Diethylene Glycol Dibenzoate DEDB Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16.8

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product performance:

Polyol Benzoate (DEDB) is colorless or pale yellow transparent oily liquid, water-insoluble, soluble in aromatic hydrocarbons, ketones and ethers, and has good compatibility withpolyvinyl chloride, ethylene - vinyl acetate copolymer, poly vinyl acetate, polymethylmethacrylate, polyvinylbutyral, nitrocellulose, and ethyl cellulose, etc.

Product application:

Polyol Benzoate(DEDB) is an environmentally friendly plasticizer with the characteristics of strong solubility, good compatibility, low volatility,resistant to oil, water, light, pollution etc. It is suitable for processing PVC flooring material, plastisol, artificial leather, cable material, soft and hard pipe, shoes material, rubber strips, synthetic rubber, and paint, printing ink, etc. It has a better plasticized effect if it is used together withDOP or DBP, and has greatly achieved the purpose of reducing cost .

Product quality index

Item | First grade | Second grade |

Chroma(APHA) ≤ | 50 | 60 |

Ester % ≥ | 99.5 | 90.0 |

Density(20°C)g/ | 1.120-1.126 | 1.172-1.78 |

Acidity(as benzene dicarbonic acid) % ≤ | 0.01 | 0.02 |

Flash Point °C ≥ | 195 | 192 |

Loss on heat(125°C,2 hours)% ≤ | 0.3 | 0.5 |

Chroma after heat treatment | 80 | 100 |

Specifications

1. Direct producer with 15 years experience

2. ISO9001:2000

3. High quality, lower price and best service

4. New plasticizer

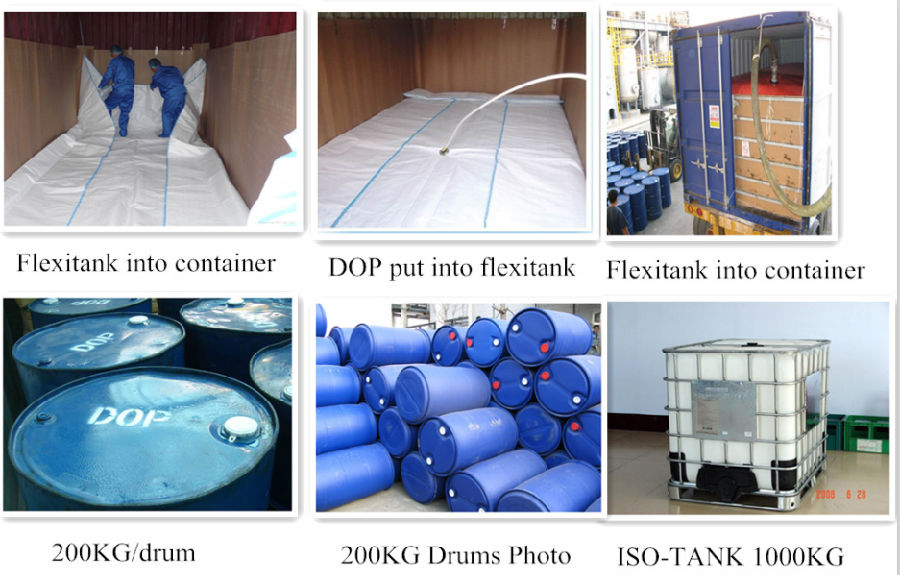

Packaging: IBM, net weight: 1000 kg.

Our Factory:

Our Factory:

- Q:Chemical reaction plus catalyst on the △ H no effect

- Since the addition of the catalyst only accelerates the reaction process and does not have an effect on the reaction product and the reactants

- Q:how could scientists know the exact catalyst for every reactions??? THANX sooo much

- Believe me, nema, there's no way that we chemists know the best catalyst for every reaction. That would be simply impossible. However, from the type of reaction, the reactants, products, reaction conditions, solvents, etc. and from one's experience and the literature (papers and patents) one can get a good idea for most reactions of the type of catalyst that has worked for similar systems. One then starts off with a catalyst from the literature and modifies or changes it if improvement is needed based on chemical principles that one learns. There are also some theoretical calculations that can be made. Sometimes they work and sometimes they don't :) If it is an industrially important process like the Haber process for making ammonia from nitrogen gas and hydrogen gas, there may be thousands of catalysts which have been tried and evaluated. New minor improvements are being made every day. When a company does find a very good catalyst for an important reaction, often they keep it a trade secret. The good catalyst can make a huge difference in how commercially successful a particular process is. That's a large part of what chemical engineers do. You may never know if you have the best catalyst. The most you can hope for is one that is good enough. So it's a few parts personal knowledge, a few parts literature, a couple of parts theory, a lot of experimentation and often, more than not, a little luck. :)

- Q:What is the principle of the catalyst? Why can change the rate of chemical reactions and their own without any change

- The catalyst can be used as the reaction of the original reaction into multiple reactions, such as two, then the catalyst can be the first reaction of the product, while the second reaction of the reactants, then the overall point of view, the amount of catalyst No change, is to change the reaction process.

- Q:High school chemistry, catalyst activation energy map

- Catalytic reaction is the reaction of the first reaction with the catalyst or attached to the catalyst to form intermediates, and then further reaction to produce products and catalysts, so the amount of catalyst in theory is the same! The activation of these two processes can be reduced! So there will be two peaks! Can be simplified as a peak!

- Q:What is the quality of the catalyst in the chemical reaction, for example, 34.3 g before the hydrogen peroxide reaction, 32.7 g after the reaction, and how much is the catalyst mass?

- You can not calculate this question, the quality of the catalyst before and after the same reaction, how much reaction before the reaction on how much

- Q:Co and No form a chemical equation for Co2 and No2 under the action of a catalyst

- Write the catalyst on the horizontal line, where NO is the oxidant and CO is the reducing agent

- Q:Please make it simple because I need it for school and please give to examples for the second part Thanx :D

- A catalyst is a substance that speeds up the rate of a chemical reaction with itself being chemically unchanged at the end of the reaction. They are useful as they help to lower the minimum amount of energy needed ( also known as activation energy) to start the reaction. Hence, by lowering the activation energy of the reaction, they help to speed up the rate of reaction. For example, in the Haber process for the manufacture of ammonia, the catalyst iron is added to speed up the rate of reaction between hydrogen gas and nitrogen gas. Otherwise, the reaction would have proceeded much more slowly. Another example is the catalyst nickel used in the manufacture of margarine and vanadium (V) oxide for manufacturing sulfuric acid. As catalyst remain chemically unchanged after a reaction, they can be reused again and hence, they are required in minute amounts. An example is the washing powder used in washing clothes, they help to remove food stains by digesting the proteins in food. They can be reused after each reaction and hence, you do not need to add in the whole packet of washing powder but only a few spoonful.

- Q:Is the chemical reaction rate constant related to the amount of catalyst used?

- In fact, the catalyst is to participate in the reaction (junior high school textbooks do not respond is to allow students to understand), but the reaction to the final return to the original state.

- Q:The size of △ H in the thermochemical reaction equation is related to the use and unused catalyst

- It does not matter

- Q:What are the requirements for the catalyst for the chemical industry?

- Generally find a few, according to the cost and cost of cost, choose cost-effective

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Diethylene Glycol Dibenzoate DEDB Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16.8

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products