Sintering machine desulfurization dust removing tower

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel sintering machine desulfurization dust removing tower

Our company specializing in the production of glass steel desulfurization tower, the waste heat of the flue gas desulfurization tower, power plant desulfurization tower, steel desulfurization tower, environmentally friendly desulfurization tower, double alkali method desulfurization tower, water film desulfurization tower, industrial furnace desulfurization tower, sintering furnace desulfurization tower, boiler flue gas desulfurization tower, desulfurizing tower and other environmental protection equipment in Colleges and universities. Welcome the masses of friends to buy!

Steel sintering machine desulfurization and dedusting tower adopts the principle of design and the special manufacturing process, so that the gravity settling, inertia deposition, adsorption, surface force, no plug nozzle jet, dust removal and desulfurization mechanism of acoustic wave and the special structure of the atomization, a multi-channel, desulfurization reaction, and special dehydration demister, the sintering machine desulfurization dust removing tower dust removal efficiency of iron and steel plant high, well repair operation, low cost, stable performance, simple operation. Sintering machine desulfurization dust removing tower special high temperature resistance, wear resistance, corrosion resistance, long service life, fan operation without water. Special opponent burning furnace, boiling furnace, pulverized coal boiler, the unique management effect. So steel sintering machine desulfurization dust removing tower of our company put on the market by the user and the environmental protection departments of praise.

When the draft fan is started, the dust catcher in the air discharged rapidly, at the same time the dust laden gas into the interior of the influence of atmospheric pressure and the flue gas, and reflect the spray washing spray device in the flue gas is fully mixed with water, fine dust particle cohesion and coarse aggregate, in the guide, the high-speed airflow into the barrel of the liquid, thereby to produce a large amount of foam, forming a water film, the dust of flue gas in the water has enough time to capture interactions of dust particles in the flue gas. SO2 in flue gas with strong hydrophilicity, absorption of dust removal and desulfurization effect in alkaline solution. Flue gas purification separation device after removal of water, from the chimney into the air. Sewage can be discharged into the boiler slag removing machine or into the circulating pool, sedimentation, sludge from the addition of discharge slag machine out.

Steel sintering machine desulfurization dust removing tower

Steel sintering machine desulfurization and dedusting tower adopts the principle of design and the special manufacturing process, so that the gravity sedimentation, the inertial deposition, adsorption, surface forces, no plug nozzle jet, dust removal and desulfurization mechanism of acoustic wave and the special structure of the atomization, a multi-channel, desulfurization reaction, and special dehydration demister, the sintering machine desulfurization and dedusting tower steel plant dust removal efficiency is high, operation, low maintenance cost, stable performance, simple operation. Sintering machine desulfurization dust removing tower special high temperature resistance, wear resistance, corrosion resistance, long service life, fan operation without water. Special opponent burning furnace, boiling furnace, pulverized coal boiler, the unique management effect. So steel sintering machine desulfurization dust removing tower of our company put on the market by the user and the environmental protection departments of praise.

When the draft fan is started, the dust catcher in the air discharged rapidly, at the same time the dust laden gas into the interior of the influence of atmospheric pressure and the flue gas, and reflect the spray washing spray device in the flue gas is fully mixed with water, fine dust particle cohesion and coarse aggregate, in the guide, the high-speed airflow into the barrel of the liquid, thereby to produce a large amount of foam, forming a water film, the dust of flue gas in the water has enough time to capture interactions of dust particles in the flue gas. SO2 in flue gas with strong hydrophilicity, absorption of dust removal and desulfurization effect in alkaline solution. Flue gas purification separation device after removal of water, from the chimney into the air. Sewage can be discharged into the boiler slag removing machine or into the circulating pool, sedimentation, sludge from the addition of discharge slag machine out.

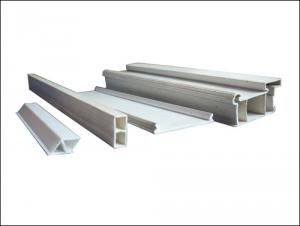

- Q: Plastic doors and windows and plastic windows do not like?

- Plastic doors and windows that use U-PVC plastic profiles made of doors and windows. Plastic doors and windows with wind, water, insulation and other good features. Plastic doors and windows are made of steel and steel profiles of doors and windows, steel profiles are made of plastic and steel profiles made of mixed.

- Q: PVC plastic profiles dip in the seam, how to deal with seamless docking

- Fill too much for the current market price of profiles is low, and the pattern of rising raw material prices, profile manufacturers are to reduce the cost of the article, the formal profile manufacturers through the optimal combination of formula is not to reduce the quality of the premise, Cost; some manufacturers are in reducing costs while also reducing the quality of products. As a result of the ingredients of the formula, the most direct and effective way is to increase the filler, in the PVC-U plastic profile commonly used filler for the calcium carbonate. Most of the previous formula system is to add heavy calcium, the purpose is to increase the rigidity and reduce costs, but the calcium particles because of their irregular shape and relatively thick particle size and PVC resin body compatibility is poor, so the number of its added Low, and the number of copies will increase the color and appearance of the impact. Now with the development of technology, most of the use of ultra-fine light activated calcium carbonate, and even nano-calcium carbonate, which not only play a role in increasing rigidity and filling, but also has the role of modification, but its filling is not Infinitely, the proportion should be controlled. Now some manufacturers in order to reduce the cost of calcium carbonate added to 20-50 copies, which greatly reduces the physical and mechanical properties of profiles, resulting in this chapter referred to the phenomenon of brittle profile.

- Q: Fence material outside the plastic inside is iron or steel this material called

- Plastic steel profiles are made of polyvinyl chloride (PVC) resin as the main raw material, plus a certain proportion of stabilizers, colorants, fillers, UV absorbers, etc., by extrusion of the profile.

- Q: China 's top ten brands of steel profiles in 2014

- Vikavica plastic doors and windows are produced by the German company of Vicat plastics in Shanghai. In the eastern coastal provinces of China occupies a considerable market. Is one of the top ten brands of steel doors and windows in China. It is a foreign - funded enterprise. It is one of the large - scale steel - making windows and doors enterprises directly under the Ministry of Construction of the new world. Companies in China's northeast Liaoning Anshan, China's steel doors and windows is one of the top ten brands.

- Q: What is the meaning of steel profiles 80?

- Plastic profiles are used for the production of doors and windows with PVC profiles, as early as the late 1950s has been in Germany, China began in 1983 from the beginning of the 20th century, the late 90s began universal application. Because simply use PVC profiles processing doors and windows strength is not enough, usually in the cavity to add steel to enhance the stability of doors and windows, so the profile of the steel interior made of plastic doors and windows are often called steel doors and windows. With the extensive use of steel doors and windows, PVC profiles for the production of steel doors and windows are commonly known as steel profiles. Plastic steel profiles are made of polyvinyl chloride (PVC) resin as the main raw material, plus a certain proportion of stabilizers, colorants, fillers, UV absorbers, etc., by extrusion of the profile.

- Q: It is good for aluminum alloy

- It is also good for aluminum alloy. The strength of the aluminum alloy is three times the strength of plastic, wind pressure strength than plastic two high. Aluminum alloy frame cross-sectional area of only steel 1/3, window frame weight is much lighter. Plastic doors and windows due to the strength of the material and low steel, although the steel lining by adding enhanced, but its wind pressure and watertight performance than the aluminum alloy window two levels. Just because the plastic window steel lining is not in its profile lap angle to connect the complete frame system, window frame, fan four corners and the T-shaped plastic angle of penetration is relatively low, so the high-rise buildings should be used with caution.

- Q: PVC extrusion profiles compared to ABS, PE and other plastic profiles have any advantages?

- PVC extrusion profiles compared to ABS, PE and other plastic profiles have any advantages? PVC is PVC, PVC in all plastics, the price is the cheapest, the advantage is cheap, toughness is better, the disadvantage is PVC Resin powder can not be used directly, but to add the relevant additives and stabilizers and auxiliary materials into, and then to produce products, the extrusion screw and barrel have special requirements. Because the plasticization of the relationship, so the equipment targeted.

- Q: What is the difference between plastic doors and windows and steel doors and windows?

- PVC plastic doors and windows in the country is widely known as the steel doors and windows, plastic doors and windows is based on polyvinyl chloride (PVC) resin as the main raw material, with a certain percentage of stabilizers, colorants, fillers, impact modifier, Absorbent (shielding agent) and other additives, the extrusion of the material.

- Q: The main features of steel profiles

- Plastic steel profile referred to as steel, the main chemical composition is PVC, it is also called PVC profiles. Is widely used as a new type of building materials, because of its physical properties such as rigidity, flexibility, corrosion resistance, excellent anti-aging properties, is usually used as copper, zinc, aluminum and other non-ferrous metals excellent substitutes.

- Q: Plastic doors and windows profiles

- The overall quality of plastic doors and windows by the quality of hardware accessories and installation of a great impact, because the domestic enterprises PVC plastic doors and windows profile profile shape and size are not the same, hardware accessories can not be unified, so the production of each variety of parts Can not be large, it is difficult to form a scale effect, in addition, due to the overall level of consumption of domestic doors and windows is still very low, limiting the price of PVC plastic doors and windows, PVC plastic doors and windows hardware accessories prices are too low, causing manufacturers to meet the market had to reduce Cost and make cheaper cheap hardware accessories. Fortunately, the new standards for plastic window hardware is being developed, hoping to standardize the hardware market. Excellent hardware accessories, can improve the overall performance of the window, such as flat window using multi-point locking than a single point of locking the sealing and wind pressure performance is much higher, the use of corner hinge or adjustable hinge its performance It is much stronger than ordinary type or saddle type hinge, it can effectively prevent fan sagging phenomenon. In addition, the use of silicified and the middle of the taps with the top of the top coat is much higher than the ordinary.

Send your message to us

Sintering machine desulfurization dust removing tower

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords