any advantages?

- ABS weather resistance is poor, the proportion of light, chemical resistance is poor, but if the ABS and PVC blending modified into PVC / ABS alloy pellets, you can combine the advantages of two products in one, the price is cheap, the current price 14500-17000 yuan / ton.

Send your message to us

Double color coextrusion profile for window frame

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches