Fiberglass signs pile warning signs

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass signs is a traffic safety products, a road traffic signs, materials fiberglass, fiberglass material because no recovery value, also known as anti-theft signs. Road traffic signs warning the ban is passed instructions with text and images to drivers and pedestrians to manage road traffic safety facilities. It gives the exact road users to road traffic information to enable the smooth flow of road safety, a matter of life and property safety of drivers and pedestrians, is an indispensable traffic safety ancillary facilities.

Reflective film adhesion properties

Hand lay fiberglass materials, processes for handmade, natural cooling products, resin with hardener reaction occurs under natural conditions, often accompanied by gas production, so easy blistering after affixed reflective film, and, manual operation, because people it is often uneven wall thickness and other factors, is not suitable for mass production.

Extruded fiberglass craft. Subject to the requirements of due process, extruded fiberglass surface uneven, with pores, so lack of reflective film adhesion. Therefore, it is inappropriate to make traffic signs backplane.

Molded fiberglass. Molded fiberglass is molded under heat and pressure, surface flat, reflective film adhesion to meet the requirements. According to the Ministry of Transportation test reflective film adhesion properties for signs bottom experiment five minutes later, stripping length of reflective film is 3-4mm, significantly less than the requirements of the standard 20mm.

Strong wind load

After the hand lay-up FRP materials, the hand lay fiberglass signs on the water a month later to do stretching, bending test, the intensity decreased by 50%, since the material is not at a high temperature, high pressure molding, interior materials have bubbles, bubble water to carry out hydrolysis, the material greatly affect the strength, not for mass production.

PVC with strength aluminum panels are too low, probably in 10-20Mpa, on the coast, the wind will be able to board at the connection point to blow off.

Extruded fiberglass craft, longitudinal tensile strength is not enough.

Molded fiberglass. Molded fiberglass is molded under heat and pressure, mechanical strength, transverse and longitudinal direction force is uniform. Strength 80Mpa more

Anti-aging

FRP materials aging in the atmosphere mainly solar radiation, high temperature, humid air and the mechanical action of wind and rain, resulting in fiberglass resin surface off, exposing the white silk, weight loss, while the ultraviolet light degradation of the active substance, oxidation, fiberglass color yellowing. For the above phenomenon, must join the anti-aging agents, anti-UV agents, delay the aging process. Signage is used outdoors, when it rains, the water resistance of different resins big difference, phthalic unsaturated resin is better than vinyl unsaturated resin water resistance. Therefore, it is important for selecting the appropriate resin on the plate.

Anti-aging performance parameters and test methods specified in Table 2, the Ministry of Transportation sign resin floor.

Low cost

To save costs, reduce waste, more conducive to customer acceptance, demand for small flag shape a mold. Minimize waste.

Currently, the market triangular signs 70090011001300, 60080010001200 garden party license plate 1 m * 2 meters, the company has opened a mold can be mass-produced.

There are ribs on the back of the structure, used to enhance the overall strength of the product. And nuts embedded in the production process into products, convenience products with hoop screw connection, the product cost is lower than the aluminum plate of the same thickness, more conducive to market acceptance.

Signs board FRP technology, is an ideal and sophisticated traffic signs.

- Q: Will the model of steel profiles (such as 88-type extrusion profiles, 80 extrusion profiles) is based on what to develop ah

- The so-called 88,80,60, refers to the bottom of the profile width. The unit is millimeter. The profile manufacturers have these specifications are refers to the bottom of the width is the same, but different manufacturers of profile height is not exactly the same.

- Q: Plastic doors and windows and plastic windows do not like?

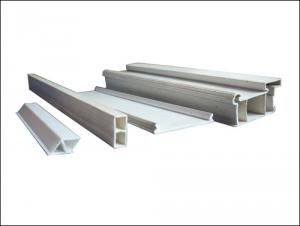

- Glass fiber reinforced plastic (FRP) doors and windows 1) abroad to alkali-free glass fiber reinforced, the product surface finish is better, no need to deal with the system can be used directly to the window. Domestic self-developed glass fiber reinforced plastic doors and windows profiles generally with alkali glass fiber reinforced, the surface of the profile after grinding, available electrostatic powder coating, surface coating and other technical processes, access to a variety of colors or texture of the decorative effect. The following are the same as the " 2) Do not use high-alkali glass fiber made of profiles. The following are the same as the " 3) FRP doors and windows profiles have a high longitudinal strength, under normal circumstances, you can not enhance the steel. But the doors and windows size is too large or high wind pressure requirements, should be based on the use of requirements to determine the enhanced approach. The transverse strength of the profile is low. Fiberglass doors and windows frame for the assembly of the turret, the joints need to use sealant seal to prevent leakage of the gap.

- Q: What is the quality of plastic steel profiles in the end?

- Quality in general, market acceptance can be, but the price is relatively high.

- Q: How many meters of a conch plastic steel profile

- Plastic specifications of a lot of steel, do not know what you want to know? But each type of material has a standard weight of rice, their own to know, for example: Conch 60 two-track sliding box weight is 1.22kg, then 1000kg divided by 1.22 = 819 meters

- Q: How plastic embossed profiles are made

- Preloading To improve the quality of the product and improve the molding efficiency, the powder or fibrous molding compound is pre-pressed into a certain shape.

- Q: Specification for steel profiles

- At present, the smallest domestic steel profile section for the 60 series, a screw-connected window called steel-plastic composite doors and windows,

- Q: Plastic profile brittle extrusion process unreasonable reasons

- Head pressure is insufficient On the one hand and mold design; the other is the proportion of the feed and temperature settings, the pressure is insufficient, the material density is poor, it will become loose tissue plastic brittle phenomenon, then adjust the metering feed speed And extrusion screw speed so that the head pressure control in the 25Mpa-35Mpa between.

- Q: What is the steel profile?

- Simply put the profile is installed into a window that can still be seen after the outer surface. Such as the large and small faces of the box. While the middle glass trough installed glass and pressed after the invisible, that is non-visible surface.

- Q: What belongs to plastic profiles

- Plastic profile additives four: processing aids Auxiliaries are mainly developed to improve the performance of plastic molding. Plastic profile processing temperature and decomposition temperature is close, poor mobility, easy to stick in the equipment on the coking, so the production of plastic profiles need to add a certain amount of processing aids to overcome the defects of plastic profiles themselves. Plastic profile additive five: light stabilizer The light stabilizer can inhibit the photooxidation degradation reaction of the polymer by shielding and absorbing ultraviolet rays, quenching and exciting energy to capture free radicals, so as to give the products a good light stabilizing effect and prolong their service life. Plastic profile additives six: filler The filler is a solid additive that is different in composition and structure from plastic, also known as fillers. To improve the physical and mechanical properties of plastic and reduce the cost of plastic has a significant effect and economic value. Plastic profile production formula to add filler, plastic profiles can be heated after the size of the change in the rate of change, increased impact strength, increased rigidity, while also reducing production costs.

- Q: The main features of steel profiles

- Plastic steel profile referred to as steel, the main chemical composition is PVC, it is also called PVC profiles. Is widely used as a new type of building materials, because of its physical properties such as rigidity, flexibility, corrosion resistance, excellent anti-aging properties, is usually used as copper, zinc, aluminum and other non-ferrous metals excellent substitutes.

Send your message to us

Fiberglass signs pile warning signs

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords