DI Pipes in Water Infrastructure,Ductile Iron Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

DI Pipes in Water Infrastructure

Ductile iron pipe is a pipe made of ductile iron commonly used for potable water transmission and distribution.

Specifications:

1. ISO 2531 & EN 545 Standard

2. K8, K9, K10 C Class

3. Internal Linings: Portland Cement

4. External Coating: Bitumen/ Epoxy

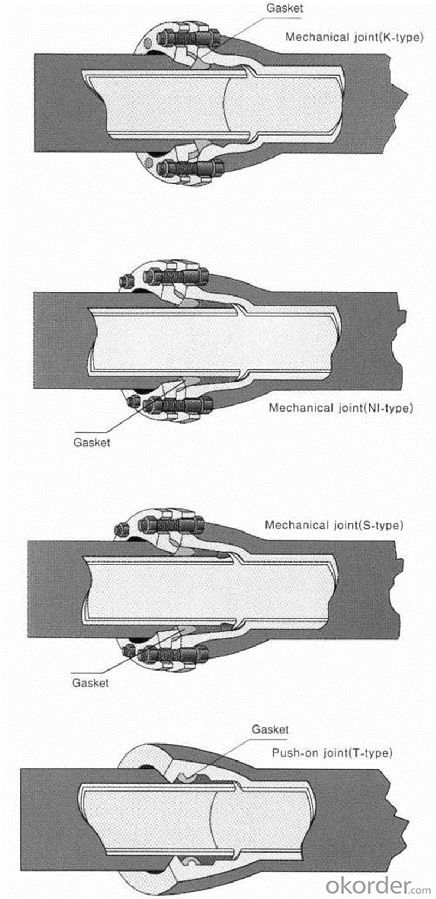

5. Joint Type: T Joint, K Joint, N1 Joint, MJ Joint and Flange Joint.

| DN(mm) | OD(mm) | Wall Thickness(mm) | Weight of Socket (kg) | Unit Weight for Barrel (kg/m) | Total Weight(kg) (Standard Length=6000mm) | ||||||

| K8 | K9 | K10 | K8 | K9 | K10 | K8 | K9 | K10 | |||

| 80 | 98 | 6 | 6 | 6 | 3.7 | 12.2 | 12.2 | 12.2 | 76.8 | 76.8 | 76.8 |

| 100 | 118 | 6 | 6.1 | 6.1 | 4.7 | 14.9 | 15.1 | 15.1 | 94.1 | 95.4 | 95.4 |

| 150 | 170 | 6 | 6.3 | 6.3 | 8.5 | 21.8 | 22.8 | 22.8 | 139.4 | 145.4 | 145.4 |

| 200 | 222 | 6 | 6.4 | 6.4 | 10.9 | 28.7 | 30.6 | 30.6 | 183.6 | 194.6 | 194.6 |

| 250 | 274 | 6 | 6.8 | 7.5 | 15 | 35.6 | 40.2 | 44.3 | 228.8 | 255.8 | 280.8 |

| 300 | 326 | 6.4 | 7.2 | 8 | 22.2 | 45.3 | 50.8 | 56.3 | 293.3 | 326.3 | 360.3 |

| 350 | 378 | 6.8 | 7.7 | 8.5 | 26.5 | 55.9 | 63.2 | 69.6 | 361.8 | 405.8 | 443.8 |

| 400 | 429 | 7.2 | 8.1 | 9 | 32.5 | 80 | 75.5 | 83.7 | 433 | 482 | 532 |

| 500 | 532 | 8 | 9 | 10 | 50.6 | 92.8 | 104.3 | 116 | 607.8 | 676.8 | 743.8 |

| 600 | 635 | 8.8 | 9.9 | 11 | 71.9 | 122 | 137.3 | 152 | 803.6 | 894.6 | 983.6 |

| 700 | 738 | 9.6 | 10.8 | 12 | 85.3 | 155 | 173.9 | 193 | 1015 | 1129.2 | 1243.2 |

| 800 | 842 | 10.4 | 11.7 | 13 | 108.7 | 192 | 215.2 | 239 | 1261 | 1400.1 | 1543.1 |

| 900 | 945 | 11.2 | 12.6 | 14 | 140.1 | 232 | 260.2 | 289 | 1532 | 1701.1 | 1874.1 |

| 1000 | 1048 | 12 | 13.5 | 15 | 174.3 | 275 | 309.3 | 343 | 1824 | 2030 | 2234 |

| 1200 | 1265 | 13.6 | 15.3 | 17 | 267.5 | 374 | 420.1 | 466 | 2512 | 2787.8 | 3063.8 |

- Q: Steel plastic pipe, ductile iron pipe, steel pipe difference

- The utility model has the advantages of wide application range, more connecting modes, suitable for most occasions, good sealing property, proper material selection and anticorrosion treatment, and can greatly increase the corrosion resistance.

- Q: How are ductile iron pipes restrained against axial thrust forces?

- Ductile iron pipes are typically restrained against axial thrust forces through the use of various mechanical joint systems. These joints, such as the push-on joint or the restrained joint, provide a secure connection between the pipes, preventing movement and ensuring structural integrity. Additionally, methods like concrete thrust blocks or anchor blocks are often used to further restrain the pipes and counteract any axial thrust forces that may be exerted on them.

- Q: Are ductile iron pipes suitable for trenchless installation methods?

- Yes, ductile iron pipes are suitable for trenchless installation methods. Ductile iron pipes are known for their strength, durability, and flexibility, making them ideal for trenchless installation methods such as horizontal directional drilling (HDD) and pipe bursting. HDD involves drilling a small pilot hole underground and then pulling the ductile iron pipe through the hole, without the need for extensive trenching. Ductile iron pipes can withstand the pulling forces exerted during this process and can be easily guided through the underground path. Pipe bursting is another trenchless method where an existing pipe is replaced by breaking it apart while simultaneously pulling a new ductile iron pipe into place. The strength and flexibility of ductile iron pipes allow them to withstand the force required to burst the existing pipe and replace it with minimal disruption to the surrounding area. In both these trenchless installation methods, ductile iron pipes offer several advantages. They have a high resistance to corrosion and can withstand high-pressure applications, making them suitable for a wide range of underground environments. Ductile iron pipes also have a long service life, reducing the need for frequent replacement and maintenance. Overall, ductile iron pipes are a reliable and suitable choice for trenchless installation methods, providing efficient and cost-effective solutions for underground pipe installations.

- Q: What is the cost of ductile iron pipes compared to other pipe materials?

- The cost of ductile iron pipes can vary depending on various factors such as size, length, and supplier. However, in general, ductile iron pipes tend to be more expensive compared to other pipe materials such as PVC (polyvinyl chloride) or steel. This is mainly due to the manufacturing process and the inherent qualities of ductile iron that make it a durable and reliable choice for various applications. Ductile iron pipes are known for their high tensile strength, resistance to corrosion, and durability, making them suitable for carrying potable water, wastewater, and other fluids under high pressure. The production process of ductile iron involves adding magnesium to cast iron, which results in improved strength and flexibility. This additional process, along with the quality of the material, contributes to the higher cost. On the other hand, pipes made from materials like PVC or steel can be less expensive. PVC pipes are lightweight, easy to install, and relatively inexpensive, making them a popular choice for low-pressure applications such as irrigation or drainage systems. Steel pipes, known for their strength and durability, are often used in high-pressure applications but come at a higher cost than PVC. Ultimately, the cost of ductile iron pipes may be higher initially, but their longer lifespan and reliability can offset the investment over time. Additionally, factors such as the specific project requirements, local regulations, and availability of materials can also influence the overall cost comparison between ductile iron pipes and other pipe materials.

- Q: How are leaks repaired in ductile iron pipe?

- Leaks in ductile iron pipe are typically repaired by cleaning and preparing the area around the leak, applying a suitable sealant or epoxy, and then securely fastening a repair clamp over the affected area. This clamp provides a tight seal and prevents any further leakage.

- Q: How are ductile iron pipes tested for hydrostatic pressure?

- Ductile iron pipes are commonly used for water and wastewater applications due to their strength and durability. To ensure the quality and reliability of these pipes, they undergo hydrostatic pressure testing. Hydrostatic pressure testing involves subjecting the ductile iron pipes to internal pressure higher than their normal operating pressure. This is done to assess their ability to withstand the maximum pressure they are expected to encounter during their service life. The testing process typically begins with the selection of a sample set of pipes from a production batch or shipment. These samples are carefully prepared by removing any surface coatings or debris that could affect the accuracy of the test results. Next, the prepared samples are placed within a specially designed test rig or test line. The test rig is equipped with all the necessary connections, valves, and gauges to control and monitor the test conditions accurately. Once the samples are secured in the test rig, water or another suitable test fluid is slowly introduced into the pipes. The pressure is then gradually increased to a predetermined level, typically exceeding the expected operating pressure by a certain factor. This elevated pressure is maintained for a specified duration, usually for several hours, to assess the pipes' structural integrity and leak resistance. During the test, the pipes are closely monitored for any signs of leakage, deformation, or failure. Skilled technicians or engineers observe the pressure gauges and visually inspect the pipes for any visible defects or abnormalities. Additionally, automated systems may be employed to continuously record and analyze the pressure readings, ensuring accurate data collection. After the specified test duration, the pressure is gradually released, and the pipes are carefully inspected for any permanent deformation or residual stress. This inspection may involve visual examination, dimensional measurements, or even non-destructive testing techniques such as ultrasonic testing or magnetic particle inspection. The test results are then evaluated against the relevant industry standards or specifications to determine the pipes' compliance with safety and performance requirements. If the pipes pass the hydrostatic pressure test, they are deemed suitable for their intended application. However, if any issues or failures are identified, further investigation, analysis, or corrective actions may be necessary before the pipes can be approved for use. Overall, hydrostatic pressure testing plays a crucial role in ensuring the quality and reliability of ductile iron pipes. By subjecting these pipes to rigorous testing procedures, manufacturers can provide customers with pipes that meet the highest standards of safety and performance.

- Q: What is the cost of ductile iron pipe compared to other pipe materials?

- The cost of ductile iron pipe compared to other pipe materials can vary depending on various factors such as the size, length, and specific requirements of the project. However, generally speaking, ductile iron pipe tends to be more expensive than some of the alternative pipe materials such as PVC or HDPE (high-density polyethylene) pipes. Ductile iron pipe is known for its exceptional strength and durability, making it suitable for a wide range of applications including water distribution, wastewater systems, and industrial piping. Its robustness and longevity contribute to its higher cost compared to other pipe materials. On the other hand, PVC and HDPE pipes are often more affordable options due to their lower production and material costs. Additionally, these materials are lightweight, easy to install, and resistant to corrosion, which can lead to cost savings during installation and maintenance. It is important to note that while ductile iron pipe may have a higher upfront cost, its superior strength and longevity can result in long-term cost savings by minimizing the need for frequent repairs or replacements. The choice of pipe material should be made considering the specific project requirements, budget constraints, and the anticipated lifespan of the infrastructure.

- Q: Can ductile iron pipes be used for rainwater harvesting systems?

- Certainly, rainwater harvesting systems can utilize ductile iron pipes. Renowned for their robustness and resilience, ductile iron pipes prove to be fitting for a range of purposes, including rainwater harvesting. These pipes exhibit exceptional resistance to corrosion and are capable of withstanding considerable pressure, thereby ensuring the efficient conveyance of rainwater from the point of collection to storage tanks or distribution networks. Moreover, their impressively long lifespan diminishes the necessity for frequent replacements, rendering them a cost-effective option for rainwater harvesting systems.

- Q: Can ductile iron pipes be used in areas with high water velocity?

- Yes, ductile iron pipes can be used in areas with high water velocity. Ductile iron pipes are known for their strength and durability, making them suitable for handling high water velocities and pressures. They have a high resistance to corrosion and can withstand the forces generated by fast-moving water. Additionally, ductile iron pipes are designed to have smooth internal surfaces, which helps in reducing friction and minimizing the impact of high water velocity on the pipe. However, it is important to ensure proper installation and maintenance practices to maximize the performance and longevity of the ductile iron pipes in high water velocity areas.

- Q: How are ductile iron pipes protected from external damage?

- Ductile iron pipes are protected from external damage through the application of protective coatings. These coatings act as a barrier, shielding the pipes from corrosion and other forms of external damage. Additionally, the pipes may be encased in concrete or installed in a casing pipe to provide further protection against external forces and impacts.

Send your message to us

DI Pipes in Water Infrastructure,Ductile Iron Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords