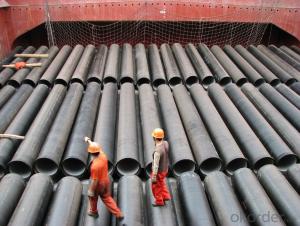

Ductile Iron Pipe On Sale Made In China DN100

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Packaging & Delivery

Packaging Detail: | DN80-300 bundled with steel belt ( the bundle size see the product detail part) DN400-1200 are in bulk |

Delivery Detail: | at least 5days for MOQ |

2.Specifications

Ductile iron pipe comply with ISO2531/EN545

1)We are factory

2)Best quality

3)Competive price

4)On time delivery

3.Features:

Facilitating high resistance to loadings, pressure and vacuum with high tensile strength,

Enabling high resistance to corrosion,

Not requiring cathodic protection,

Less operating cost since cast pipes have larger nominal diameter than polyethylene pipes.

Being the best pipe in case of an earthquake, with its ability of resilience and resistance to impacts without deformation,

Long product life, exceeding 50 years,

Preserving the quality of water with healthy interior coating.

4.Applied Standards:

General Design | ISO 2531 |

Internal Lining | ISO 4179 |

External Coating | ISO 8179 |

Polyethylene Coating (Optional) | ISO 8180 |

5.Joint Types:

Push-on Type | TYT Type |

Standard Type |

6. Diameters:

Pipes | Ø80 – Ø1200 mm (L = 6m, and 5.7m) |

Fittings | Ø80 - Ø2200 mm |

7. Wall Thickness:

Pipes | C and K classes |

Fittings | Class K10 - K12 |

8.Test Pressures:

Pipes | for Ø80 - Ø300 mm | 50 bar / 40 bar |

for Ø350 - Ø600 mm | 40 bar / 30 bar | |

for Ø700 - Ø1000 mm | 32 bar / 25 bar | |

for Ø1100 - Ø2600 mm | 25 bar |

Fittings | for Ø40 - Ø300 mm | 25 bar (*) |

for Ø350 - Ø600 mm | 16 bar | |

for Ø700 - Ø2600 mm | 10 bar | |

(*16 bar for fittings with PN10 flanges) | ||

9.Materials:

Pipe | Ductile iron casting, minimum 420 MPa tensile strength |

Internal Lining | Concrete Lining, ISO 4179 |

Socket Internal 10.Lining | 200 micron epoxy coating |

External Coating | 70 micron bitumen coating on 130 gr/m2 zinc coating, ISO 8179 |

Fittings | Ductile iron casting, minimum 420 MPa tensile strength |

Internal Lining | Concrete Lining, ISO 4179 |

External Coating | 70 micron bitumen coating on 130 gr/m2 zinc coating, ISO 8179 |

- Q: Can ductile iron pipes be used for geothermal systems?

- Yes, ductile iron pipes can be used for geothermal systems. Ductile iron pipes have excellent strength and durability, making them suitable for handling the high temperatures and pressures typically encountered in geothermal systems. Their corrosion resistance and flexibility also make them a reliable choice for transporting geothermal fluid efficiently.

- Q: Can ductile iron pipes be used in high-temperature applications?

- Yes, ductile iron pipes can be used in high-temperature applications. Ductile iron has excellent heat resistance properties, with a maximum recommended operating temperature of around 450 degrees Fahrenheit. This makes it suitable for a wide range of industrial and commercial applications where high temperatures are involved, including steam, hot water, and thermal oil systems.

- Q: Can ductile iron pipe be used for directional drilling?

- Yes, ductile iron pipe can be used for directional drilling. It is a strong and durable material that can withstand the stresses and forces encountered during directional drilling operations. Its flexibility and resistance to damage make it a suitable choice for this application.

- Q: What is the difference between spheroidal graphite cast iron QT400-15 and QT400-15A? What does the A mean later?

- The front is the material grade, and the back of the A should have special requirements.

- Q: Can ductile iron pipes be used in areas with high soil salinity?

- Yes, ductile iron pipes can be used in areas with high soil salinity. Ductile iron pipes have excellent corrosion resistance and are often used for underground applications, including in areas with high soil salinity. The pipes are specially coated to prevent corrosion and are known for their durability and long service life, making them suitable for such environments.

- Q: Are ductile iron pipes resistant to alkaline attacks?

- Yes, ductile iron pipes are generally resistant to alkaline attacks. The high carbon content and unique composition of ductile iron make it highly resistant to corrosion caused by alkaline substances. This resistance allows ductile iron pipes to be used in a variety of applications where alkaline conditions exist, such as wastewater treatment plants and alkaline soil environments. However, it is important to note that the specific resistance may vary depending on the concentration and duration of exposure to alkaline substances.

- Q: Do ductile iron pipes require internal linings for potable water?

- No, ductile iron pipes do not require internal linings for potable water.

- Q: What are the typical joint sealing requirements for ductile iron pipes?

- The typical joint sealing requirements for ductile iron pipes include the use of rubber gaskets or mechanical joints. Rubber gaskets are commonly used for joint sealing in ductile iron pipes as they provide a reliable and flexible seal. These gaskets are typically made of synthetic rubber materials that are resistant to water, chemicals, and other environmental factors. Mechanical joints, on the other hand, are another common method of joint sealing in ductile iron pipes. These joints consist of a mechanical device that connects the pipes together and provides a watertight seal. Mechanical joints are typically designed to allow for some movement and flexibility, which is especially important in areas where ground movement or settlement may occur. In addition to using rubber gaskets or mechanical joints, it is also important to properly clean and prepare the pipe surfaces before making the joint. This may involve removing any dirt, debris, or old joint material from the pipe ends to ensure a proper seal. The joint should then be assembled according to the manufacturer's instructions, ensuring that the gasket or mechanical joint is correctly positioned and tightened to the recommended torque. Overall, the typical joint sealing requirements for ductile iron pipes involve the use of rubber gaskets or mechanical joints, proper cleaning and preparation of the pipe ends, and following the manufacturer's instructions for assembly. These requirements are essential for ensuring a watertight and durable joint that can withstand the pressures and environmental conditions commonly encountered in ductile iron pipe systems.

- Q: How does ductile iron pipe perform in high-velocity flow conditions?

- The performance of ductile iron pipe is exceptional in conditions with high-velocity flow. It can endure the forces exerted by these flows without experiencing significant damage or failure, thanks to its unique properties like high tensile strength and impact resistance. One advantage of ductile iron pipe is its ability to withstand water hammer, which is a sudden increase in pressure caused by the rapid deceleration or change in direction of water flow. This is particularly crucial in high-velocity flow conditions, where water velocity is significantly higher than normal. Ductile iron pipes are designed to absorb and dissipate the energy generated by water hammer, protecting the pipe and the surrounding infrastructure. Moreover, ductile iron pipe has excellent flow characteristics, ensuring smooth and efficient water transport even at high velocities. This is especially important in applications that require quick transportation of a large volume of water, such as industrial processes or fire protection systems. The smooth interior surface of ductile iron pipe minimizes friction and pressure losses, allowing water to flow freely and efficiently, reducing energy consumption and operating costs. Furthermore, ductile iron pipe is highly resistant to corrosion, which is a common issue in high-velocity flow conditions where the water may contain aggressive chemicals or particulates. The protective lining and coating systems used in ductile iron pipes create a barrier against corrosion, prolonging the lifespan of the pipe and maintaining its structural integrity. In conclusion, ductile iron pipe is ideal for high-velocity flow conditions due to its ability to withstand water hammer, excellent flow characteristics, and resistance to corrosion. Its strength, durability, and reliable performance make it a preferred choice for various applications, ensuring efficient water transport even in demanding environments.

- Q: Why is the cast iron tube lined with cement? Under what circumstances are ductile iron pipes lined with cement, and under what circumstances do not have to be lined with cement?

- Cement lining to protect water quality, reduce loss, improve the service life of the pipeline ductile, ductile iron pipes are generally lined, which the en545 standard specifies the quality of what kind of what kind of cement.

Send your message to us

Ductile Iron Pipe On Sale Made In China DN100

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords