Glass steel pipes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass steel pipes

To illustrate, a glass steel buried pipeline foam construction

1, direct buried insulation pipe can be widely used in heating, geothermal, refrigeration, municipal construction, oil and other industrial sectors, adding flame retardant protective layer can also be used for overhead pipeline.

2, the depth of burying must ensure that load ten tons truck safety through, as far as possible, reduce heat loss, shall be laid in the ice below the line, different regions should be based on different conditions of the region specific treatment.

3, pipe trench excavation size should guarantee between the tubes, 200-250 mm interval left between the pipe and the trench wall, in order to on-site installation and joint treatment, gully bottom brick soil compaction, when necessary, available sand bedding.

4, direct buried pipe on the road, the laying depth, just not backfill soil covering is made into the trench forms in the pipe bedding, reinforced concrete plate groove or concrete casing treatment.

5, between the pipe and pipe, using welding (glass pipe connection technology and pressure test standards set separately) pipe after installation, pressure test (9 /cm L) 10 minutes buck 0.5 kg /cm - qualified, should maintain the ditch bottom water and installation of pipe welding joint, made after fully cured (48 hours) will be put into the ditch bottom pipeline, so as not to not make joint processing into the ditch, water soaking pipe joint part and reducing waterproof, anti-corrosion, insulation effect.

6, in the process of installation of the insulation pipe, can be installed on one side, the side to do joint processing, can also be installed all pressure test again after the joint processing.

(1) in order to ensure the joint waterproof, anti-corrosion, insulation effect, to ensure that joint site condition is very necessary.

(2) joint field temperature, in the operation should be kept above 10 degrees, the minimum should not lower than 5 DEG C, the winter is not suitable to do joint processing, rainy days, not suitable for joint treatment, gully bottom wet, water does not do joint processing.

Two, direct buried insulation pipe overview:

Direct buried insulation pipe is mainly composed of four parts.

1: according to the requirement of working steel pipe conveying medium technology respectively adopts a welding steel submerged arc spiral seam steel pipe, seamless steel pipe, double-sided.

The 2 insulation layer: use of rigid polyurethane foam.

3: protective shell is made of high density polyethylene or glass steel.

4 leakage alarm line: manufacturing of directly buried heat insulation pipe, in the insulation layer near the pipe, buried with the warning line, once the pipeline leakage alarm line somewhere, by conduction, can be in a dedicated instrumentation alarm and display the location and the degree of leakage Water Leakage big small, to inform the pipe repair personnel quickly processing Water Leakage, guarantee the safe operation of heat supply network.

Three, direct buried insulation pipe performance:

Direct buried insulation pipe has good mechanical performance and heat insulation performance, usually resistant to the high temperature of 120 DEG C through modification or other insulating material resistant to high temperature of 180 DEG C combination, insulation engineering applicable to all kinds of cold, hot water high temperature pipeline.

Four, the advantages of directly buried heat insulation pipe:

1, reduce project cost.

According to estimates by a relevant department, two pipe heating pipe, under normal circumstances can reduce the project cost 25% (made of glass steel as a protective layer) and 10% (using high density polyethylene as a protective layer around).

2 low heat loss, energy saving.

Direct buried insulation pipe of the thermal conductivity coefficient: lambda =0.013 - 0.03kcal/m - H - oC, other than in the past used pipe insulation material is much lower, the insulation effect is increased by 4~9 times. Again the water absorption rate is very low, about 0.2kg/m2. The reason of low water absorption is due to closed cell polyurethane foam rate around 92%. Low thermal conductivity and low water absorption rate, coupled with the thermal insulation layer and the outside good waterproof properties of high density polyethylene or glass steel shell, has changed the traditional trench laying heating pipeline "wear wet jacket" situation, greatly reducing the overall heat loss of heat supply pipeline, network heat loss is 2%, less than 10% of the requirements of international standard.

3, anti-corrosion, insulation performance is good, the service life is long.

Direct buried insulation pipe because of rigid polyurethane foam insulation layer bonded in the steel sheath, cut off the air and water infiltration, can play a good role in anti-corrosion. At the same time, foaming holes it is closed, water absorption is very small. High density polyethylene shell, glass steel shell has good anti-corrosion, insulation and mechanical properties. Therefore, the work pipe sheath hard to erosion of the outside air and water. As long as the internal pipeline water treatment, according to foreign information, directly buried insulating pipe service life can reach more than 50 years, the use of 3~4 times higher than the traditional life and trench laying overhead laying.

4 an area of small, fast construction, is beneficial to environmental protection and reduce the construction people.

Don't need laying large trench buried heating pipe, only the people buried underground heat insulation pipe, thereby greatly reducing the area, reducing the volume of earth excavation about 50% above, to reduce the amount of 90% civil masonry and concrete. At the same time, heat preservation tube processing and on-site trench parallel, simply field joints, can greatly shorten the construction period. Due to the reduction of the brick, cement, sand and gravel, the remnant soil of transportation, thereby reducing the exhaust emission in the process of construction quantity, dust emission, noise emissions, so as to protect the environment.

5, security

At present, in addition to direct buried insulation pipe production outside of China, are equipped with leakage alarm line, once the pipeline leakage alarm line somewhere, by conduction, can show the insulation pipe seepage, leakage and leakage extent accurate position in the special detecting instruments, the pipe section to inform the inspection personnel quickly processing infiltration leakage. To ensure the safe operation of heat supply network. Domestic production of thermal insulation pipe leakage current alarm line end design, need to fill this blank.

Five, direct buried insulation pipe summary:

The total

- Q: Steel windows and aluminum windows compare which is more expensive

- Lighting performance: Plastic window window lighting performance than the aluminum window difference, the block of a single component shading area than the aluminum window about 10%, vision and decorative effect is poor, is not conducive to building energy saving.

- Q: Plastic doors and windows and plastic windows do not like?

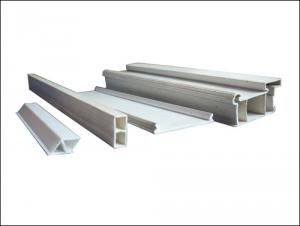

- Glass fiber reinforced plastic (FRP) doors and windows 1) abroad to alkali-free glass fiber reinforced, the product surface finish is better, no need to deal with the system can be used directly to the window. Domestic self-developed glass fiber reinforced plastic doors and windows profiles generally with alkali glass fiber reinforced, the surface of the profile after grinding, available electrostatic powder coating, surface coating and other technical processes, access to a variety of colors or texture of the decorative effect. The following are the same as the " 2) Do not use high-alkali glass fiber made of profiles. The following are the same as the " 3) FRP doors and windows profiles have a high longitudinal strength, under normal circumstances, you can not enhance the steel. But the doors and windows size is too large or high wind pressure requirements, should be based on the use of requirements to determine the enhanced approach. The transverse strength of the profile is low. Fiberglass doors and windows frame for the assembly of the turret, the joints need to use sealant seal to prevent leakage of the gap.

- Q: PVC plastic profiles dip in the seam, how to deal with seamless docking

- Stabilizer too much or too little stabilizer is to inhibit the degradation, or with the release of hydrogen chloride reaction and to prevent the discoloration of PVC processing. Stabilizer according to the different types of different, but the total point, the amount of excessive will delay the material of the plasticization time so that the material export mold when the plastic is not, the formula system between the molecules are not fully dissolved, Its intermolecular structure is not strong cause. And the amount of too little will result in the formulation of relatively low molecular weight degradation or decomposition (also can be said to be plasticized), the stability of the intermolecular structure of the various components of the damage. So the amount of stabilizer will also affect the impact strength of the profile, too much or too little will cause the profile strength caused by the phenomenon of brittle profile.

- Q: What is the quality of plastic steel profiles in the end?

- 08 years to now has been doing the money, it began to have no conch and Shide famous, but it is higher than the other brands, the reason it is a high proportion of plastic, that is less talc powder, the other three sealed pad The bridge is split, so that the fan does not account for the proportion. Speaking of two-color co-extruded, it is the technology is ASA technology is always the most leading, there is no fade, and gorgeous and glossy, which is other profiles can not be compared, I used to vote in the tender angle, , Shide, Zhongda, Huaan, ... .... 10 years did appear broken material situation, has not yet been found.

- Q: The difference between steel and aluminum alloy profiles

- Plastic windows are easy to weather, aluminum alloy will not. If you want to be insulated when you do windows with double glass

- Q: Is the powder produced when the crushed plastic is crushed?

- 1, plastic shredders and power units to be installed firmly. If you need plastic crusher long-term fixed operation, it should be fixed on the basis of cement; if you need plastic crusher flow operation, the unit should be installed in the angle made of iron on the base, and to ensure that the power machine (diesel or motor) and plastic The pulley groove of the crusher is in the same plane of rotation. 2, after the installation of plastic crusher to check the Department of fasteners fastening, if loose to be given to tighten. Also check the belt tightness is appropriate. 3, plastic shredder before starting, first hand rotation of the rotor, check the claws, hammer and rotor operation is flexible and reliable, broken room with or without collision phenomenon, whether the direction of rotation of the rotor and arrows in the same direction, Plastic crusher lubrication is good. 4, do not casually replace the pulley, to prevent the speed is too high to cause the explosion chamber explosion, or too low speed affect the efficiency of the pulverizer. 5, plastic shredder should be maintained after the first start idle 2 ~ 3min, no abnormal phenomenon after feeding work. 6, the work should always pay attention to the operation of the plastic crusher, first of all, to be uniform to prevent the blockage of waste room; Second, do not work for a long time overload. If you find a vibration, noise, bearing and body temperature is too high, such as spraying out of the phenomenon, should immediately stop checking, troubleshooting can continue to work.

- Q: Plastic doors and windows and plastic doors and windows have anything to do

- American doors and windows: the main formula for the use of environmentally friendly organic tin heat stabilizer, to avoid the production, processing, use of lead salt toxicity of the drawbacks; development for the multi-cavity section, the second is to reduce the profile wall thickness, 1.80mm; while increasing the number of internal reinforced steel and the chamber, the chamber generally have 9 to 13. In addition to reducing the strength of profiles, but also improve the thermal insulation and sound insulation effect. The sliding window for the frame package fan, improved the sealing and safety performance, cancel the fan pulley, reduce the fan section at the same time, the window lighting performance has been improved. Developed a standard installation method for pulling windows and new mounting wings. In addition the market has a total of steel and plastic doors and windows, plastic and steel machinery is a combination of new materials.

- Q: What is the broken bridge of aluminum? What are the characteristics?

- Broken bridge aluminum bridge is actually aluminum material, but in the middle of the aluminum through the insulation bar, the aluminum cut off the formation of broken bridge, which is characterized by: 1, broken bridge aluminum insulation is good, good air tightness: aluminum-plastic composite profiles in the plastic thermal conductivity is low, good insulation effect, coupled with a good air tightness, in the cold area despite the outdoor minus tens of degrees, Indoor is warm as spring. ?????? 2, broken bridge aluminum sound insulation is good: its structure has been carefully designed, seams tight, using the insulating glass. Test results The sound insulation standard is: 30db, in line with the relevant noise material standards. ?????? 3, broken bridge aluminum is not easy to deformation, impact resistance: the broken aluminum and aluminum plastic composite profile of the outer surface of aluminum alloy material, so it is much stronger than the impact resistance of plastic window profiles, long years of use is not easy to deformation.

- Q: How to identify the installation of plastic or plastic

- Plastic steel because there are iron, so use the magnet to identify. Another: steel easy to change line, now mostly switch to color steel or better.

- Q: Plastic doors and windows profiles

- The inherent quality of the profile and its reasonable structural design are the prerequisites for the manufacture of high-performance plastic windows. First of all, there must be good formula and high-quality raw materials and advanced production technology to ensure the quality of profiles. In addition from the structure of the profile of a single cavity and multi-cavity PVC plastic profiles, the cavity can be designed ribs, ribs, boss, etc., can be divided into two cavities cavity, three chamber or multi cavity, Can be better from the role of thermal insulation, on the other hand can make the cavity have different purposes, and some used to fix the rigidity of the steel lining, and some used to set the drainage chamber, and some internal ribs can be prevented Profile deformation, the inner ribs can improve the rigidity of the profile, increase the inertia moment of profiles, and improve the impact resistance of profiles.

Send your message to us

Glass steel pipes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords